Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

You need new technology and smart machines to make great water cups. Thermoforming machines with special designs help you work faster and get the same good results each time. The market for thermoforming is growing quickly. Machines that can run 10 to 20 moulds each minute will be used for 42% of the world’s needs by 2025. Hengfeng is a leader in this change. They focus on making things better and always improving. These changes help you make strong cups that always meet tough rules.

Advanced heating systems help cups stay the same quality. Use electric heating or heat pump systems to save energy. These systems also help lower costs.

Precision molding and pressure control make cups strong and even. Change pressure and speed to stop defects. This helps keep cups good quality.

Fast cooling and trimming make production quicker. Use water-cooled aluminum tools for better cups. Trim-in-place technology also helps cup quality.

Smart automation keeps things clean and steady. Use sensors and cameras to check quality. They help find defects early.

Pick the right thermoforming machine for your needs. Think about cup size and material compatibility. Also look at energy efficiency for best results.

Image Source: unsplash

You need a good heating system to make strong cups. Plastic cup thermoforming machines use different ways to heat up. The most common way is electric heating. It gives steady heat that you can trust. Some machines use heat pump systems or energy storage. These help save power and lower costs. You can see the main heating ways in the table below:

| Heating Method | Description |

|---|---|

| Electric | Common method used in thermoforming machines |

| Strategy | Description | Impact on Energy Efficiency |

|---|---|---|

| Heat Pump Systems | Reuse heat and save up to half the energy. | Big energy savings |

| Energy Storage Technologies | Save heat for later, use less energy. | Less energy used |

| Optimizing Heating Systems | Use better heaters and smart controls. | Less energy used |

Modern plastic cup thermoforming machines, like Hengfeng’s Tilting Cup Making Machines, watch the heating zone all the time. This keeps the temperature just right. It helps you get cups that look the same every time. PID control algorithms help set the best temperature. This stops problems like cracks or cups with uneven shapes. Using advanced heating gives you better cups and saves energy too.

Tip: Even small changes in temperature or pressure can change your cup. Always check your settings before you start making new cups.

You want every cup to look the same and be strong. Precision molding helps make this happen. Plastic cup thermoforming machines use CNC-finished molds. These molds make sure each cup has the right size and smooth sides. You can make simple or fancy cup designs with these molds. The table below shows some important molding ways:

| Precision Molding Technique | Description |

|---|---|

| Precision Mold Forming | Advanced technique ensuring high accuracy in molding |

| CNC-finished molds | Molds designed with computer numerical control for precise dimensions |

| Complex cup designs | Capability to create intricate designs with uniform wall thickness |

Pressure control is also very important. Too much pressure can leave marks or lines on cups. Too little pressure means the cup might not form all the way. The best machines let you change the pressure and speed for each job. Hengfeng’s Tilting Cup Making Machines use a 7-bar air pressure system. This helps stop problems like flash, sink marks, or spray marks. You get cups that are always strong and look good.

Good pressure control stops problems like flash, short shots, and sink marks.

Balancing pressure and speed helps fill the mold and keeps the cup strong.

Controlling speed and pressure is important to stop defects in the cups.

After making the cup, you need to cool it fast. Plastic cup thermoforming machines use water-cooled aluminum tools. These cool the cup much faster than old tools. Aluminum molds help move heat away quickly. This means you can make more cups in less time.

Trimming is the last step. Good trimming gives you cups with smooth edges and the right weight. Hengfeng’s cup thermoforming machine uses trim-in-place technology. This means the machine forms and cuts the cup at the same time. You get cups that fit well and are strong. The table below shows why good trimming is important:

| Benefit | Description |

|---|---|

| Precision | Forming and cutting occur in a single step, leading to extremely precise production. |

| Material Efficiency | Lower material input due to optimal distribution of material. |

| Product Quality | Cups are precisely shaped, extremely stable, and have better top-loading stability. |

| Weight Reduction | TIP cups weigh less (3 grams instead of 4 grams) while maintaining quality. |

Cups made with trim-in-place technology are:

Shaped just right

Very stable

A perfect fit

Have the best top strength

Hengfeng’s Tilting Cup Making Machines are special because they use smart technology and real-time checks. You get more cups, fewer mistakes, and use less energy. These features help you make great cups every time.

Cup thermoforming technology helps you make plastic cups fast. First, a plastic sheet gets heated up. A PLC programmable controller keeps the heat even. When the sheet is hot enough, it goes into molds. The molds shape the sheet into cups. You can make cups in many shapes and sizes. After shaping, special systems cool the cups down. Cooling makes the cups strong and helps them keep their shape.

Shape the cup using accurate molds.

Cool and take out the finished cup.

Thermoforming machines give you many good things. The table below shows why thermoforming is better than other ways.

| Advantage | Description |

|---|---|

| Versatility | You can make many shapes and sizes for different industries. |

| Cost-effective | You need less tooling and equipment, so you produce more cups at lower cost. |

| Material flexibility | You use different thermoplastic materials for special needs. |

| Customization | You choose colors, finishes, and textures for your product. |

| Sustainability | You create less waste, which helps the environment. |

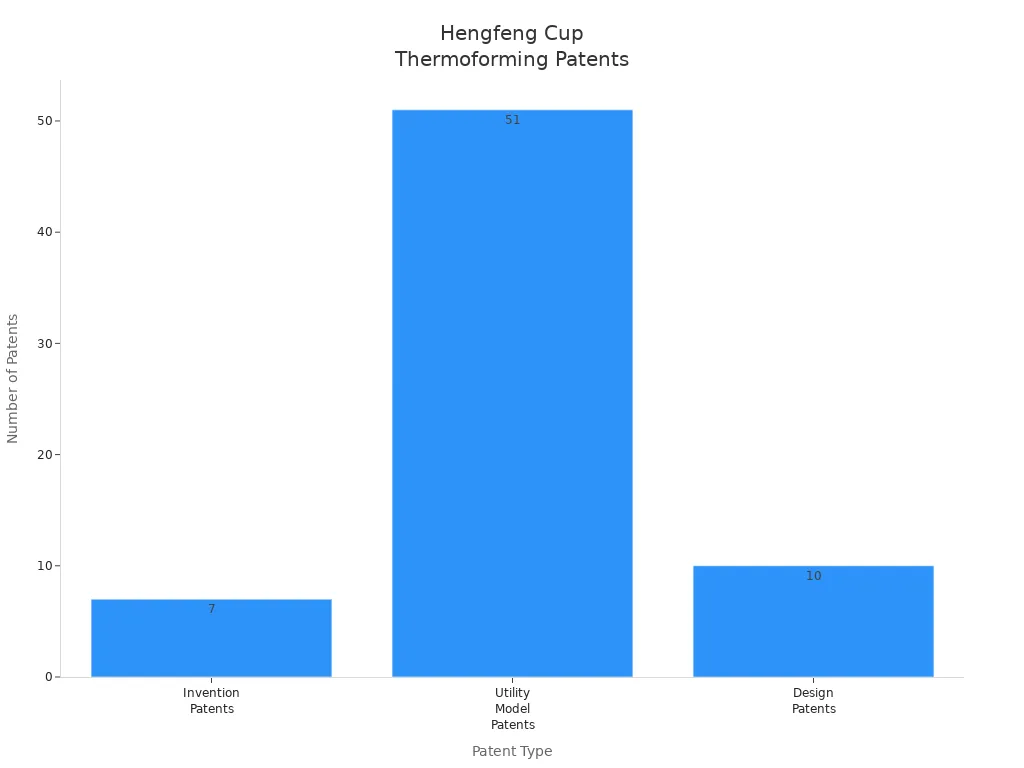

Hengfeng is a top company in cup thermoforming technology. They have many patents for their machines and designs. The chart below shows Hengfeng’s invention, utility model, and design patents.

You want your cups to be safe and clean. Automation in thermoforming machines helps you reach high hygiene standards. Machines use sensors and smart cameras to check each cup. This helps you find problems early and keep your cups looking the same.

"This requirement was especially visible during the pandemic in recent years," said Mehmed Handanagic, sales manager for automation with Kiefel Technologies.

Smart systems check product quality in new ways.

Sensors and cameras help you find defects before customers get the cups.

Cup thermoforming technology gives you better control over making cups. You can meet strict hygiene rules. Hengfeng’s special ideas help you stay ahead in the industry.

Image Source: unsplash

You want to use all your material wisely. Thermoforming machines help with this. They use sensors and smart controls. These machines check the material as you work. If something changes, they fix it right away. This means you waste less plastic. You also get fewer bad cups. Using recyclable or biodegradable materials helps the planet. It also makes your cups better. Good quality control finds problems early. You throw away fewer cups and save money. Hengfeng’s thermoforming machines use these smart tools. You get better results and less waste every time.

Modern thermoforming machines use smart control systems. These systems help you work faster. You get real-time data from the machine. This lets you check quality at every step. You can see how the machine works. You can fix problems quickly. These systems keep records of each run. You can measure how well you do. You can make changes if needed. Smart controls help you save money. You use less material and make fewer mistakes. You get more good cups and less scrap. This keeps your product quality high.

Real-time data helps you check quality often. It keeps your machine running longer.

Process records help you follow the same steps. Your cups stay the same.

Smart systems lower costs. They reduce scrap and help you earn more.

You need to change molds fast for new orders. Quick-change mold design saves you time. You can switch molds faster than before. This means less waiting and more cups made each day. Automation cuts down on manual work. You make fewer mistakes and work safer. Quick-change molds give you more choices. You can make different cup shapes and sizes. You do not have to wait long. This helps you meet market needs. It also makes your production better.

Quick-change molds cut downtime and speed up work.

Automation lowers mistakes and keeps your team safe.

Flexible mold systems let you make new cup designs fast.

You must pick a machine that fits your goals. First, think about the cup sizes and shapes you want. Some machines make small cups. Others can make big cups. Check what materials you will use, like PET, PP, or PLA. Hengfeng’s Tilting Cup Making Machines work with many materials. They even support eco-friendly choices. This helps if you care about the environment.

Think about how fast you need to make cups. If you have big orders, speed is important. Automation can help you work faster and save money on workers. Energy efficiency is also important. It can lower your costs over time. The table below lists important parts to check before buying a machine:

| Criteria | Description |

|---|---|

| Cup Size and Shape | Fits your specific cup needs, from small to large. |

| Material Compatibility | Works with plastics like PET, PP, and biodegradable materials. |

| Automation Level | Choose manual, semi-automated, or fully automated for your needs. |

| Energy Efficiency | Uses less power for lower costs. |

| Maintenance and Support | Easy to maintain, with good support and spare parts. |

| Cost | Balances price with features and reliability. |

| Supplier Reputation | Trusted supplier with strong service and quality. |

| Safety Features | Protects workers and meets safety rules. |

| Training and Installation | Offers help with setup and training for your team. |

You need trained workers to use these machines. Training teaches people to use the machine safely. It also shows how to keep it working well. Some training is online. Some is hands-on. Some workers get help from mentors. Training helps your team find problems early. They can fix things fast.

Maintenance keeps your machine in good shape. If you check your machine often, it works better. You will have fewer problems. Well-kept machines make better cups. You get fewer bad cups. You also save money by avoiding big repairs. Your work stays on schedule.

Online training for sheet extrusion

Hands-on practice and testing

Mentoring for practical skills

Regular checks and servicing

Preventive maintenance for longer machine life

Adding new machines to your line can be hard. You must make sure the new machine fits with your old setup. Everything needs to work together. Sometimes you need to change things for new materials. You may want more ways to make different cups.

The cup thermoforming machine faces many challenges. These include material limits, higher energy costs, and the need for more flexible production. To be efficient and eco-friendly, you must solve these problems.

Customization lets you get more from your machine. You can set the temperature, pressure, and cycle times. This helps you work better and waste less. Custom settings let you make special cup designs. You can meet new market needs. Flexible machines help you work faster and support the environment.

You can make better cups by using smart machine designs. The table below shows what helps most:

| Design Feature | Description |

|---|---|

| Heating Temperature | Careful heating keeps cups strong and the same. |

| Mold Design | Good molds make cups with smooth sides and easy to take out. |

| Pressure Level | The right pressure makes cups with the right thickness. |

| Material Properties | Using good material gives you better cups. |

| Cooling Rate | Fast cooling stops problems and keeps cups looking good. |

Hengfeng’s thermoforming machines use new technology and work well. To get better cups, you should:

Use smart automation to control your machines.

Do regular checks and fix your machines often.

You can make up to 120 cups every minute. This speed helps you finish big orders quickly. The machine works faster than many other machines in the market.

You can use PP, PS, PET, and PLA. These materials work well for making strong, safe cups. You can also choose eco-friendly options for your business.

The tilting action spreads the plastic evenly. You get cups with the same thickness and fewer weak spots. This means your cups look better and last longer.

Yes! The quick-change mold system lets you switch designs in 15 to 20 minutes. You can meet new market needs without long delays.

Hengfeng gives you training, setup help, and fast service. You get answers to your questions and help with repairs. This support keeps your machine running well.