Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

You notice how a customized disposable thermoforming machine works when you grab a food tray with a special shape or a medical device package that looks different. Companies use these machines to make products that fit certain needs. The worldwide market for thermoforming machines was [1.8billion](https://dataintelo.com/report/thermoforming−machines−market)in2023.Itmayreach1.8billion](https://dataintelo.com/report/thermoforming−machines−market)in2023.Itmayreach2.7 billion by 2032. This growth happens because of new technology and people wanting eco-friendly packaging. Customization lets you make cool shapes and nice-looking packages. This helps products get noticed and match what buyers want.

Customized disposable thermoforming machines make special shapes and designs. This helps products look different from others in stores.

These machines help make things faster by using automation. They also use less material and save energy.

You can change the design easily by switching molds. This helps you meet what customers want and follow new trends.

Picking the best machine means looking at what materials work with it. You should also think about how much you need to make and if the maker gives good help.

Buying customized thermoforming machines can save money over time. It can also make your products better and help your business grow.

A customized disposable thermoforming machine helps you make packaging and products in new ways. The machine uses heat and pressure to shape plastic sheets. You can pick a custom mold for each product. This means you get the size and shape you want. The machine works quickly and uses less plastic. This saves money and helps the planet.

Tip: Using a customized disposable thermoforming machine makes your work faster and cuts down on waste.

Here is a table that shows some important benefits you get when you use this machine:

| Benefit | Description |

|---|---|

| Increased Production Efficiency | Full automation makes work easier and faster. You need fewer workers and make more products. |

| Reduced Material Waste | Hollow shapes use less plastic and make less trash. This is better for the environment. |

| Energy Efficiency | Special heating and cooling systems use less energy and cost less money. |

Manufacturers say that switching to a customized disposable thermoforming machine helps them heat plastic faster and make fewer mistakes. For example, FastForm Plastics used a new heating system and made 30% more products. UniformHeat Technologies lowered their mistakes by 40% with a better heating system. These examples show that the right machine and mold can help a lot.

You can make almost any shape you want with a customized disposable thermoforming machine. The process lets you use a custom mold for each product. You can make special curves, angles, and sizes. You can change the mold if you want a new design. This helps you keep up with new trends and what customers want.

You can make shapes and curves that other machines cannot do.

You can change the mold without spending much money.

You can design things for many jobs, like food or medical supplies.

You can use different plastics and change the mold for each one.

You can make parts that fit together well, so building is easier and better.

A customized disposable thermoforming machine uses plastic sheets that are already made. This way is good for making big parts and finishing jobs fast. You can use a custom mold to match your brand or meet special needs. The machine helps the environment because you can recycle extra plastic and make less trash.

Note: The biggest trends are helping the planet, making more custom designs, and using new technology like digital prototyping and automation.

You can use a customized disposable thermoforming machine to make many products. Each product uses a custom mold for the right shape and size. Here are some common examples:

| Product Type | Typical Applications |

|---|---|

| Food and beverage packaging | Clamshells, blister packs, plastic pallets |

| Point of purchase displays | Product stands |

| Signage | Internal and external signs |

| Food Packaging Trays | Single-use trays, clamshell containers |

| Medical waste containers | Used in healthcare settings |

You see these products all the time. Food trays and clamshell containers keep food safe and fresh. Medical waste containers help hospitals handle trash. Product stands and signs help stores show things and give information. Each product starts with a custom mold, so you get the best fit and look.

Callout: When you pick a customized disposable thermoforming machine, you can make products that look special and meet tough rules.

You can see how custom molds and flexible designs help you make disposable products for many uses. The machine lets you control the process, so your products match your brand and what your customers want.

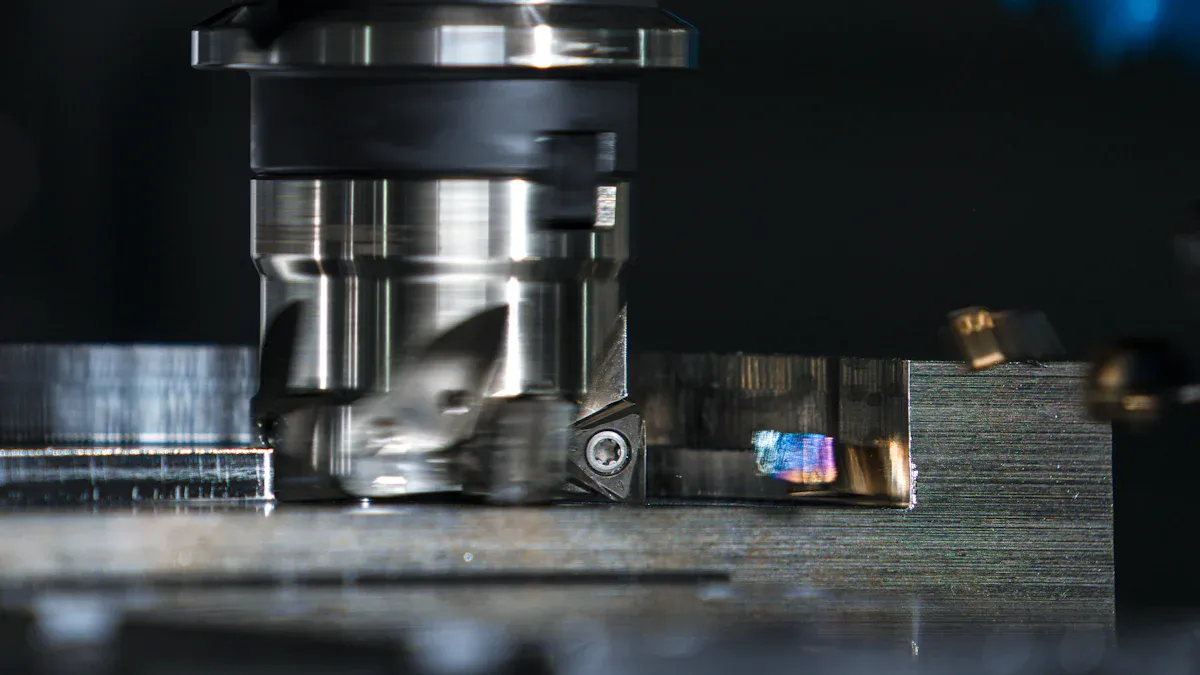

Image Source: pexels

A modern thermoforming machine has many important parts. Each part helps make good disposable products. The feeding system moves plastic sheets quickly and smoothly. The heating unit warms the plastic to the right temperature. The forming station shapes each product with care. The trimming station cuts off extra material for a neat finish. The stacking system puts finished items in order for easy handling.

You also get help from mold systems that are very precise. Vacuum forming and cooling systems make products strong and smooth. Automatic waste recycling helps keep things clean. Smart temperature controls keep the plastic just right every time.

| Component | Contribution to Performance |

|---|---|

| Feeding System | Supplies plastic sheets quickly and smoothly. |

| Heating Unit | Heats the plastic to the right temperature for forming. |

| Forming Station | Shapes the product with accuracy and consistency. |

| Trimming Station | Cuts away extra material for a clean finish. |

| Stacking System | Organizes finished items for easy handling. |

The thermoforming process uses heat, pressure, and molds. These steps help shape plastic sheets into products. First, you put the plastic sheet into clamping frames. Next, you heat the plastic until it gets soft. Then, you push the soft plastic into the mold. Vacuum forming shapes the plastic to fit the mold. After that, the part cools and gets hard. You check the quality and trim the edges. Last, you smooth the edges for a nice finish.

This process lets you make many shapes and sizes. You control each step to meet strict rules.

Insert plastic sheeting into clamping frames.

Heat the plastic sheeting until it becomes soft.

Push the sheeting into the mold.

Use vacuum forming to shape the plastic to the mold.

Let the part cool and harden.

Check quality and trim the edges.

Refine the edges for a smooth finish.

New technology makes thermoforming machines work better and greener. You can use recycled and biodegradable plastics to cut down on waste. Automation and robots help you work faster and make fewer mistakes. Digital controls let you watch the machine and fix problems early.

Energy-saving systems like heat pumps and smart heaters use less power. Recycling systems let you reuse leftover plastic and make less trash. Making smaller products uses less material and energy. Stores that use eco-friendly materials help protect nature.

Tip: A three-station thermoforming machine does forming, cutting, and stacking all at once. This saves energy and makes less waste than old machines.

Better machines and new processes help you make great products. They also save resources and help the planet.

Image Source: unsplash

You find thermoformed food packaging in stores and restaurants. This packaging keeps food fresh and safe. It is used for vegetables, fruits, seafood, and grains. Thermoformed packaging seals tightly and protects food well. It helps food last longer and look better on shelves. The packaging is easy to open and use. Many companies pick this packaging because it saves money and works fast. You can change the shape and size for each food. This helps you follow safety rules and keep food clean.

Here is a table that shows how thermoformed food packaging helps different foods:

| Food Products | Benefits of Thermoformed Packaging |

|---|---|

| Vegetables | Longer shelf life, better looks, strong packaging |

| Fruits | Tight seal for freshness, looks nice |

| Seafood | Stops damage, keeps seafood fresh |

| Grains | Strong packaging, longer shelf life |

You get many choices with this packaging. You can make trays, clamshells, and containers for all needs. Using less plastic helps the planet. You can also recycle this packaging.

Thermoforming machines make medical trays, blister packs, and waste containers. These products keep medical tools clean and safe. The packaging is light and strong. It meets health rules. You can design packaging for each medical item. This protects patients and workers. Single-use packaging stops germs from spreading.

Thermoforming machines make car parts and industrial trays. These parts are light and strong. They help cars work better. You save money because tools cost less and work is fast. You can make big and complex shapes for machines. This helps cars use less fuel and last longer. The parts fit together well and work with robots.

Here is a table that shows why different industries use these machines:

| Industry | Primary Reasons for Adoption |

|---|---|

| Automotive | Low tool cost, flexible design, saves material |

| Medical | Light, strong, meets safety rules |

| Consumer Goods | Easy to change design, quick samples |

| Packaging | Fast and saves money |

You see thermoformed packaging for many products. It is used for electronics, toys, and home items. You can change designs fast to follow trends. The packaging is light and can be recycled. It keeps products safe and fresh. People want packaging that is easy to use and good for nature. More people want special packaging just for them. Companies use new machines to make packaging faster and better. Thermoformed packaging helps meet what the market wants.

Tip: Thermoformed packaging helps your products stand out and keeps them safe and fresh.

When you pick thermoforming equipment, you must think about many things. These things help you get good results and stop problems. You should learn about the materials, machine features, how much you want to make, help from the company, and cost.

You need to know what materials you want to use first. Each material acts in a different way. Some plastics need more heat. Others cool down fast or fight off chemicals. You must check if your machine can work with the materials you pick.

| Material Type | Properties and Applications |

|---|---|

| Polystyrene (PS) | Clear and affordable; used for packaging and disposable tableware. |

| Polyethylene (PE) | Flexible and lightweight; used in packaging and automotive parts. |

| Polypropylene (PP) | Good chemical resistance; used for packaging and medical devices. |

| Polycarbonate (PC) | Clear and strong; used for automotive headlights. |

| ABS | Tough and versatile; used for automotive interiors. |

You should know the melt temperature and how long it takes to cool. Your machine must match these needs. If you use the wrong settings, you may waste plastic or get bad products. Always check if your machine works with the plastics you want to use.

Tip: Test your materials with the machine before making a lot.

You want a machine that helps you work fast and make good products. Look for machines with good heating, smart controls, and automation. These things help you work better and make fewer mistakes. Some machines let you change molds for new shapes.

| Feature | Description |

|---|---|

| Production Volume | Pick a machine that matches your output needs. Manual and semi-automatic for small jobs, fully automatic for big jobs. |

| Material Compatibility | Make sure the machine can process your chosen plastics. |

| Machine Features | Look for automation, heating systems, and control panels for better results. |

| Customization Capabilities | Choose machines that let you create special shapes and sizes. |

| Cost and ROI | Compare upfront costs with long-term savings. |

| Supplier Support | Pick suppliers that offer training and help when you need it. |

Check if the machine has safety features and is easy to fix. Digital controls help you watch your work and fix problems fast.

How much you want to make changes what machine you need. Think about how many products you want and how fast you need them. Cycle time is very important. Shorter cycle times mean you make more and save money.

Cycle time tells you how fast you make each product.

Faster cycle times help you make more and earn more.

Material, sheet thickness, heating, cooling, and machine design all change cycle time.

Only use mold cooling time for small jobs or tests.

The right tools help you save money and work well.

Match your goals with what the machine can do. If you need to make a lot, pick a fully automatic machine. For small jobs or tests, manual or semi-automatic machines may be better.

Good help from the company is important for your machine. You need help to set up, learn, and fix your machine. Good support keeps your machine working and stops long breaks.

On-site help lets you set up your machine the right way.

After-sales help gives you repairs and spare parts.

24/7 support helps you fix problems any time.

Training helps you work safely and better.

Ask the company about their help before you buy. Good support means fewer problems and better work.

Cost is a big thing when you pick a machine. You must look at the price and how much you can save later. Fully automatic machines cost more but make more and need less work from people.

| Machine Type | Cost Range | Output Capacity |

|---|---|---|

| Manual Thermoforming | 3,000–3,000–8,000 | 100–300 cups/hour |

| Semi-Automatic | 8,000–8,000–20,000 | 600–1,500 cups/hour |

| Fully Automatic | 20,000–20,000–80,000+ | 2,000–6,000+ cups/hour |

Think about how much you save on work, plastic, and energy. Customization helps you make products that fit your needs and look special. This can help you earn more and grow your business.

Note: Custom packaging costs more at first, but it can help you get more customers and waste less.

You may have problems like heating, mold, or material feed issues. You can fix these by keeping your machine clean and using good materials. Check your machine often and train your workers to stop most problems.

| Challenge | Solution |

|---|---|

| Heating inconsistencies | Optimize process parameters and ensure proper temperature control. |

| Mold defects | Increase mold temperature and ensure molds are made to standard specifications. |

| Vacuum system failures | Conduct regular maintenance and check for blockages in the vacuum system. |

| Material feed issues | Ensure uniformity in raw material quality and thickness. |

| Cooling problems | Design an effective cooling system and check for proper water flow. |

| Uneven thickness | Control temperature and ensure uniformity in raw materials. |

| Scratches or hairline problems | Implement preventive measures during production to avoid material overcooking. |

| Burst problems | Adjust raw material formulation and monitor environmental conditions during production. |

| Water ripples | Use qualified materials and optimize processing techniques to minimize surface defects. |

| Mold damage | Control temperature and pressure during the thermoforming process to prevent damage. |

| Color difference | Use uniformly colored materials and control heating temperatures to avoid inconsistencies. |

You can stop most problems by picking the right machine and working with a good company. When you follow these steps, you get a machine that works well and helps your business do better.

You get lots of benefits with customized disposable thermoforming machines. These machines help save money and give you more design choices. They work with many kinds of plastics. You can make sure your products are always good quality.

| Advantage | Description |

|---|---|

| Cost-effectiveness | You spend less on tools for big jobs. |

| Design flexibility | You can make big parts and cool shapes. |

| Material versatility | The machine works with lots of plastics. |

| Quality control | You get the same good results every time. |

Pick machine features and materials that fit your business needs. Think about who will buy your products and how much you want to spend. If you want better products, talk to experts and train your team.

Ask specialists to help set up your machine.

Use special services to make your machine work better.

Teach your workers how to use the machine the right way.

Tip: Picking carefully and getting expert help lets you get the most from your machine.

These machines work with lots of plastics. Some common ones are polystyrene, polyethylene, polypropylene, and ABS. Each plastic is good for different products. Always make sure your machine fits the plastic you pick.

Clean your machines often and look for broken parts. Doing regular checks helps your machines last longer. Use good plastic and follow the machine instructions. This keeps your machines working well and stops problems.

Yes, you can recycle extra plastic from these machines. Many machines have recycling systems built in. You collect leftover plastic and send it to recycling. This saves money and helps the environment.

Wear safety gear when you use these machines. Keep your hands away from hot plastic and moving parts. Always follow safety rules for your machines. Training helps you stay safe and avoid accidents.

Think about what plastic you want to use. Check the size of your products and how many you need. Pick machines that match your goals. Ask experts about machine features and help before you buy.