Views: 0 Author: Site Editor Publish Time: 2025-11-26 Origin: Site

You want to know which thermoforming machine manufacturers are best in 2025. Picking the right company helps your business do well. The thermoforming industry is growing fast around the world. Experts think the market will be worth $1.5 billion by 2031. You can see new ideas everywhere. There are energy-saving machines and smart robots that use AI. People also use recycled thermoplastics and plastics that break down naturally. These new innovations help you make less waste and save money. They also help you create better products. To stay ahead, you need to invest in quality technology and trust reputable thermoforming machine manufacturers.

Picking a trusted thermoforming machine maker helps your business do well. The best companies give you new technology and good help.

Look at important things like market share, new tech, and service network when you choose a maker. These things help you get the best machines.

Buy machines that have automation and save energy. This lowers costs and makes things faster, so your business can earn more.

Think about being green when you pick machines. Machines that use recycled stuff and save power help you reach green goals and cut down waste.

Check after-sales help closely. Good service and fast spare parts keep your machines working well and protect your money.

Image Source: unsplash

You want to find the best thermoforming machine makers in 2025. Experts say some companies are known for new ideas and being dependable. These companies are famous for making high-quality machines. If you pick a top company, you get better technology and good help when you need it.

Here are the top thermoforming machine manufacturers for 2025:

ILLIG Maschinenbau

Kiefel Technologies

MULTIVAC

TZ Machinery

GABLER Thermoform

Brown Machine Group

MAAC Machinery

Foshan Crown Machinery

Wemac Machinery

Formech International

Brown & Company (Brown Machine)

Harland Machine Systems

Comet Plastic Equipment

FIMIC

Brown Machine (Thermoforming division)

These companies make lots of machines and use many materials. Their machines are used in factories all over the world. They help shape how thermoforming works today.

When you look at thermoforming machine makers, you should check important things. These things help you pick the company that fits your needs. The table below shows what matters most in the thermoforming market.

| Key Performance Metric | Description |

|---|---|

| Market Share | The proportion of total sales in the thermoforming machine market held by leading manufacturers. |

| Technological Advancements | Innovations in heating technologies, mold design, and automation integration. |

| Strategic Collaborations | Partnerships between equipment producers and material innovators to enhance process reliability. |

| Service Network Expansion | Development of localized technical support teams and remote monitoring for customer satisfaction. |

| Mergers and Acquisitions | Transactions to enhance product portfolios and geographic reach. |

| Aftermarket Digital Services | Introduction of remote diagnostics and software-as-a-service offerings to reshape revenue models. |

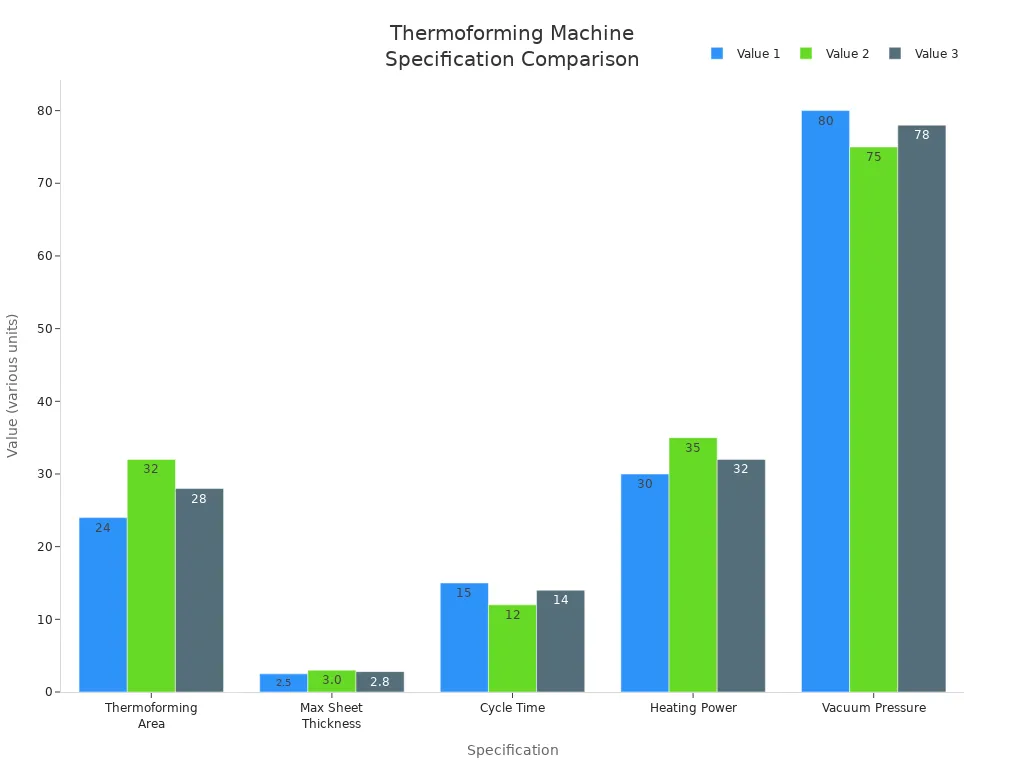

You should also look at machine details. The chart below shows how top machines compare in forming area, sheet thickness, cycle time, heating power, and vacuum pressure.

When you check these facts, you can make better choices for your business. You see which companies give you the best machines and technology. Picking the right company helps you do well in the thermoforming industry.

Picking the right thermoforming machine maker helps your business do well. You should think about a few key things before you choose. These points help you compare different brands. They help you find the best one for your needs.

You want machines with new technology. Better technology makes the process faster and more exact. Automation and robots help make more products and fewer mistakes. Many companies use smart systems to watch every step. This keeps quality high and saves money.

Note: The thermoforming industry is trying to be greener. Companies that use eco-friendly materials and save energy help you reach your green goals.

You need machines that work well all the time. Good machines do not break down often. This keeps your factory working without stops. High performance means the machine can use many materials. It can also make lots of products quickly. When machines work the same way each time, you can trust your products.

A big product range lets you pick machines for many jobs. Custom options help you get what your business needs. Some makers have machines that change between products fast. This helps you grow when the market changes.

A strong market presence means the company is trusted. Companies that sell worldwide give better help and service. You get help from local teams and quick spare parts. Famous brands often mean good quality and strong support after you buy.

Using these points helps you make better choices. You get machines that fit your needs. This helps your business do well in the thermoforming industry.

You want machines that work well and save time. Hengfeng is known for its multistation thermoforming machine. These machines use smart automation and help save energy. They also let you make different products easily. Hengfeng spends 15% of its yearly money on research and development. This helps their machines work 30% better and makes parts more exact, up to 0.05mm. Each year, they make about 50 new design changes. These changes help the machines work 15% better.

Hengfeng's newest machines use 30% less energy than older ones. Medium-sized businesses can save about $15,000 on energy each year.

The HFSJ series can process up to 800 kg every hour. This is 20% more than most other machines, so you can make more products faster.

These machines can form, cut, and stack by themselves. You can change molds quickly. Special air pressure and vacuum forming help lower your costs.

Hengfeng's multistation thermoforming machine works with many thermoplastic materials. The machines run fast and are easy to use. This means workers learn quickly and make fewer mistakes. Hengfeng's focus on being exact and efficient helps you do better in the world market.

ILLIG Maschinenbau is a leader in thermoforming technology. Their machines have special heating systems and automatic controls. These features help shape plastic evenly and make better parts. You can change molds quickly, which saves time. The machines are made to use less energy, so you spend less money running them.

| Feature | Description |

|---|---|

| Advanced heating systems | Make sure plastic is shaped evenly |

| Automated controls | Make better parts and waste less material |

| Fast mold change systems | Help workers save time during production |

| Energy-saving designs | Help companies spend less on energy |

ILLIG Maschinenbau sells machines all over the world. You can count on their help and service teams. Their machines are known for working well and lasting a long time.

GABLER Thermoform makes packaging machines that work well and last long. Their machines use the latest sensors and work with Industry 4.0. You get machines that run fast and steady. This means your factory keeps working without problems.

The Focus thermoforming machine from GABLER is flexible and fast. It uses smart movement and servo drive technology to set new records.

You can count on these machines to work well and help you make lots of packages.

GABLER Thermoform is trusted for making machines that are exact and efficient.

AVT makes advanced thermoforming centers. Their machines are built for making lots of products and for tricky shapes. AVT uses automation and smart controls. These features help you make the same good product every time and pay less for workers. AVT machines are used for things like food packaging and medical tools.

AAA Manufacturing makes custom thermoforming machines for many industries. They have over 25 years of experience. AAA can make one sample or many products. You can pick from many types of plastics and laminates.

AAA makes parts for things like boats, buses, farms, and buildings.

You can order small parts or big things like dashboards, bumpers, and panels.

Their careful heating and molding make strong and exact parts.

AAA MOULD is good at finishing orders on time. Their skilled team and fast work help them fill urgent orders and keep quality high. You get your products faster than with other companies.

Greiner Verpackungen GmbH is a leader in green thermoforming. They helped start the 'Platform Packaging with Future.' This group works to make recycling better and teach people about green packaging.

Greiner works with other companies in the packaging business.

They start projects that use green materials and help recycling.

Greiner Verpackungen GmbH helps you reach your green goals in packaging.

Kiefel GmbH makes machines that are fast and use less energy. The NATUREFORMER KFT90 model cuts cycle times by 30%. It can handle products up to 160 mm tall and press with 450 kN force.

| Feature | Description |

|---|---|

| Cycle Time Reduction | Makes each cycle 30% faster |

| Production Capabilities | Handles products up to 160 mm tall with strong pressing |

| Energy Efficiency | Uses 10 kW less energy |

| Automation Features | Stacks, boxes, and puts products on pallets automatically |

| User Interface | Easy-to-use controls for quick and simple operation |

| Applications | Makes compostable coffee lids, bowls, and plant pots |

| Moisture Control | Keeps about 7% moisture in finished products |

| Technology | Uses special Steam Flow Technology for better production |

You get machines that stack, box, and palletize by themselves. The controls are easy to use and help you switch tasks fast. Kiefel's machines make green products like compostable lids and bowls.

Brown Machine Group makes machines that work with many materials and sizes. Their machines are built in parts, so you can add them to your current lines. They run fast and work well. You can change what you make quickly when the market changes.

SencorpWhite makes machines that do forming, cutting, and stacking all together. Their machines use automation and smart controls. These features help you watch your work and keep quality the same. Their machines are used for things like medical packaging, food, and stores.

WM Thermoforming Machines are made for high accuracy. Their machines are strong and use advanced servo drive technology. They run fast and can be set up in different ways. You get good results for tough jobs.

GN Thermoforming Equipment makes machines that can handle many materials and shapes. Their controls are easy to use, and you can change molds quickly. These machines help you react fast to new market needs. GN is good for both small and big jobs.

AMUT Group puts sheet extrusion and thermoforming together. Their machines help you move materials and form products in one system. They run fast and let you control sheet thickness exactly. These systems help you waste less and use materials better.

BMB S.p.A. makes machines that work very fast. You can make lots of products quickly and use materials well. Their machines are good for big jobs and tricky shapes. BMB helps you make more products and meet tight schedules.

OMV Machinery is good at making custom thermoforming machines. You can get machines made for your special products and how much you need to make. OMV works for things like food packaging and industrial parts. Their engineers help you find the best solution.

ZED Industries makes small thermoforming machines for places with little space. Their machines work well and fit in small areas. ZED makes sure their machines are easy to use and quick to set up. You can start making products fast and keep quality high.

There are many choices for thermoforming machines. Each company has special strengths in technology, precision, and custom solutions. You can pick the best partner to help your business grow and stay ahead in the industry.

Image Source: pexels

You want machines that work well every time. Top thermoforming makers focus on speed, accuracy, and automation. The best machines make lots of products fast. They use smart sensors and controls to keep quality high. You can use different materials and sizes with multi-purpose machines. Easy controls and robot loading help workers learn quickly and make fewer mistakes. Some companies, like Kiefel, use modular systems that stack, label, and pack products by themselves. Riverside Medical Packaging uses robots and cameras to check medical packages.

| Criteria | Description |

|---|---|

| Capacity & Throughput | Fast machines are good for big orders. |

| Precision & Quality | Smart sensors and controls help make perfect products. |

| Flexibility & Versatility | Multi-purpose machines work with many materials and sizes. |

| Automation & Ease of Use | Robots and easy controls help workers and save time. |

You need machines that help you meet green goals. Top brands make machines that use less energy and work with green materials. OMV Technologies builds machines for bio-plastics. Many companies make light, recyclable products. Good heating, strong insulation, and better airflow help you save money. More machines now use recycled plastics and make less waste.

| Benchmark Type | Description |

|---|---|

| Energy Efficiency | Power-saving machines help you spend less money. |

| Sustainability | Machines work with green materials and recyclable plastics. |

Good heating systems

Strong insulation

Better airflow control

You want help after you buy your machine. Top makers give good service, fast spare parts, and help with problems. Some companies do all three, but some do not. Good support keeps your machines working and protects your money.

| Manufacturer | After-Sales Support | Spare Parts Availability | Technical Guidance |

|---|---|---|---|

| Manufacturer A | Yes | Yes | Yes |

| Manufacturer B | Yes | No | Yes |

| Manufacturer C | Yes | Yes | No |

You need to think about price and how well the machine works. Thermoplastic sheets cost 35to35to45 each, depending on the type. Molds cost 2,000to2,000to10,000, plus extra for finishing and cutting. In 2025, new tariffs made multi-station systems cost 15% more. Factories use smart plans to use less plastic and pick the best sheet sizes. Using recycled plastics and keeping machines in good shape helps you save money and work better. Machines that use green materials give you more value and help you stay ahead.

In 2025, more factories use automated systems. Automation and robots help make products faster. They also help reduce mistakes. Machines now have sensors and smart controls. These tools let you watch each step. You can change settings fast for new orders. Robots move parts and stack finished goods. This trend makes work easier and improves quality.

Tip: Automated systems help lower labor costs and increase output.

You want to reach your green goals. The thermoforming industry uses more recycled and plant-based plastics. Many machines are made to save energy. You use less power and make less waste. Some factories recycle scraps right away with closed-loop systems. These changes help the planet and save you money.

Use of recycled and plant-based plastics

Machines that use less energy

Less waste from better designs

Now you can track every part of your process with digital tools. Many machines connect to the internet. You get real-time data on speed, temperature, and quality. Data analytics help you find problems before they stop your line. You can plan repairs and avoid downtime. Digital tools help you make better choices and improve results.

| Benefit | How It Helps You |

|---|---|

| Real-time data | Solve problems faster |

| Predictive alerts | Less machine downtime |

| Easy reporting | Better planning |

Big changes are happening in where thermoforming grows fastest. Asia and South America have more new factories. Companies want to be closer to customers. There is more need for food packaging and medical products. New technology helps you keep up with these changes. You can use new machines to enter new markets and stay ahead.

Note: Watch for new rules in different countries. These rules can change how you use thermoforming and what materials you pick.

New technology, smart automation, and green practices shape the future. You can use these trends to help your business grow and face new challenges.

Picking the right thermoforming machine maker helps your business do well. You need to think about a few important things before you choose.

First, check if the machine fits your needs. Look at how big the forming area is. See how fast the machine can work. Ask what kinds of plastics the machine can use. Hengfeng’s multistation thermoforming machine works with many materials. It lets you change molds quickly. This helps you make new products or meet market changes.

Key questions to ask:

What is the biggest forming area?

How fast does the machine go?

Can it use different plastics?

Factories need automation to do better. Automation helps you make fewer mistakes and more products. Ask if the machine can connect to other machines in your factory. Hengfeng makes machines with smart automation features. These features save you time and help you make better products.

Tip: Pick machines that can join your current production line easily.

Being green is more important every year. Check if the machine uses less energy or works with recycled materials. Ask if the machine has certifications and follows local rules. Hengfeng’s machines save energy and help you make eco-friendly products. This helps you reach green goals and follow the rules.

Good after-sales support keeps your machines working well. Ask about training, spare parts, and technical help. Hengfeng gives fast help and global service. Good support means less downtime and keeps your investment safe.

You want to get the most for your money. Look at the total cost, including fixing and energy use. Compare this to how much the machine makes and how long it lasts. Hengfeng’s machines help you save money and make more profit over time.

Remember: The right thermoforming machine gives you flexibility, good quality, and saves you money for years.

You learned how the best thermoforming machine makers stack up in technology, reliability, and service. It is important to pick a machine that fits your business goals and follows new industry trends. Try to choose machines that save energy and use automation. This will help your business do well for a long time. Use this guide to help you make good choices. If you want advanced and dependable machines, think about Hengfeng’s new models for your next project.

You need to check how fast machines work. Look at the forming technology and the quality of the machines. Good after-sales support is important too. Companies with smart automation and accurate machines help you get better finishes. Reliable companies give you machines that help your business grow and work well.

Manufacturers use strong quality checks and advanced forming systems. Precision engineering helps make good products. These systems watch every step of the process. This way, you get better product quality and nice finishes every time.

Production efficiency helps you make more products and spend less money. Fast machines help you finish work on time and make more items. High-performance machines also make better products and help your business grow.

Yes, manufacturers build machines for many kinds of materials. You can use different plastics and still get accurate shapes. This helps you make many types of products and keep quality high every time.

Manufacturers spend money on research and new ideas. You get better forming technology and controls. Reliable machines help you make great products and improve your work. These things help you find new ways to grow your business.