Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

If you want great results for your business, Hengfeng’s single use plastic thermoforming machine is very good in efficiency, output quality, and ROI. Picking the right thermoforming food packages solution can make your food packaging process much better. You will get help from automation, better packaging design, and strong quality control. These things help you work faster, spend less money, and keep your products the same every time. Always check technical specs and real-world performance from trusted companies like Hengfeng before you choose.

Pick Hengfeng’s Multistation Thermoforming Machine for high efficiency. It can make up to 48 units each minute. It also saves 30% more energy than others.

Use machines with advanced temperature control and automation. This helps keep output quality the same every time. The machine can make changes right away if needed.

Buy reliable thermoforming machines to save money over time. These machines need less fixing and last over 20 years.

Choose machines that let you customize for your packaging needs. This makes your product look better and work better.

Go with companies like Hengfeng that give good customer support and training. This helps your machine run well and fixes problems fast.

When you look at plastic thermoforming machines, you want to find one that works fast and uses less energy. Hengfeng’s Multistation Thermoforming Machine is special because it has smart automation and a clever design. This machine can make up to 48 units every minute. That is quicker than most other machines. The quick-change mold system means you do not have to stop for long. The machine saves about 30% more energy. This lowers your bills and helps the planet.

Here is a table that shows how Hengfeng’s Multistation Thermoforming Machine compares to other machines:

| Feature | Hengfeng Multistation Thermoforming Machine | Competitors |

|---|---|---|

| Production Speed | Up to 48 units per minute | Slower than Hengfeng |

| Energy Efficiency | Saves up to 30% more energy | Higher energy consumption |

| Defect Rate | Less than 0.1% | Higher defect rates |

| Downtime | Minimized with quick-change mold system | Generally higher downtime |

| Safety Record | No accidents in over one million hours | N/A |

| Awards | Best in Class at the Packaging Awards | N/A |

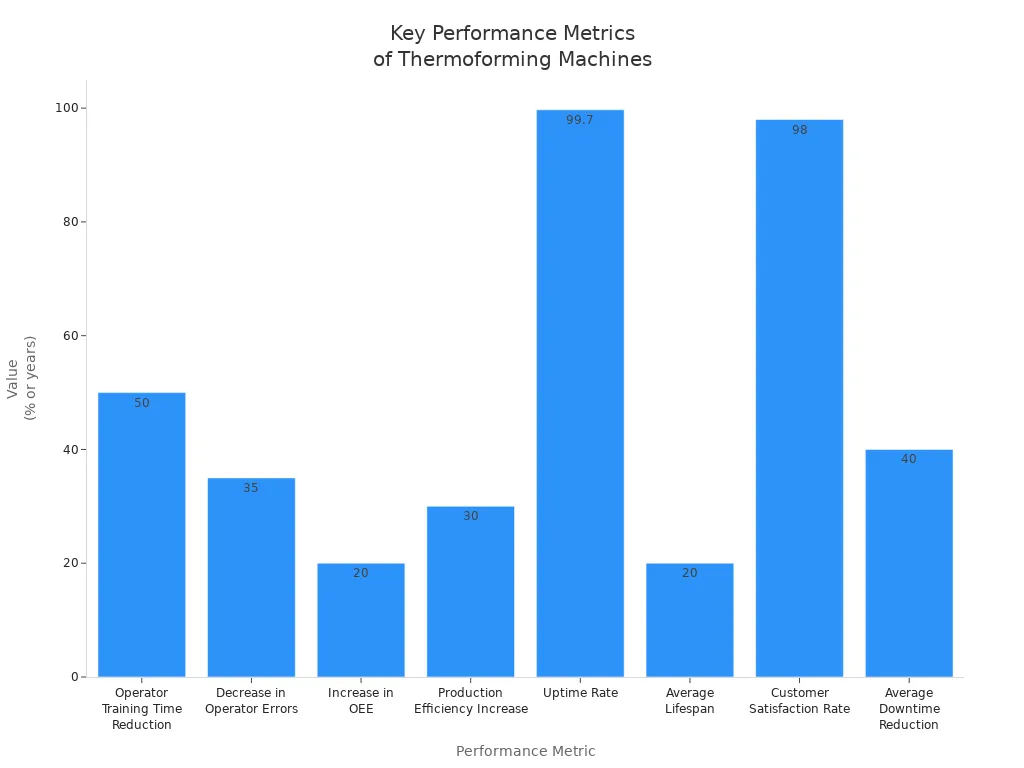

Hengfeng’s technology helps you work better and faster. Automation means workers need less training. It also means fewer mistakes. The machine works well almost all the time. You get more products made in less time. The uptime rate is 99.7%. This means the machine almost never stops.

Other advanced plastic thermoforming machines also help you save money. They have lower tooling costs and make products faster. You use over 90% of your plastic sheets, so there is less waste. These machines heat and cool quickly. This saves time and energy. You can make different shapes and change molds fast for new products.

You want your food packages to look nice and work well every time. Good output quality needs steady temperature and pressure. Hengfeng’s Multistation Thermoforming Machine uses special heating zones and cooling. This keeps the plastic even and stops problems like warping or uneven thickness.

Here are some important things that help make good quality in plastic thermoforming machines:

Advanced heating elements for even plastic softening

Proper mold design and controlled cooling

High-grade materials for strength and clarity

Automation for real-time adjustments and repeatability

Modern machines like Hengfeng’s use PLC controls to make changes right away. This helps you get the same results each time. You can add textures, logos, or special features while molding. The machine lets you make thick or thin parts as needed. Using good materials keeps your food packaging safe and clear.

A table below shows how advanced forming technologies improve your results:

| Benefit | Description |

|---|---|

| Cost-Effectiveness | Uses lower-cost molds, reducing upfront expenses. |

| Design Flexibility | Enables intricate designs, including embossed logos and functional features. |

| Fast Production | High-speed production lines minimize lead times. |

| Enhanced Food Safety | Provides airtight seals to maintain freshness and prevent contamination. |

| Material Efficiency | Reduces waste through precise material usage and compatibility with recyclable plastics. |

| Advanced Tooling and Precision | Ensures consistency and reduces material waste with modern tooling. |

| Smart Packaging | Integrates with technologies like QR codes for enhanced safety monitoring. |

| High-Barrier Films | Protects perishable items from oxygen, moisture, and UV light, enhancing shelf life. |

You want your money spent on a single use plastic thermoforming machine to be worth it. Hengfeng’s Multistation Thermoforming Machine gives you a good return because it works fast, makes few mistakes, and saves energy. The machine lasts over 20 years. Customers are happy with it 98% of the time. You spend less fixing it because it has fewer moving parts and is easy to take care of.

Here is a table that explains the main cost factors:

| Cost Factor | Description |

|---|---|

| Initial Investment | Manual machines are cheaper upfront but may cost more in labor. Fully automated machines like Hengfeng’s require more investment but pay off faster in high-volume production. |

| Maintenance Costs | Good after-sales support and easy-to-find parts keep costs low. |

| Energy Efficiency | Energy-saving features lower your bills over time. |

Picking a good machine means you do not pay a lot for repairs or downtime. You also make products faster, which lowers your cost for each item. Great machines like Hengfeng’s help your business run well for many years.

Tip: Buying a reliable, automated thermoforming machine helps you save money over time and keeps your production line working well.

When picking plastic thermoforming machines for food packaging, you should know the main types. Each type has special things that help you choose what is best for your products.

Multistation thermoforming machines have many stations that form, cut, and stack at once. This means you can make products faster and with better quality. These machines are good for making lots of food packages. Hengfeng’s Multistation Thermoforming Machine is special because it uses smart technology and automation. You can make many shapes and sizes with great accuracy. The machine keeps your work going smoothly and helps you save money.

Some cool things about multistation machines are:

Saves money by making more parts quickly.

Every product is made with good accuracy.

Can use different plastics and make hard shapes.

Lots of automation, so less manual work and fewer mistakes.

Traditional plastic thermoforming machines use manual or semi-automatic controls. These machines are usually slower and not as flexible. They are best for small batches or simple designs. If you need basic trays or containers, these machines can do that. But they may not be good for making lots of packages or fancy designs.

Here is a table that shows how different machine types compare for food packaging:

| Type of Machine | Description | Typical Applications |

|---|---|---|

| Vacuum Forming Machines | Heats a plastic sheet and uses vacuum to shape it over a mold. | Used for trays, blister packs, and clamshells. |

| Pressure Forming Machines | Uses vacuum and pressure to make strong and detailed parts. | Good for complex designs and tough food packaging. |

| Twin Sheet Thermoforming Machines | Heats and shapes two sheets at once for double walls. | Used for containers and trays that need insulation. |

Inline and specialty plastic thermoforming machines help with special food packaging needs. You can make different sizes and shapes for snacks, fruits, or meals. These machines keep food fresh and safe with strong barriers. They use thinner plastics, so there is less waste and better for the environment. Inline machines are great for fast, nonstop production lines. Specialty machines are made for certain packaging types or materials.

Tip: Advanced plastic thermoforming machines like Hengfeng’s Multistation Thermoforming Machine give you the best mix of speed, quality, and flexibility for making food packages.

Image Source: unsplash

You want your machines to work quickly. Fast machines make more products in less time. Cycle time means how long it takes to make one item. Throughput is how many items you make in a certain time. Advanced plastic thermoforming machines have shorter cycle times. They also have higher production speed. Hengfeng’s Multistation Thermoforming Machine uses automation. This helps cut down cycle time. You get more food packages every hour. Your business can grow faster. Customers will be happier with quick service.

The global thermoforming market is getting bigger. Companies that work efficiently make more products. They also spend less money.

Saving energy helps you spend less money. Using less material also lowers your costs. Hengfeng’s Multistation Thermoforming Machine uses energy-saving technology. It recycles waste heat and uses less power. The machine wastes less plastic because it cuts and forms with high precision. Three-station thermoforming machines do forming, cutting, and stacking in one cycle. This uses less energy than older machines. You help the environment and save money at the same time.

| Feature | Benefit |

|---|---|

| Energy-saving technology | Uses less power while working |

| Advanced mould design | Wastes less material and makes better products |

Automation makes machines smarter and easier to use. Hengfeng’s Multistation Thermoforming Machine has sensors and smart controls. You get alerts before something breaks. This means less downtime and fewer repairs. Siemens found sensors can lower maintenance costs by 25%. AI-powered systems watch your machines and warn you early. You keep your production running and avoid big problems.

Predictive maintenance helps you save up to 40% on costs. It also cuts downtime by half. You make more products and spend less fixing machines.

Automation makes cycle times shorter and checks products better.

Monitoring all the time finds problems before they stop your work.

Real-time data helps you keep machines working well.

You get better results with a single use plastic thermoforming machine that has strong automation and smart maintenance. Hengfeng’s machine gives you high efficiency, fast production, and less waste. You can trust it to keep your food packaging business running smoothly.

You want each package to look the same. Packages should work well every time. Consistency and precision are important for food packages. Mold design, materials, and machine controls affect quality. Hengfeng’s machine uses servo motors and fast mold changes. These features help keep packages the same size and shape. You get fewer mistakes and better results.

Here is a table that shows what helps you get consistent and precise packages:

| Factor | Description |

|---|---|

| Mold Design | Deep cavities or tricky shapes need more stretching, which can make some areas thinner. |

| Material Properties | Different plastics stretch in different ways, so thickness can change. |

| Process Parameters | Temperature, heating time, and pressure settings decide how evenly the plastic stretches. |

| Forming Methods | Vacuum forming and pressure forming change how smooth and even the package turns out. |

You need to choose the right plastic for your food packages. Hengfeng’s machines work with many kinds of plastics. PET is strong and clear. PS is light and cheap. PP is good for microwave use. PLA and bio-based plastics help the environment. Multi-layer materials protect sensitive food.

| Material Type | Description | Impact on Packaging Solutions |

|---|---|---|

| PET | Strong and clear plastic. | Good for many food products and keeps them safe. |

| PS | Lightweight and low cost. | Best for disposable packages. |

| PP | Handles heat and chemicals. | Works for microwaveable packages. |

| PLA | Made from plants and breaks down easily. | Helps you meet green goals. |

| Multi-layer | Mixes different plastics for better results. | Keeps food fresh longer. |

| Bio-based | Comes from natural sources. | Good for eco-friendly packages. |

Smart machines help you get better quality. Hengfeng’s machines use automation to work faster and more accurately. The automatic cutting bed saves material and boosts output. Welding robots make strong joins and work quickly. The intelligent hanger system lowers waste and makes production smoother.

Automation helps you make more packages with fewer mistakes.

Automatic cutting beds save material and speed up work.

Welding robots make joins stronger and improve quality.

Intelligent hanger systems lower waste and raise efficiency.

You get high-quality food packages every time with advanced forming technologies. Hengfeng’s machines help you reach your goals for quality, speed, and reliability in thermoforming.

Image Source: pexels

When you pick a plastic thermoforming machine, you want to know how much money you spend first and how much you save later. Thermoforming machines usually cost less at the start than other ways to make things. You also pay less for tooling. Hengfeng’s Multistation Thermoforming Machine uses smart systems that help you save energy and work faster. This means your business can save more money.

Here is a table that shows how thermoforming machines and other methods compare:

| Factor | Thermoforming Machines | Other Manufacturing Methods |

|---|---|---|

| Initial Investment | Lower | Higher |

| Tooling Costs | 50-70% lower | Higher |

| Production Speed | High | Varies |

| Flexibility | Better for small runs | Limited |

| Energy Efficiency | Advanced systems | Varies |

You can see that thermoforming machines help you save money right away. They also make products faster and let you change designs easily. Hengfeng’s machine uses less energy, so your bills are lower. You get more products for every dollar you spend.

Tip: If you want to make food packages fast and keep costs down, a thermoforming machine is a good choice.

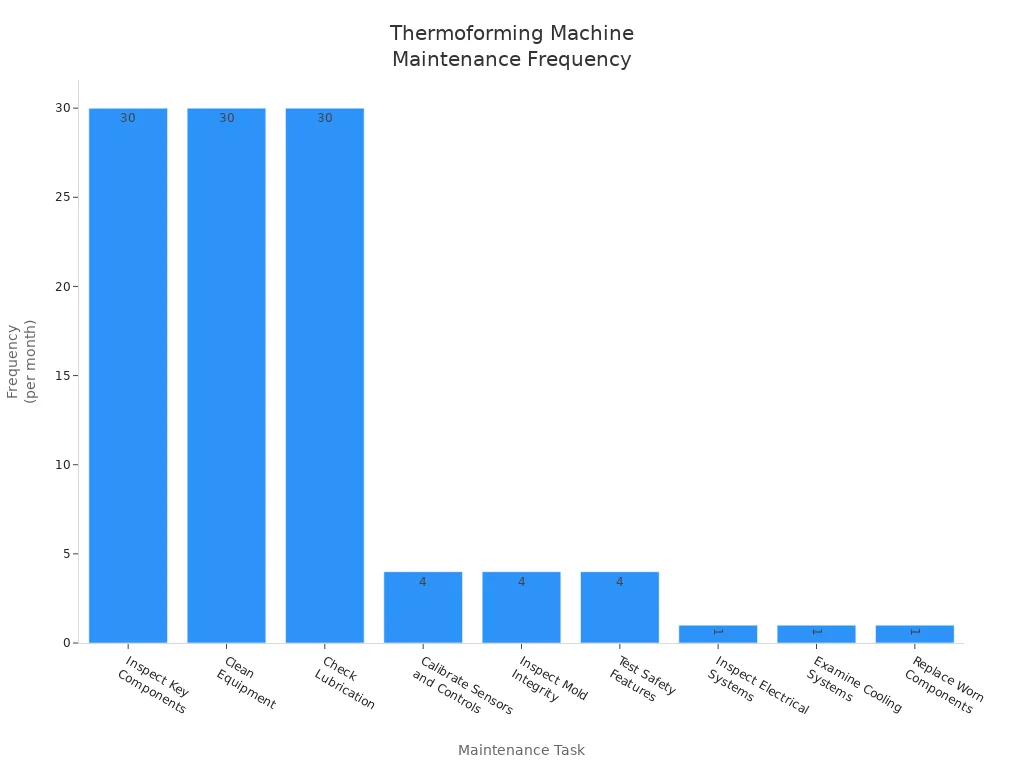

Taking care of your machine helps you save money and makes it last longer. Regular maintenance lets you find small problems before they get worse. Hengfeng’s Multistation Thermoforming Machine is easy to take care of. You can check parts, clean the machine, and change old pieces without much trouble. This helps you save money and use your machine for more years.

You should do these things to keep your machine working well:

Visual Inspection: Look for broken or loose parts and anything strange.

Cleaning Procedures: Clean around the machine every day to stop dust and dirt from building up.

Here is a table that shows how often you should do each maintenance job:

| Maintenance Task | Frequency |

|---|---|

| Inspect Key Components | Daily |

| Clean Equipment | Daily |

| Check Lubrication | Daily |

| Calibrate Sensors/Controls | Weekly |

| Inspect Mold Integrity | Weekly |

| Test Safety Features | Weekly |

| Inspect Electrical Systems | Monthly |

| Examine Cooling Systems | Monthly |

| Replace Worn Components | Monthly |

You should also:

Follow the maker’s rules.

Write down what you do for maintenance.

Teach workers how to care for the machine.

Use good parts.

Hengfeng’s machine can last over 20 years if you take care of it. You spend less fixing it and have fewer stops. This helps you get more for your money.

You want to know how much money you make with your machine. Hengfeng’s Multistation Thermoforming Machine helps you earn more profit. You get fast production, fewer mistakes, and strong cost savings. Automated features mean you need fewer workers and make fewer errors. Energy-saving systems lower your bills. You spend less on materials because the machine uses plastic sheets very well.

Here are some important things to watch:

Production speed: More products made every hour.

Defect rate: Fewer mistakes mean less waste.

Energy use: Lower bills help you save money.

Maintenance costs: Easy care keeps costs low.

Lifespan: Machines that last longer give you better value.

Note: If you pick a machine with smart automation and energy-saving features, you save more money and make higher profits. Hengfeng’s Multistation Thermoforming Machine helps your business grow and keeps your food packaging line working well.

You can see Hengfeng’s Multistation Thermoforming Machine in action at busy factories. These machines help you make thousands of packages every hour. You get fast cycle times and steady output. Many companies use Hengfeng’s machines to pack snacks, drinks, and ready meals. You can trust the machine to keep up with high demand. The machine forms, cuts, and stacks packages without stopping. This helps you deliver fresh food to stores quickly.

Tip: If you want to boost your production, choose a machine that works fast and keeps quality high.

You might know brands like Starbucks, McDonald’s, and Luckin Coffee. These companies use Hengfeng’s machines to make custom cups and containers. Hengfeng listens to what you need. You get machines that fit your brand’s style and size. The team helps you design molds for special shapes or logos. You can change molds quickly to launch new products. Hengfeng’s engineers work with you to solve problems and improve your packaging.

| Brand | Product Type | Custom Feature |

|---|---|---|

| Starbucks | Drink Cups | Embossed Logo |

| McDonald’s | Food Containers | Special Shapes |

| Luckin Coffee | Beverage Cups | Fast Mold Change |

You get help from Hengfeng no matter where you are. The company has a global service network. You can call for support or order spare parts. Hengfeng’s team trains your workers and helps you set up machines. If you have a problem, you get quick answers. The company sends experts to your site if needed. You keep your machines running and avoid long stops.

Note: Good service means you spend less time fixing problems and more time making products.

You should think about a few big things before picking a plastic thermoforming machine. First, decide what products you want to make. Next, choose which plastics work best for your items. Make sure the machine can heat, shape, and cut your materials. Automation helps you work faster and make fewer mistakes. Cost is important too. You want a machine that saves money in the long run. Pick a company that gives good help and stands by their machines.

Here is a table to help you compare the most important things:

| Criteria | Description |

|---|---|

| Production Requirements | Think about the products and plastics you need. |

| Machine Features | Look at heating, shaping, cutting, and automation. |

| Cost Considerations | Check the price and how much you can save later. |

| Manufacturer Reputation | Pick a company with good support and trust. |

Hengfeng’s machines have strong automation, fast mold changes, and work with many plastics. Their team helps you when you need it.

You do not want to make mistakes when buying a thermoforming machine. Some people forget to check if the machine fits in their space. Others do not ask about help after buying. If the machine cannot make enough products, you might lose money. Always ask about fixing and spare parts. Make sure the machine works with the plastics you use for food packaging.

Tip: Ask to see the machine in action or visit a factory before you buy. This lets you see how it works in real life.

Use this checklist to help you pick the best machine:

Write down the products you want to make.

Make sure the machine works with your plastics.

Ask about how fast and automatic it is.

Find out how long mold changes take.

Look at the warranty and help services.

Check if the machine fits in your space.

Ask about training for your workers.

Make sure the machine is safe to use.

Compare how much it costs now and later.

Hengfeng can make machines just for you. Their team helps you set up, train your workers, and keep your machine working well.

You need a machine that is quick and saves money. It should make strong packages every time. Hengfeng’s Multistation Thermoforming Machine is known for working well. It gives you good quality and helps you spend less. Many companies pick Hengfeng for food packaging. The table below shows why businesses like Hengfeng:

| Feature/Benefit | Description |

|---|---|

| Customization capabilities | Machines match your needs and can change easily. |

| Innovative features | Smart systems keep work steady and safe. |

| Energy efficiency | You use less power and make more packages. |

| Strong customer support | Hengfeng helps you fix problems and grow fast. |

You can talk to Hengfeng for special help and custom machines. Their support helps your business do well.

You can use many plastics with this machine. It works with PP, PS, PET, PLA, and bio-based materials. This lets you make different food packages for many needs.

Check and clean your machine every day to keep it working well. Look at important parts once a week. Change old or broken pieces every month. Taking care of your machine helps it last longer.

Yes, you can ask for custom molds, heating, or sizes. Hengfeng’s team will help you get the right fit for your packaging.

You get help setting up your machine and learning how to use it. The team helps fix problems fast and sends spare parts quickly. Hengfeng’s service team is ready to help you anywhere.