Views: 0 Author: Site Editor Publish Time: 2025-09-05 Origin: Site

A thermoforming machine heats up a plastic sheet until it is soft. The machine shapes the plastic into things we can use. It does this by forming, cooling, and cutting the plastic. Many people use things made with thermoforming every day. For example:

| Product Type | Description |

|---|---|

| Custom Packaging | Special packaging made for products of many sizes and shapes. |

| Food Packaging | Strong plastic that keeps food safe when it is moved or handled. |

| Cosmetic Packaging | Safe and tough materials used for creams, powders, and serums. |

| Display Packaging | Fancy displays with shiny finishes to make people want to buy. |

These things show that thermoforming is very important in our daily lives.

A thermoforming machine heats plastic until it gets soft. Then, it uses molds to make things like packages and containers. Thermoforming is faster and costs less than injection molding. This makes it good for making special shapes and big parts quickly. Some plastics used in thermoforming are polypropylene, PET, and PVC. These plastics are picked because they are strong and bend easily. They are also safe for food packaging. The thermoforming process has four steps: heating, shaping, cooling, and trimming. This helps make products fast and creates little waste because of recycling. Packaging, car, and medical industries use thermoforming a lot. They like it because it saves money, can do many things, and is better for the environment.

A thermoforming machine is a tool that shapes plastic sheets. It works by heating a thermoplastic sheet until it gets soft and bendy. The machine then pushes the soft plastic onto a mold to make a shape. Industry rules say a thermoforming machine heats thermoplastic until it can be formed into different shapes. The machine uses a vacuum pump, air, or force to press the plastic onto the mold.

Thermoforming machines help make things we use every day, like food trays, cups, and special packaging. These machines let companies make products fast and easily.

Thermoforming machines are not the same as injection molding machines. In thermoforming, the machine shapes warm plastic sheets over molds. Injection molding machines melt plastic pellets and push the melted plastic into molds with high pressure.

Some main differences between thermoforming and injection molding are:

Thermoforming uses a mold with one side, but injection molding uses two sides.

Thermoforming molds are usually made from cheaper aluminum. Injection molding molds are made from thick, heavy steel.

Thermoforming molds cost less to make because they are lighter and have one side.

These reasons make thermoforming machines a good choice for making packaging and other custom-shaped items.

The thermoforming machine shapes plastic in steps. First, it heats the plastic sheet until it is soft. The plastic is now ready to be shaped. Next, the machine uses air or a vacuum to pull the plastic onto a mold. The mold gives the plastic its shape. The machine holds the plastic in place as it cools and gets hard.

Here are the main steps:

Heat the thermoplastic sheet until it is soft.

Use air or a vacuum to pull the sheet onto a mold.

Hold the sheet in place while it cools and hardens.

During thermoforming, the plastic changes in different ways. The table below shows the main changes:

| Change Type | Description |

|---|---|

| Physical Change | Thermoplastic goes from hard and glassy to soft and rubbery when heated above its glass transition temperature (Tg). This change affects how hard or stretchy it is. |

| Chemical Change | Adding chemicals or fillers can change the Tg, which changes how the plastic reacts to heat. |

| Melting Process | When heated, the plastic’s chains move more. The plastic melts and can form crystals as it cools. |

Thermoforming machines help make many kinds of plastic products. They are used to make things like packaging, trays, and containers. The process is quick and saves money, so many companies use it.

The thermoforming machine starts by heating plastic sheets. It uses special heaters to warm the plastic evenly. There are different types of heaters. Resistance heaters heat the plastic the same all over. Infrared heaters work fast and save energy. Hot air heaters are good for big jobs because they heat large areas.

| Heating Element Type | Function | Advantages |

|---|---|---|

| Resistance Heaters | Make heat by running electricity through special wires | Even heating |

| Infrared Heaters | Use invisible light to warm plastic sheets | Heat up fast, save energy |

| Hot Air Heaters | Blow hot air to warm big areas | Good for heating large spaces |

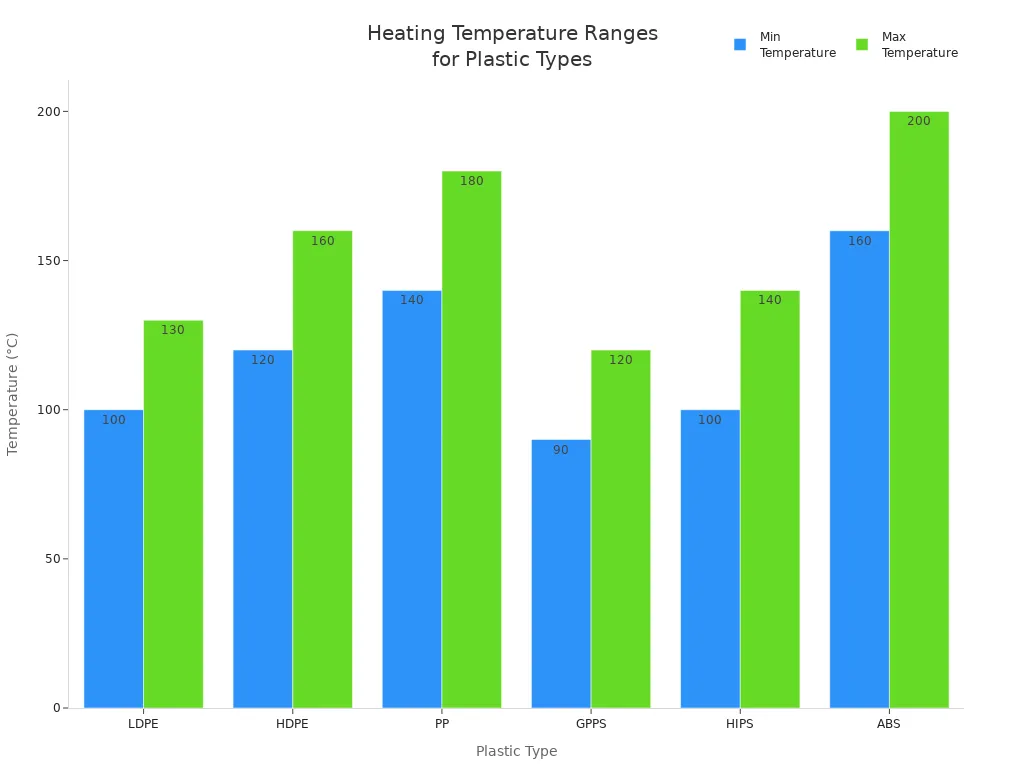

The right temperature depends on the plastic type. LDPE needs to be heated between 100°C and 130°C. ABS needs a higher heat, from 160°C to 200°C. The chart below shows how hot different plastics need to get.

After heating, the machine shapes the soft plastic. There are two main ways to do this. Vacuum forming pulls air out from under the plastic. This makes the plastic press down onto the mold. Pressure forming uses both vacuum and extra air pressure. The extra pressure helps make sharper shapes and textures.

| Feature | Vacuum Forming | Pressure Forming |

|---|---|---|

| Pressure Applied | Uses only vacuum (about 14.7 psi) | Uses vacuum and air (60–100+ psi) |

| Detail Level | Makes simple shapes | Makes detailed shapes |

| Production Speed | Works faster | A bit slower because it is complex |

Vacuum forming is good for simple shapes and quick jobs. Pressure forming is better for making detailed parts but takes more time. The table below shows what is good and bad about each method.

| Feature | Vacuum Forming | Pressure Forming |

|---|---|---|

| Detail and Texture | Not much detail | Lots of detail and texture |

| Cost | Cheaper for small jobs | Costs more but good for details |

| Applications | Best for easy shapes | Good for hard or fancy shapes |

| Speed | Makes things quickly | Slower but looks better |

Tip: Vacuum forming is fast and cheap. Pressure forming is best for fancy or detailed products.

After shaping, the machine cools the plastic on the mold. Cooling helps the plastic keep its new shape. When it is hard, the machine trims off extra plastic. Workers or machines cut away the extra edges, called flash. Trimming can be done with special tools or machines like CNC routers. Tools such as dies, saws, or wheels help cut out the finished part. Many factories use the leftover plastic again to make new things.

Thermoforming turns flat plastic sheets into useful products. Each step—heating, shaping, cooling, and trimming—helps make strong and useful plastic items.

Image Source: pexels

A thermoforming machine has many important parts. Each part helps turn a plastic sheet into a finished product. Every part does a special job in the process.

Heating elements make the plastic sheet warm and soft. Some heaters, like infrared and induction, use less energy. These heaters send heat right to the sheet, so less is wasted. Reflectors and insulation keep heat in the right place. Operators can use lower settings to save energy. This can cut energy use by up to 25%. The heating system must heat the plastic evenly. Even heating helps the plastic form well and stay strong.

The forming station shapes the soft plastic onto a mold. This step gives the container its final look and strength. The station uses pressure or a vacuum to press the plastic. Good control of mold temperature and pressure makes each container the same. The forming station also changes the thickness and surface of the product. If the machine forms the plastic well, the container is strong and smooth.

The cooling system helps the shaped plastic keep its form. Most machines use fans or water to cool the mold and plastic fast. Aluminum molds cool faster than wood or epoxy molds. This is because aluminum moves heat away better. Cooling channels inside the mold help speed up cooling. Faster cooling lets the machine make more containers quickly.

The trimming unit cuts off extra plastic from the container. This step gives the product a neat edge and the right shape. Modern trimming units use servo systems and guides for better cuts. These systems help the machine cut fast and keep the shape right. Good trimming makes the product look nice and last longer. Easy-to-fix trimming units help the machine run without stopping.

Tip: All parts of the thermoforming machine work together. This helps every plastic container meet quality standards.

| Component | Function |

|---|---|

| Heating System | Heats the plastic sheet evenly to the right temperature. |

| Forming Station | Shapes the warm plastic sheet using a mold. |

| Cooling System | Cools the shaped plastic sheet with fans or water. |

| Trimming Station | Cuts off extra plastic to make the final shape. |

| Control System | Checks and changes settings for good quality and efficiency. |

Many plastics can be used in thermoforming. Each plastic has special features for different uses. Some are strong. Others are clear or bend easily. Polypropylene (PP) is the most used plastic in thermoforming. Experts think PP will make up 64% of the market by 2037. PP is liked because it is light and cheap. Companies use PP for food packaging, car parts, and many other things.

Other plastics used are:

PET (polyethylene terephthalate): This plastic is clear and strong. Factories use it for pet fruit containers and other packages.

PVC (polyvinyl chloride): PVC is tough and does not get damaged by chemicals. It is good for trays and clamshells.

PS (polystyrene): PS is easy to shape. It is used for biscuit trays and egg trays.

ABS (acrylonitrile butadiene styrene): ABS is strong and does not break easily. It is used for parts that need to last long.

Note: More people want thermoformed plastics, especially for food packaging and other uses.

Some plastics are better for thermoforming because of their special features. These features help the plastic form shapes like food containers without breaking. Important features are:

Impact resistance: The plastic does not break if dropped.

Thermal conductivity: The plastic heats and cools fast, which helps shape it.

Chemical resistance: The plastic does not react with food or cleaners.

Forming range: The plastic stays bendy at many temperatures.

These features make PP, PET, and PS good for making pet fruit containers, biscuit trays, and egg trays. Companies pick these plastics because they help make safe, strong, and low-cost products.

Image Source: unsplash

Thermoforming has many good points for companies and buyers. Companies like it because it saves both money and time. The table below shows how thermoforming and injection molding are different:

| Advantage | Thermoforming | Injection Molding |

|---|---|---|

| Tooling Costs | Much lower | More expensive molds |

| Production Timeline | Only takes days or weeks | Takes months to design and build |

| Flexibility in Design | Easy to change | Needs a new mold for changes |

| Large Parts | Can make big parts easily | Hard to make big parts |

| Setup Process | Simple and easy to repeat | More steps and harder to set up |

Thermoforming is faster than fiberglass molding. It takes less time and needs fewer workers. This means companies can make more things quickly. Fully-automatic thermoforming machines make lots of products fast. Semi-automatic machines are better for small jobs and give more control.

Thermoforming is also good for the planet. Factories can recycle and use plastic again and again. They cut up leftover plastic and use it to make new things. This helps stop waste and saves materials. New machines use less energy, sometimes up to 85% less than other ways. Thermoformed items are light, so shipping them makes less pollution. These reasons make custom thermoforming popular in many fields.

Note: In 2024, the world market for thermoformed plastic products was worth USD 16.15 billion. Experts think it will grow to USD 24.26 billion by 2030.

Many businesses use thermoforming to make their products. The packaging industry uses it the most, about 33% of the market. Food packaging, clamshells, and blisters are made this way. Car makers use thermoforming for door panels, dashboards, and center consoles. These parts are strong, light, and easy to shape.

| Industry | Notable Products |

|---|---|

| Automotive | Door panels, dashboards, center consoles |

| Medical | Custom trays, packaging, medical devices |

| Packaging | Clamshells, blisters, protective packaging |

Car makers like parts that are light and tough. Thermoforming helps cars weigh less, so they use less gas. The packaging industry likes how fast and flexible thermoforming is. Medical companies use it for safe and clean trays. Other fields, like building and electronics, use thermoforming for special parts too.

The market for thermoforming is growing as more businesses want cheaper and greener ways to make things.

Thermoforming machines turn flat plastic sheets into strong things we use. These machines work fast and can use many kinds of plastics. They help make things for food, medical, and car companies. The table below shows why companies like this process:

| Feature | Description |

|---|---|

| Cost-Effectiveness | It costs less to make tools and is quick for big jobs. |

| Versatility | It works with lots of plastics and designs for many uses. |

| Sustainability | Many items can be recycled, which is good for the earth. |

We see things made by thermoforming every day, like food trays and car parts.

A thermoforming machine makes things like food trays and car parts. It also makes clamshell packaging and medical trays. Many companies use it to make special shapes for packaging and containers.

Vacuum forming shapes plastic by pulling air out from under it. Pressure forming uses both suction and extra air to shape the plastic. Pressure forming makes the finished product have sharper details and textures.

Yes, factories can reuse leftover plastic from thermoforming. They collect scraps and grind them into small pieces. These pieces get mixed with new plastic to make more products. This helps save money and reduces waste.

Polypropylene, PET, PVC, PS, and ABS are good for thermoforming. These plastics heat up and cool down fast. They do not break easily and keep their shape after forming.

Thermoforming uses plastics like PP and PET that are safe for food. These plastics do not react with food. They help keep food fresh and safe when stored or moved.