Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

A plastic thermoforming machine heats plastic sheets. It shapes them into useful products. These machines are important in factories today. They help companies save time. They also help companies save money.

Thermoforming uses most of the plastic sheet. This means less waste. Automated systems cut labor costs by almost one third. This makes production faster and easier.

The worldwide market for these machines was USD 1.2 billion in 2023.

Experts think the market will reach USD 2.5 billion by 2032. It will grow about 7.5% each year.

Fast prototyping and shorter wait times make thermoforming popular with many manufacturers.

Plastic thermoforming machines warm up plastic sheets. They shape the sheets into products. This process cuts down on waste. It also helps save money.

Automation and AI make production faster. They also make products better. These tools help companies stay ahead.

Picking the right thermoforming machine is important. It depends on what you need to make. It also depends on the materials you use. Cost is another thing to think about.

Using sustainable materials is now very important. Good practices help the environment. Companies use these to reach green goals.

There are different thermoforming methods. Vacuum and pressure forming are two examples. Each method works for different jobs. They are used for things like packaging and car parts.

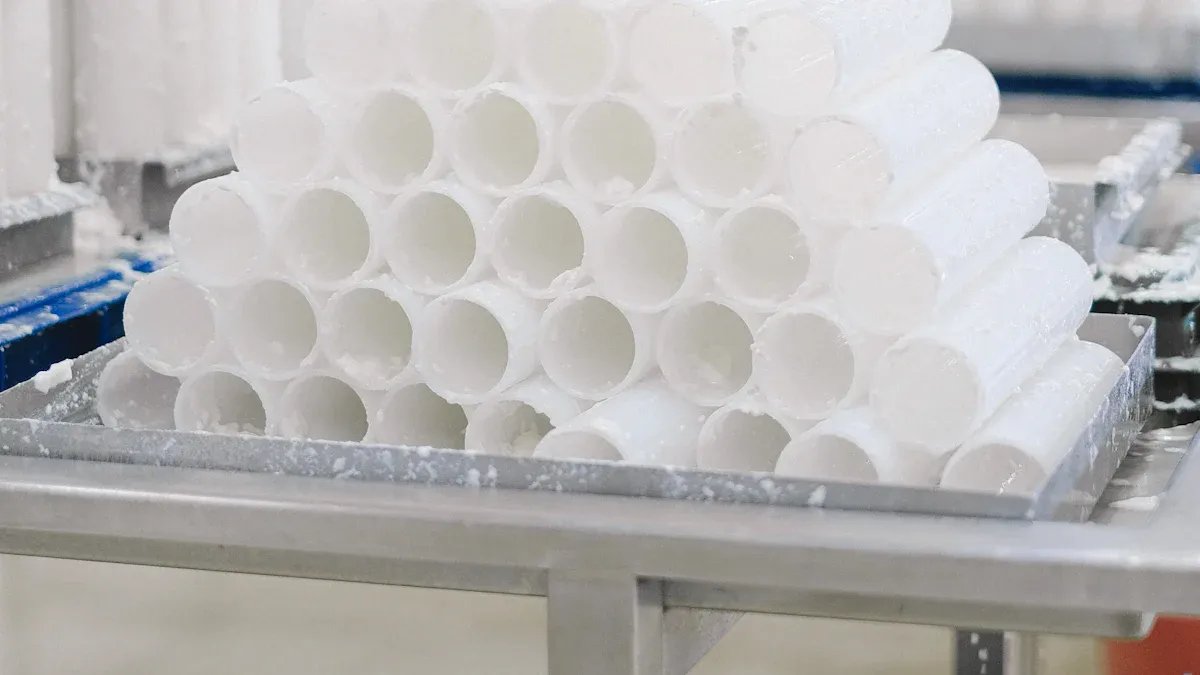

Image Source: unsplash

A plastic thermoforming machine heats plastic sheets until they get soft. The machine then shapes the plastic using vacuum, air pressure, or force. This helps companies make many things, like packaging trays and car parts.

Thermoforming machines warm up thermoplastic materials until they can be shaped. They use vacuum or air pressure to pull the material onto a mold. The machine holds the material in place as it cools and gets hard.

There are different ways to do thermoforming. Each way has its own level of detail and skill. Companies pick the best way based on the plastic and what they want to make.

All plastic thermoforming machines have important parts. These parts work together to shape the plastic.

Heating System: This part makes the plastic sheet soft and bendy.

Clamping Frame: The frame keeps the plastic sheet still while it is heated and shaped.

Forming Station: This area has the mold. The machine pulls the soft sheet over the mold with vacuum, air pressure, or force.

Cooling System: This part cools the shaped plastic so it keeps its new shape.

Trimming Station: This part cuts off extra plastic and finishes the product.

There are different types of thermoforming machines. Rotary machines spin molds in a circle. Shuttle machines move molds back and forth. In-Line Roll-Fed machines use a roll of plastic sheets for nonstop work.

Plastic thermoforming machines have special benefits over other ways of molding. The table below shows how thermoforming and injection molding are different.

| Aspect | Thermoforming | Injection Molding |

|---|---|---|

| Production Speed | Slower, single part per cycle | Faster, multiple cavities possible |

| Cost | Lower tooling costs, aluminum molds | Higher tooling costs, steel molds |

| Material Usage | Uses plastic sheets, more malleable | Uses plastic pellets, less malleable |

Thermoforming uses plastic sheets that are easy to shape. Injection molding uses pellets that need more force to shape. Thermoforming usually costs less because it uses aluminum molds. Injection molding makes more parts faster. Companies pick the best way based on speed, price, and what materials they need.

A plastic thermoforming machine changes plastic sheets into products. Each step helps make sure the products are good and made fast.

Engineering (Intake, Quoting, Design): The team talks about the project and makes plans.

Tooling: Workers build tools to shape the plastic.

Material Selection: Experts pick the best plastic for the job.

Product Verification; Full Production: The team checks if the product works well.

Production: The machine heats and shapes the plastic.

Shipping Logistics: Workers pack and send the finished products.

Note: Planning each step carefully helps companies stop mistakes and save money.

Plastic thermoforming machines use different ways to shape plastic. Each way is good for certain products and jobs.

| Type of Thermoforming | Description | Ideal Applications |

|---|---|---|

| Vacuum Forming | Heats a plastic sheet and uses a vacuum to pull it over a mold. | Automotive parts, medical containers, packaging, retail displays. |

| Pressure Forming | Uses compressed air to press the plastic sheet onto the mold, allowing for more detail. | Bathtubs, utensils, office equipment, medical devices, electronic housings. |

Vacuum forming is good for simple shapes and big parts. Pressure forming is better for detailed and tricky shapes.

Manufacturers pick materials based on what the product needs to do. Some common plastics are:

Polyethylene (PE): It is strong and bendy, good for containers and packaging.

Polyethylene Terephthalate (PET): It does not react with chemicals and is safe for food.

Polystyrene (PS): It is easy to shape and cheap for single-use things.

Polyvinyl Chloride (PVC): It can be used for medical and store items, and can be clear.

Acrylonitrile Butadiene Styrene (ABS): It is tough and does not melt easily, used in cars and electronics.

Acrylic: It is very clear and hard to break, good for windows and displays.

A plastic thermoforming machine can use many of these plastics. This makes it a good choice for many companies.

Plastic thermoforming machines have three main types. These are manual, semi-automatic, and fully automatic. Each type is good for different jobs. Manual machines need people to run them by hand. Semi-automatic machines use some machines and some people. Fully automatic machines work mostly by themselves.

People pick a machine by thinking about speed, price, and control.

| Feature | Manual Machines | Semi-Automatic Machines | Fully-Automatic Machines |

|---|---|---|---|

| Operation | Needs people all the time | Some steps need people | Works by itself, needs little help |

| Production Speed | Slow | Medium speed | Very fast, makes many each hour |

| Consistency | Changes a lot | Some changes from people | Very steady, same every time |

| Initial Investment | Not too expensive | Costs a bit more | Costs a lot at first |

| Operating Costs | High because of workers | Medium, needs more workers | Low, not many workers needed |

| Flexibility and Customization | Not very flexible | Easy to change for new jobs | Hard to change, takes more work |

| Maintenance | Easy to fix | Not hard to fix | Harder to fix, more parts |

Manual machines are best for small jobs or special orders. Semi-automatic machines are faster and can do more things. Fully automatic machines are best for big jobs and make the same thing over and over.

Thermoforming machines can be inline or offline. Inline systems move plastic through each step without stopping. Offline systems stop between steps and may need to heat the plastic again.

| Feature | Inline Thermoforming | Offline Thermoforming |

|---|---|---|

| Workflow | Does not stop, very fast | Stops sometimes, slower |

| Heating | Always hot, saves energy | May need to heat again |

| Output Quality | Very even, looks the same | Can change, not always even |

| Best Use | Big jobs, same products | Small jobs, special products |

Inline systems help factories make lots of things fast. They keep the heat steady and make products that look the same. Offline systems are better for small jobs or special shapes. People can change settings for different products.

Some jobs need special thermoforming machines. These machines do special work and use special materials.

Food companies use machines to make trays and boxes.

Medical companies need machines for clean packaging.

Plant businesses use machines to make pots and trays.

Companies that sell things use machines for displays and cases.

Special machines come in many shapes and sizes. Rotary vacuum formers and single station vacuum formers make big or tricky parts. Airplane and train companies use these machines for panels and covers. Medical and factory equipment makers use them for exact shapes.

Special machines help companies follow rules and make products for many jobs.

Image Source: pexels

Plastic thermoforming machines are very important for packaging. Companies use them to make blister packs, clamshells, and plastic trays.

Blister packs help keep products safe from being opened.

Clamshells snap shut like a shell and protect products well. They also let people see what is inside.

Plastic trays hold things in place when shipping or showing them.

Some machines use heat and pressure to make packages with special shapes and textures. These machines make clamshells, medical trays, blisters, and food boxes.

Thermoforming lets companies make trays and inserts that fit products. This way uses less plastic and costs less than other ways.

Car companies use big plastic thermoforming machines for car parts.

They make door panels, dashboards, glove boxes, and center consoles.

Some outside car panels are now made with thermoformed plastic instead of metal.

Big machines, CNC, and robots help make parts very exact. Thermoforming is a cheap and easy way to make tricky car shapes.

Medical companies use thermoforming for trays, blister packaging, and holders for tools.

Trays keep medical tools clean and safe.

Custom shapes hold special tools and keep them safe when moving.

Thermoformed packages keep out water and dirt. The process can make many sizes and shapes to meet health rules.

Many things people buy use thermoformed parts.

Custom, food, cosmetic, and display packaging are all made this way.

Thermoforming lets companies make new designs fast to match what people want.

| Industry | Custom Use Description |

|---|---|

| Food Packaging Trays | Light trays that stack and keep food safe. |

| Retail Display Inserts | Special trays that show products nicely. |

| Protective Equipment Cases | Hard cases that protect tools and devices. |

| Hot Tub and Spa Shells | Strong, waterproof shells with comfy shapes. |

| Refrigerator Liners | Smooth liners in one piece for easy cleaning. |

| Aircraft Interior Panels | Light panels that follow safety rules. |

| Signage and Display Boards | 3D signs for company names and logos. |

| Recreational Vehicle Panels | Weatherproof panels for inside RVs. |

Plastic thermoforming is great for making hard shapes and cool designs. It works for small or big jobs. It costs less and is faster than other ways.

Factories now use automation and artificial intelligence to make plastic thermoforming machines better. These new tools help companies work faster and make products that are higher quality.

AI and data analytics help teams find ways to work smarter and stay ahead of others.

Automation makes the thermoforming process quicker and improves product quality. This helps companies when they do not have enough workers and makes machines run better.

Dual-arm robots cut parts very accurately. These robots can do many tasks alone, so fewer workers are needed and production speeds up.

Machine learning finds mistakes and helps make products more exact. Companies use these tools to make sure every item is made well.

New ways to save energy lower costs and help the planet, especially for food packaging.

Automation and AI make plastic thermoforming machines smarter and more dependable. These changes help factories make more products with less waste.

Advanced computer-aided design (CAD) systems and digital controls have changed how companies design and use thermoforming machines.

| Feature | Benefit |

|---|---|

| 3D Modeling | Teams make detailed designs with tools like SolidWorks and Autodesk Inventor. |

| Simulation & Analysis | Engineers find problems early and improve how machines work. |

| Material Selection | Designers pick the best materials for strong and efficient products. |

| Real-time Collaboration | Teams work together on platforms like Fusion 360, which makes projects finish faster. |

| Integration with CAM | CAD designs connect right to manufacturing, which means fewer mistakes. |

CAD systems help teams make hard shapes and use materials wisely. Finding problems early saves time and money. Predictive maintenance keeps machines working well and stops long breaks.

Hybrid manufacturing and 3D printing now work with plastic thermoforming machines. This mix brings many good things.

Companies save money when making samples and small batches.

Production gets faster, with quick turnaround times.

Teams test new designs easily and change them when needed.

Special materials fit unique jobs and uses.

Complex shapes are possible with flexible designs.

CNC machining makes products more exact and smooth.

Less material is wasted because only needed parts are made.

Making samples and products skips extra steps, which saves time.

Less scrap and energy use means lower costs.

Teams can fix and redo parts when needed.

Small batches get custom designs quickly.

Hybrid machines cost more at first. The software can be hard to use and needs special tools. Workers must learn both 3D printing and CNC machining skills.

Hybrid and 3D printing give companies more choices and help them react fast to market changes.

Sustainability now shapes the future of plastic thermoforming machines. Companies use new materials to help the environment and meet what customers want.

| Material | Environmental Impact | Performance Characteristics |

|---|---|---|

| Polypropylene (PP) | Lower carbon footprint, uses fewer resources, emits fewer greenhouse gases | Easy to form, stable, durable |

| High Molecular Weight Polyethylene (HMWPE) | Recyclable, low environmental impact | Tough, resists impact, forms well |

| Acrylonitrile Butadiene Styrene (ABS) | Recyclable, energy-efficient production | Tough, versatile, resists impact |

| Polycarbonate | Recyclable, reduces impact through recycling | Clear, strong, resists impact |

| Polyvinyl Chloride (PVC) | Recyclable, energy-efficient production | Versatile, resists chemicals, durable |

Post-consumer recycled plastics use old plastic and lower the need for new plastic.

Bioplastics come from plants and can break down in compost.

Recyclable thermoplastics like PET, HDPE, and PP work well in recycling programs.

Natural fiber composites mix plastic with fillers that break down, which helps composting.

Automation and sustainability trends push companies to make machines that use less energy and create less waste. New models focus on recycled and biodegradable plastics. These changes help companies meet environmental goals and save money.

Sustainable materials and smart machine designs help companies protect the planet and stay ahead of others.

Manufacturers need to think about a few things before picking a machine. They should make sure the machine fits their work, materials, and what they want to make. The table below lists what to look for:

| Criteria | Description |

|---|---|

| Production Requirements | Check what you need to make and what plastic you use. |

| Machine Features | Look at heating, shaping, cutting, and if it works by itself. |

| Cost Considerations | Think about the price and how much you save later. |

| Manufacturer Reputation | Choose a company that is trusted and helps you if needed. |

Tip: Looking at these things carefully helps companies not make expensive mistakes.

Machines that work really well are different from regular ones. They can switch jobs faster, have better controls, and make more things. The table below shows how they compare:

| Feature | High-Performance Models | Standard Models |

|---|---|---|

| Quick-Change Capabilities | Can switch products in less than two hours | Takes more time to switch |

| Mold Change Design | No tools needed, quick-change parts | Needs tools and takes longer |

| Control Systems | Smart controls with saved settings | Simple controls |

| Productivity Features | Works faster, wastes less plastic | Not as many ways to work faster |

| Trim Press Design | Side-loading makes it easy to change tools | Regular way to change tools |

| Customer Demand | People want fast changes | Not as much focus on speed |

A machine with these things helps a company work quicker and make better stuff.

How much a plastic thermoforming machine costs depends on its size and what it can do. Companies also need to think about how much it costs to use and fix the machine. The table below shows price ranges:

| Machine Size Category | Typical Price Range | Key Features |

|---|---|---|

| Small Format (24″ x 48″) | $8,900 – $15,000 | Run by hand, simple heating |

| Medium Format (48″ x 48″) | $13,900 – $25,000 | Can do more, heats in two ways |

| Large Format (48″ x 96″) | $21,900 – $50,000 | For factories, smart controls |

| Fully Automated Systems | $50,000 – $200,000+ | Computer controls, feeds itself, all-in-one |

Other costs to think about are:

Money spent to buy the machine and special parts.

Power, workers, and fixing the machine.

Buying plastic sheets and recycling old ones.

Losing value over time and selling it later.

Time lost when the machine breaks or slows down.

Note: Planning for all costs helps companies not get surprised.

Different jobs need different machines. The best machine depends on what the company makes. The table below shows which machine is best for each job:

| Application | Recommended Machine | Key Features |

|---|---|---|

| Food Packaging | Inline Vacuum Forming Machine | Fast, can work by itself |

| Automotive Components | Pressure Forming Machine | Makes strong, detailed parts |

| Medical Devices | Twin-Sheet Thermoforming Machine | Clean, makes hollow shapes |

| Industrial Products | Rotary Thermoforming Machine | Big, makes lots of parts |

A company should pick a machine that matches what it makes and what it wants to do. This helps them do their best work and save money.

Plastic thermoforming machines help companies work faster. They also help companies waste less plastic. Many companies use recycled materials. Some use 3D-printed molds for quick changes. These changes do not cost much money. Automation and robots make machines work faster. They also help make better products. Advanced controls keep products strong. These controls help reduce waste.

Factories can work up to 30% better with automation.

Machines make custom parts for many jobs, like cars and appliances.

| Industry | Benefit |

|---|---|

| Automotive | Fast parts that are high quality |

| Consumer Products | Custom packaging that is strong |

| Marine | Products that last and resist sun |

If you need more help, some groups can give advice. Best Practices in Custom Thermoforming, Plastik MP, and the Plastics Innovation & Resource Center have experts and resources.

A plastic thermoforming machine makes products from plastic sheets. Factories use these machines for packaging and car parts. They also make medical trays and things people buy.

The machine heats a plastic sheet until it is soft. It pulls the sheet over a mold with vacuum or air pressure. The plastic cools down and keeps its new shape.

| Plastic Type | Common Use |

|---|---|

| PET | Food packaging |

| ABS | Automotive parts |

| PVC | Medical trays |

Each plastic has its own strength and flexibility.

Thermoforming costs less for small jobs and uses easy molds. Injection molding is faster for big jobs and makes detailed parts.

♻️ Yes, many companies recycle plastics like PET and PP. Recycling helps cut down on waste and supports green goals.