Views: 0 Author: Site Editor Publish Time: 2025-11-26 Origin: Site

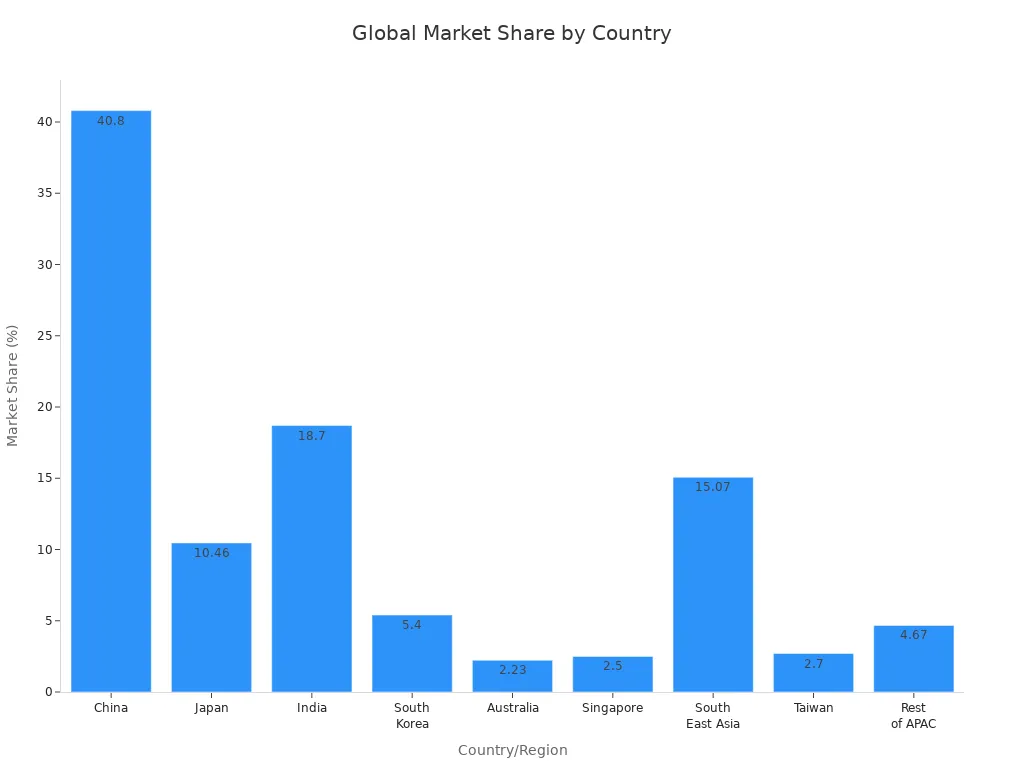

Chinese Thermoforming Machine Manufacturers are very important in the world packaging equipment market. The table below shows that China is the leader. China has a market share of 40.80%. This is much higher than other countries:

| Country | Market Share (%) |

|---|---|

| China | 40.80 |

| Japan | 10.46 |

| India | 18.70 |

| South Korea | 5.40 |

| Australia | 2.23 |

| Singapore | 2.50 |

| South East Asia | 15.07 |

| Taiwan | 2.70 |

| Rest of APAC | 4.67 |

New technology, more industries using these machines, and better ways to make products help Chinese manufacturers look good around the world. Hengfeng is special because it focuses on new ideas and making high-quality products.

China leads the thermoforming machine market with a 40.80% share. This is much higher than other countries.

Hengfeng Machinery is known for new ideas and saving energy. It also makes high-quality products. This makes it a trusted choice for customers around the world.

International certifications like ISO and CE are very important for Chinese manufacturers. These certifications show their machines are safe and high quality.

Hengfeng works hard to keep quality high. They test their machines a lot and help customers after they buy. This helps clients get the best use from their machines.

The market for thermoforming vacuum skin packaging machines is growing fast. This is because more people need them in the food and medical industries.

China’s thermoforming machine makers are important in the world. They give advanced machines to food, drink, and stores. Some companies are old, and some are new and creative. The table below shows top companies picked by experts:

| Company Name | Description |

|---|---|

| Hengfeng Machinery Co., Ltd. | Specializes in energy-saving, automated thermoforming machines with a global service network. |

| Qisheng Machinery | Focuses on high-speed, reliable thermoforming solutions for packaging industries. |

| Jornen Machinery | Known for advanced blister packaging and thermoforming equipment. |

| Zhanshi Machinery | Offers a wide range of thermoforming machines for various applications. |

| Hualian Machinery | Delivers efficient packaging machinery with a strong domestic presence. |

| Weixin Machinery | Provides rapid-response service and innovative machine designs. |

| TZ Machinery | Supplies robust thermoforming machines for large-scale production. |

| Chengdu Rodbol Machinery Co., Ltd. | Renowned for precision and reliability in thermoforming technology. |

| GuangZhou NanYa Pulp Molding Equipment Co., Ltd. | Leads in pulp thermoforming machines with state-of-the-art technology. |

These companies are known for good machines and great service. Many send their machines to other countries. This helps China stay number one in the market.

Hengfeng is special because it cares about new ideas and quality. The company has won many awards for making customers happy and having a strong supply chain.

| Award Name | Description |

|---|---|

| Quick Response Award | Recognized for excellence in supplier services, setting a standard in the industry. |

| Stable Supply Excellence Award | Acknowledged for maintaining a stable supply chain, contributing positively to industry collaboration. |

Hengfeng has a worldwide service team to help customers fast. It sends machines to many places and works with big food and drink brands. Hengfeng uses special technology and saves energy, so people trust it.

Chinese thermoforming machine makers try to be the best by adding new features. Hengfeng is a leader because of its special strengths:

| Feature/Innovation | Description |

|---|---|

| Patented Technologies | Hengfeng possesses a number of patented technologies that enhance its machinery's performance. |

| Energy-Saving Focus | The company emphasizes energy-saving features in its thermoforming machinery. |

| Environmentally Friendly Solutions | Hengfeng's products are designed to be environmentally friendly, aligning with modern standards. |

| High Automation | The machinery is highly automated, improving efficiency in production processes. |

Hengfeng puts money into new technology to help everyone. Its machines use automation to make more products and need less work. Digital tools help watch the machines and fix problems before they stop working. Hengfeng also cares about the planet by using green materials and recycling. New heating and insulation save energy but keep the machines strong.

Other top Chinese companies, like Weixin and Hualian, answer customers quickly and deliver fast. Many have big factories and lots of repeat buyers, which means customers trust them.

Note: Chinese companies keep getting better by mixing new ideas, good quality, and quick help. Hengfeng’s wins and new ideas make it a top thermoforming machine maker.

Image Source: pexels

International certifications are very important in this market. These certifications show that Chinese companies follow strict safety and quality rules. Many buyers want to see these marks before they buy. The most common certifications are ISO and CE. These standards help companies prove their machines are safe and ready to sell in other countries.

| Certification Type | Description |

|---|---|

| CE Certification | European Conformity |

| ISO 9001 Quality Management System | International standard for quality management |

| SGS International Inspection Certificate | Certification for international inspection |

| RoHS Compliance Certificate | Compliance with restrictions on hazardous substances |

Companies with these certifications can sell in more places. These standards help companies build trust with customers. They also help the market grow by making sure products fit global needs.

Chinese thermoforming machine makers use strong quality checks and tests. They follow clear steps to keep machines safe and working well.

Go to the factory to check machines and how they are made.

Look at the company’s history and what people say about them.

Make sure every order has clear rules to follow.

Watch the whole process from start to finish.

Regular checks, like monthly machine tests and mold checks every few months, keep machines working well. Many companies use many checks and always try to get better. This helps them keep making new and improved machines.

Hengfeng is different because it cares a lot about quality and new ideas. The company uses a full quality plan that covers every step, from design to after-sales help. Hengfeng’s modern factory, new machines, and strong quality checks keep standards high.

Quality checks start with picking good materials and go through every step.

Every machine gets checked and tested before it leaves the factory.

Hengfeng gives material papers, sample products, and checks packaging carefully.

The company helps customers after they buy and gives technical help.

Hengfeng’s focus on quality and new ideas helps it work with top brands and buyers around the world. This focus keeps Hengfeng as a leader in the industry.

Chinese manufacturers sell many thermoforming vacuum skin packaging machines worldwide. They send machines to Europe, America, India, and other places. More people want these machines every year. Chinese companies make high-quality vacuum machines for different countries.

The table below shows how much money some suppliers make from exports:

| Supplier | Export Revenue (USD) |

|---|---|

| Shenzhen Weixin Plastic | $3 million |

| Zhengzhou Hento Machinery | $0 |

| Cangzhou Yi Sunda Mechanical | $1.77 million |

These numbers show Chinese companies are good at exporting. They ship lots of machines to buyers everywhere. China’s vacuum technology helps food, drink, and retail companies. Many buyers pick Chinese vacuum machines because they work well and cost less.

Chinese manufacturers want buyers to trust them. They make machines that follow world rules. Many vacuum machines from China have ISO and CE certifications. This makes buyers feel safe when they buy from China.

Hengfeng is a top exporter of thermoforming vacuum skin packaging machines. The company is known for good quality and service. Hengfeng sends its vacuum machines to many countries. Big food and drink brands use Hengfeng’s machines for cups and containers.

Hengfeng’s exports grow every year. Its vacuum machines are popular in Europe, America, and Southeast Asia. Hengfeng’s team knows what buyers need. Their machines are simple to use and easy to fix. Hengfeng’s vacuum machines help save energy and cut down on waste.

Hengfeng’s export team helps clients at every step. They help pick the right machine, install it, and train users. Hengfeng gives guides and support with every machine. Their export service helps buyers start using their new machine fast.

Note: Hengfeng succeeds by focusing on quality, service, and new ideas. Its vacuum machines fit many industries. Hengfeng’s team works hard to make sure every buyer is happy.

Chinese manufacturers know shipping and after-sales help matter to buyers. They offer many ways to get machines delivered safely and on time. Top companies give:

Help with marketing, sales, planning, and making products.

Strong checks and careful packing.

Safe storage and quick shipping for vacuum machines.

Support for buyers in Europe, America, India, and other places.

Hengfeng has a worldwide service team. They help with installation and training. Hengfeng’s after-sales help includes fast repairs and technical support. Their vacuum machines come with a warranty and easy guides. Hengfeng’s team answers questions quickly and solves problems.

Many buyers pick Hengfeng for its good shipping and after-sales help. Their machines arrive safely and work well. Hengfeng’s team makes sure every buyer can use their machine easily.

Tip: When picking a supplier, choose one with a strong service team. Good shipping and after-sales help let you get the most from your vacuum machine.

Chinese manufacturers keep getting better at exporting and shipping. They spend money on faster systems and better delivery. Their focus on vacuum technology and service helps them stay leaders in the world market for thermoforming vacuum skin packaging machines.

Image Source: pexels

Hengfeng is different because it uses special mould technology. The company makes moulds with very high accuracy. Each part of the mould is made to be almost perfect. This helps every product meet strict quality rules. Hengfeng checks every mould on real machines before sending it out. This makes sure customers get good equipment.

| Feature | Description |

|---|---|

| Precision Engineering Technology | Nanometer accuracy in each cavity, achieving ±50 nanometer accuracy even with multiple cavities. |

| Consistency in Molding Quality | 99.7% consistency across all cavities, reducing scrap rates and improving cost-effective manufacturing. |

| Quality Testing | Each mould is tested on real machines before shipment to ensure top performance. |

Hengfeng’s moulds help companies save money and protect the planet. The moulds are light and use less material. This means less waste and less pollution. Companies can pick recycled or biodegradable materials like PET and PLA. These choices help meet green rules.

Light and eco-friendly designs help the environment.

Using less material means less trash and fewer trucks.

Recycled and biodegradable materials help meet green goals.

Less waste and energy are saved with lighter packaging.

Green material choices fit different company needs.

Hengfeng’s machines also help recycle waste. Crushers break up scraps so they can be used again. This lowers harm to the earth and saves money. Special sheet technology keeps food fresh longer and cuts down on waste. These moulds are great for food and medicine companies.

Hengfeng lets companies pick moulds that fit their needs. The company makes moulds for big or small jobs and for hard shapes. The moulds are strong and can handle high heat and pressure.

| Design Factor | Description |

|---|---|

| Production Volume | Suitable for small or large quantities, especially parts with complex shapes. |

| Thermoforming Forces | Moulds withstand vacuum and pressure, depending on material and part quality. |

| Thermoforming Temperature | High thermal resistance and cooling channels improve cooling rates and product quality. |

Hengfeng’s moulds are used in many areas. Food and drink companies use them for cups and trays. Stores use them for special packaging. Other uses include cars, planes, hospitals, and offices. Hengfeng helps companies make new packaging and stay ahead in the market.

The market for thermoforming vacuum skin packaging machines in China is growing fast. The market is now worth about $350 million. Experts think it will grow by 8% each year. Many things help this market get bigger:

The food processing industry is getting bigger.

More people want packaged food.

More demand for thermoformed products means more machines are needed.

Companies make new packaging to match what people want.

Both food and medicine companies want better packaging. They buy new machines to keep food fresh and safe for longer. Stores also want good packaging because shoppers care about health and safety.

Chinese companies use new technology to make their machines better. They want to meet world standards. China’s National Technical Committee made a new rule for these machines. The rule is called "General Technical Requirements for Automatic Vacuum Skin Packaging Machine." It will start in 2026.

| Component | Description |

|---|---|

| Standard Name | General Technical Requirements for Automatic Vacuum Skin Packaging Machine |

| Approval Authority | National Technical Committee on Packaging Machinery Standardization in China |

| Effective Date | 2026 |

| Coverage | Terminology, definitions, basic parameters, performance requirements, safety, and environmental protection |

| Significance | Enhances technical strength and global recognition of Chinese enterprises in the vacuum skin packaging sector |

Companies like Hengfeng use automation and smart tools in their machines. These new features help them work faster and better. This helps them keep up with more orders.

Chinese companies have a lot of competition. They must keep up with new technology and what buyers want. New rules, like those in the European Union, say packaging must be reusable or recyclable by 2030. This means companies must make new kinds of packaging.

There are chances to grow by working with other companies and using more automation. The industry will get bigger as companies sell to new places and meet new needs. Hengfeng and other top companies spend money on research and new ideas. This helps them stay ahead and give buyers what they want.

Chinese thermoforming machine makers are number one in the world. They use new ideas and follow strict quality rules. They also sell many machines to other countries. Hengfeng is a trusted company. It gives buyers new technology and good service. People everywhere like these things.

More people want packaging that works well and is good for the earth. Companies like Hengfeng will make new trends. They will help more buyers from around the world.

Hengfeng machines are used in many industries. They help with food and drink packaging. Stores and restaurants use them too. Hospitals and clinics also use these machines. Big brands like Starbucks, McDonald’s, and KFC use them. They make cups, trays, and containers with these machines.

Hengfeng checks quality at every step. The team tests each machine before sending it out. They also test every mould. Customers get material certificates and sample products to check.

Yes, Hengfeng can make custom machines and moulds. They work with each client to meet special needs. They can make different shapes, sizes, and use special materials.

Hengfeng helps with setup and training. They also do repairs and give technical help. Their service team is worldwide and answers fast. They help customers in many countries.

Yes, Hengfeng’s machines save energy. They use new technology to use less power. This helps lower costs for making products.