Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

You can see how a pulp thermoforming machine is changing packaging. This technology uses recycled paper to make containers. These containers break down very fast. Molded pulp has a much lower carbon footprint than plastics. It biodegrades in less than 90 days. Many companies now use pulp molding. International orders are growing quickly. By picking this option, you help cut waste. You also help protect the environment.

Pulp thermoforming machines use recycled paper to make green packaging. This packaging breaks down fast and helps cut down on waste.

These machines make production faster and more efficient. Companies can fill orders quicker and spend less money than with old methods.

Using pulp packaging can save a lot of money. Molded fiber pulp costs much less than plastic packaging.

Pulp packaging can be made in many ways to fit different needs. This helps brands look unique and meet what customers want. It also makes products more attractive.

Pulp thermoforming machines help the planet by using less plastic. They also lower carbon footprints and support green goals.

Pulp thermoforming machines turn recycled paper into packaging. The process starts with old paper, cardboard, or plant fibers. These materials get mixed with water to make pulp. The pulp goes into molds. Heat and pressure shape the pulp into strong items. The shaped items get dried to take out water. Workers or machines cut the edges to make them neat. Some products get coatings or polish to look better and work well. Each item gets checked to make sure it is safe. Finished products are packed for shipping.

Tip: Using recycled paper and plant fibers helps lower waste and is good for the planet.

Here is a table that lists the main steps:

| Step | Description |

|---|---|

| Raw Material Preparation | Pulp is made from recycled paper and plant fibers. |

| Molding | Pulp is shaped with heat and pressure in molds. |

| Drying | Molded items are dried to remove water. |

| Edge Trimming | Edges are cut for a neat finish. |

| Surface Treatment | Coatings or polish are added for better looks and use. |

| Quality Control | Items are checked for safety and quality. |

| Packaging | Finished items are packed for shipping. |

| Export and Distribution | Products are sent to different places. |

There are different ways to make paper pulp packaging. Dry pressing shapes, dries, and trims in separate steps. Wet pressing does these steps together for smooth items. Semi-dry pressing gives medium detail. Direct pressing skips drying to save energy.

Thermoforming machines can make many kinds of paper pulp packaging. These machines help make packaging that is good for the earth. The packaging can be recycled, composted, or thrown away after use. You can make trays, plates, and packaging that protects things.

Eco-friendly packaging

Recyclable packaging

Compostable packaging

Disposable packaging

Trays and other items

Many industries use paper pulp packaging, such as:

Packaging

Plant growing

Online shopping

Factories

Building

Paper pulp packaging is used in many ways. Here are some examples:

| Application Type | Description |

|---|---|

| Inner Industrial Package | Used for electrical equipment |

| Electric Tools | Holds tools like drills and saws |

| Car Parts | Packs parts for cars |

| Lamp & Lanterns | Protects lighting products |

| Shoe Tree | Shapes and supports shoes |

| Compressor of Air-condition | Packs HVAC parts |

| Electronic Products | Protects electronics |

| Instrument | Packs different instruments |

| Communication Apparatus | Packs devices for communication |

Paper pulp packaging gives many choices for different needs. Using recycled paper and plant fibers helps nature. It also helps companies that want to be green.

Image Source: pexels

Pulp thermoforming machines help you work faster. You can plan your work better with these machines. They let you pick preset patterns for molding. This makes your job easier and more steady. It helps you fill orders quickly and spend less money. Older ways of packaging cost more and take longer.

Here is a table that shows how these machines help:

| Evidence Description | Impact on Production Efficiency |

|---|---|

| Optimization model integrates molding pattern selection with production scheduling | Improves operational efficiency |

| Using preset settings for molding patterns enhances production planning | Yields lower costs and improved demand fulfillment over traditional methods |

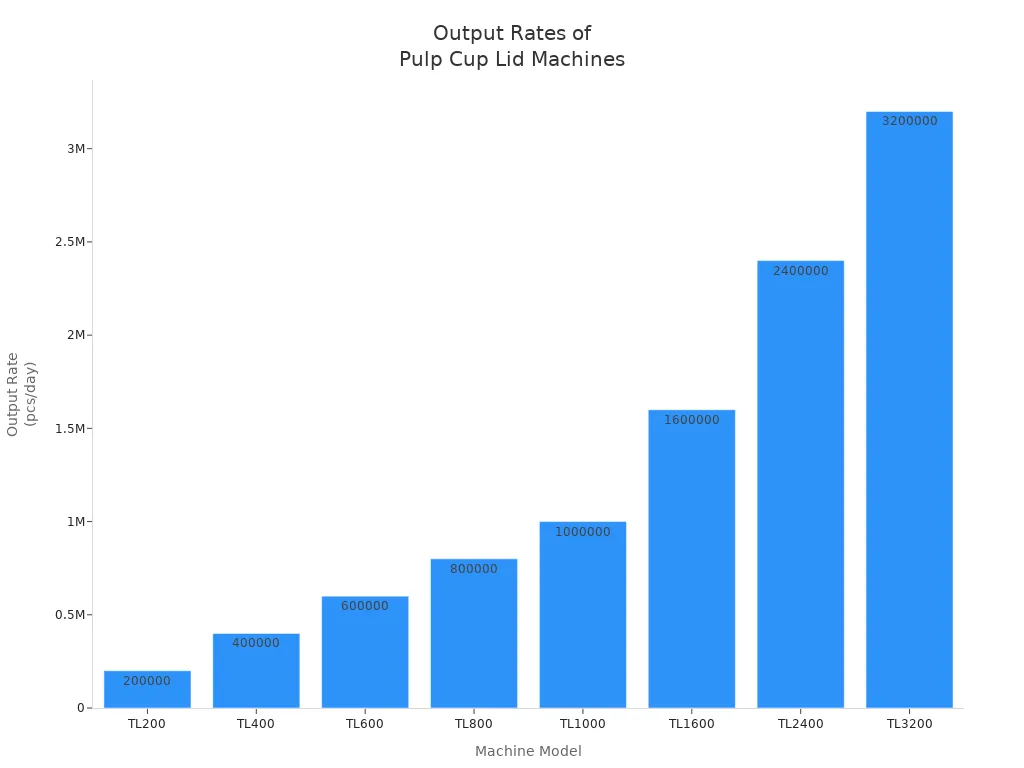

These machines can make thousands of items every day. For example, a pulp molding cup lid line can make up to 3,200,000 pieces daily. This speed helps you finish big orders on time.

| Machine Type | Daily Output (kgs) | Output Rate (pcs/day) |

|---|---|---|

| Regular Speed Pulp Molding Machine | 620~670 (Oil Heating) | N/A |

| 737~811 (Electric Heating) | N/A | |

| Pulp Molding Cup Lid Production Line | N/A | 200000 (TL200) |

| N/A | 400000 (TL400) | |

| N/A | 600000 (TL600) | |

| N/A | 800000 (TL800) | |

| N/A | 1000000 (TL1000) | |

| N/A | 1600000 (TL1600) | |

| N/A | 2400000 (TL2400) | |

| N/A | 3200000 (TL3200) |

Note: One small company used a desktop thermoforming machine. They finished jobs 30% faster. They also wasted 25% less material. Some new companies made money in their first year because these machines are flexible and cheap.

You save money when you use pulp thermoforming machines. These machines use recycled stuff, which costs less than plastic. Molded fiber pulp packaging costs 50to50to150 per ton. Plastic packaging costs 800to800to1200 per ton. This big price gap helps you spend less and earn more.

| Machine Type | Cost Range |

|---|---|

| Thermoforming System | 120,000−120,000−1.2 million |

| Plastic Packaging (per ton) | 800−800−1200 |

| Molded Fiber Pulp (per ton) | 50−50−150 |

Molded fiber pulp packaging is cheaper, costing 50to50to150 per ton.

Plastic packaging costs much more, from 800to800to1200 per ton.

You get good value for your money. Many companies work faster and waste less. For example, one small company made things 30% quicker and used 25% less material. Some new businesses made profits in their first year because these machines are low-cost and flexible.

You can make special packaging with pulp thermoforming machines. These machines let you change shapes, sizes, and looks. You can design packaging that fits your products well. Your packaging can look different from others. This helps your brand stand out and meet customer needs.

Thermoforming is easy to adjust. You can make packaging for different industries. This means your products work better and look nicer. You can also try new styles for holidays or special editions without spending too much.

Here is a table that shows how design choices help your brand:

| Customization Option | Benefit for Branding |

|---|---|

| Complex Geometries | Enables intricate shapes and detailed textures, enhancing product uniqueness. |

| Customizable Finishes | Offers a variety of surface finishes and colors, improving visual appeal. |

| Efficient Sizing for Product Fit | Tailors packaging to product dimensions, enhancing protection and reducing waste. |

| Flexibility for Seasonal Editions | Allows experimentation with new styles for limited editions without high costs. |

Thermoforming lets brands make special packaging.

Custom finishes make your brand look different.

Exact sizing keeps products safe and cuts down on waste.

You help the earth when you pick pulp packaging. Pulp molding machines are better for nature than plastic packaging. They use recycled materials and make things that break down fast. You support green choices and help cut down waste in packaging.

Tip: If you switch to pulp thermoforming machines, you work faster, spend less, and get cool design options. You also help the planet by choosing sustainable packaging.

Image Source: pexels

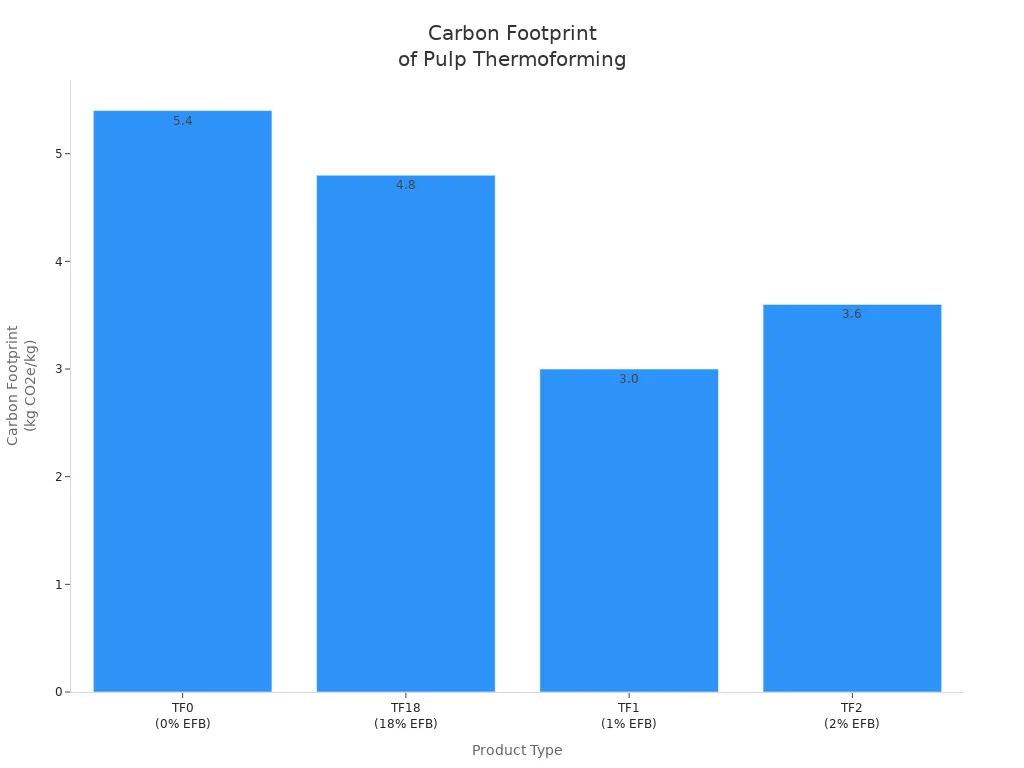

When you pick pulp thermoforming machines, you help the earth. These machines use less energy and water than making plastic. This means fewer greenhouse gases go into the air. Molded pulp packaging can lower emissions by up to 80% compared to plastic. You also use less electricity and natural gas, so there is less pollution.

Here is a table that shows how pulp products compare to plastic trays:

| Product Type | Carbon Footprint (kg CO2e/kg) | Reduction Compared to PP (%) |

|---|---|---|

| TF0 (0% EFB) | 5.4 | 6% |

| TF18 (18% EFB) | 4.8 | 21% |

| TF1 (1% EFB) | 3.0 | N/A |

| TF2 (2% EFB) | 3.6 | N/A |

Adding more natural fibers makes the carbon footprint smaller. Using 18% EFB fibers cuts emissions by 17%. Trays with EFB fibers have a lower carbon footprint than polypropylene trays.

Pulp molding puts out 92% less CO₂ than regular plastics. Choosing paper pulp packaging helps the planet more than petroleum-based options.

Using recycled paper and natural fibers is good for the environment. Pulp thermoforming machines turn waste paper and farm leftovers into new packaging. Molded pulp can be recycled many times, so you help keep materials in use. This process means we need fewer new resources.

Pulp thermoforming machines make packaging that is eco-friendly and useful.

Molded pulp packaging breaks down and does not release toxins.

Molded pulp can be recycled again and again, which cuts down on waste.

Pulp molded packaging uses 40–50% less energy and water than plastic packaging.

You help turn farm waste into useful pulp. This keeps waste out of landfills and gives old materials new life.

Switching to paper pulp packaging helps cut down on waste. Thermoforming machines use recycled materials, so fewer new resources are needed. Molded pulp replaces single-use plastics, keeping more plastic out of nature.

Thermoformed molded pulp breaks down, can be composted, and recycled.

You keep products safe while helping the earth.

Dry Molded Fiber technology lets you swap single-use plastics for pulp packaging.

Fast production of molded pulp makes it easier to stop using plastic.

Here is a table that shows how molded pulp helps cut plastic use:

| Evidence Description | Impact on Plastic Use |

|---|---|

| Molded pulp is an environmentally friendly alternative to plastic food packaging. | Can replace or reduce plastic use in packaging. |

| Molded pulp decomposes quickly in the natural environment after disposal. | Supports sustainability goals by minimizing plastic waste. |

| Dry Molded Fiber technology enables companies to replace single-use plastics. | Directly contributes to reducing plastic packaging. |

| The technology allows for high-speed production of molded pulp products. | Facilitates the transition from plastic to sustainable packaging solutions. |

Every time you choose pulp packaging, you help the environment. You support green choices and lower packaging waste.

Tip: Picking paper pulp packaging makes a big difference. You lower your carbon footprint, use recycled paper, and help keep plastic out of nature.

Many new business chances are coming with pulp thermoforming machines. The world market for these machines may reach over $4.6 billion by 2035. Molded pulp packaging machines could be twice as popular by 2033. This is because more industries want packaging that is better for the earth.

The sustainable packaging market will grow from [52.4billionin2024](https://www.towardspackaging.com/insights/thermoform−packaging−market−size)to52.4billionin2024](https://www.towardspackaging.com/insights/thermoform−packaging−market−size)to93 billion by 2034.

The U.S. market for sustainable packaging could reach $600 billion as people pick eco-friendly products.

80% of shoppers say they will pay extra for packaging that helps the planet.

You can sell to new markets like foodservice, electronics, and online shopping. In 2024, foodservice packaging output went up by 18%. Many new machines now work with biodegradable coatings. Hybrid systems help you make products 25% faster and change tools 30% quicker.

| Evidence | Description |

|---|---|

| Demand Growth | Foodservice pulp packaging output rose by 18% in 2024. |

| Machine Orders | 60% of new machines support biodegradable resin coatings. |

| Hybrid Systems | Pilot lines saw 25% faster development and 30% less tool changeover time. |

You need to keep up with what buyers and rules want. People want packaging that does not hurt the earth. Many look for compostable materials and special designs. Companies use machines to lower costs and make more items.

| Consumer Trend | Impact on Molded Pulp Packaging |

|---|---|

| Shift towards sustainability | More demand for eco-friendly materials |

| Innovative packaging solutions | Growth in food, beverage, electronics, and e-commerce |

| Compostable materials | More use of sugarcane pulp and new coatings |

| Automation in production | Lower costs and better efficiency |

| Customization | Personalized packaging for brands and online sellers |

You also have to follow strict rules about the environment. The European Union does not allow some single-use plastics. Many countries now make companies use biodegradable materials. These rules make the packaging industry buy more pulp thermoforming machines and use green solutions.

Tougher rules around the world help cut plastic waste.

Many places ban plastics that do not break down.

Companies must use eco-friendly packaging to keep selling products.

You get help from new technology in pulp thermoforming machines. New machines work faster and better. Automated controls and servo motors save energy and make things run smoother. Machines now use plant fibers like bagasse and wheat straw.

| Feature | Description |

|---|---|

| Eco-friendly Packaging | Uses renewable plant fibers for biodegradable products |

| Advanced Automation | PLC control makes operation easier and more efficient |

| Energy Efficiency | Servo motors cut energy use |

| High Production Capacity | Machines produce up to 800 kg daily |

Research and new ideas are changing paper pulp packaging. Dry-molding methods make production quicker. Better coatings keep out gas and liquids. You can now make packaging that looks and works like plastic but is better for the earth.

New technology helps make products from renewable materials. These changes help you reach green goals and make products better.

You will see more growth and new things in packaging as technology and what people want keeps changing.

You can see how pulp thermoforming machines make packaging better. Companies like GreenPack Solutions and EcoGoods Manufacturing save money and waste. They also sell more products.

| Case Study | Company Name | Impact Description | Benefits Achieved |

|---|---|---|---|

| Case Study 1 | GreenPack Solutions | Switched from plastic to biodegradable packaging. | Cut production costs by 30% |

| Case Study 2 | EcoGoods Manufacturing | Improved their products with pulp thermoforming machines. | Lowered material waste by 40% |

Experts think more people will want sustainable packaging soon. There are some problems you might face. You need a lot of money to start. It can be hard to find enough raw materials. Other green technologies also compete with pulp thermoforming.

You need a big investment at first.

Sometimes, it is hard to get raw materials.

Other green options are also popular.

You can team up with research groups and try new machines. This can help your business grow. Picking pulp thermoforming helps the earth and gets you ready for the future.

Paper pulp packaging keeps products safe. It is made from recycled paper and plant fibers. This packaging breaks down fast. It helps cut down on waste.

Thermoforming machines help lower pollution. They use less energy and water than making plastic. These machines also keep plastic out of landfills.

You can recycle molded pulp packaging. Many recycling centers take it. Recycling keeps materials in use. It helps make the planet cleaner.

You can make trays, plates, cup lids, and packaging that protects things. Many industries use these for food, electronics, and shipping.

Paper pulp packaging is safe for food. It meets safety rules. It does not let out harmful chemicals. Many restaurants and stores use it for takeout.