Views: 0 Author: Site Editor Publish Time: 2025-09-08 Origin: Site

Chinese plastic thermoforming machines follow world rules for quality and new ideas. The market is growing fast. The Chinese industry thinks it will grow 3.8% each year from 2024 to 2035. This is a bit more than the world’s average of 2.8%. New ideas help make machines work better and faster. Makers work on packaging that is good for the planet. Buyers pick thermoforming machines that are steady and work well for packaging.

Chinese plastic thermoforming machines follow global quality rules. This makes them safe and reliable for buyers.

Automation helps these machines work faster. Factories can make more products with less energy. There are fewer mistakes too.

More people want eco-friendly packaging now. So, makers build machines that use recycled and biodegradable materials.

Regular checks and certifications like ISO9001 help people trust Chinese manufacturers. Global buyers feel more confident.

Companies can customize machines for their own needs. This gives them more choices in how they make things.

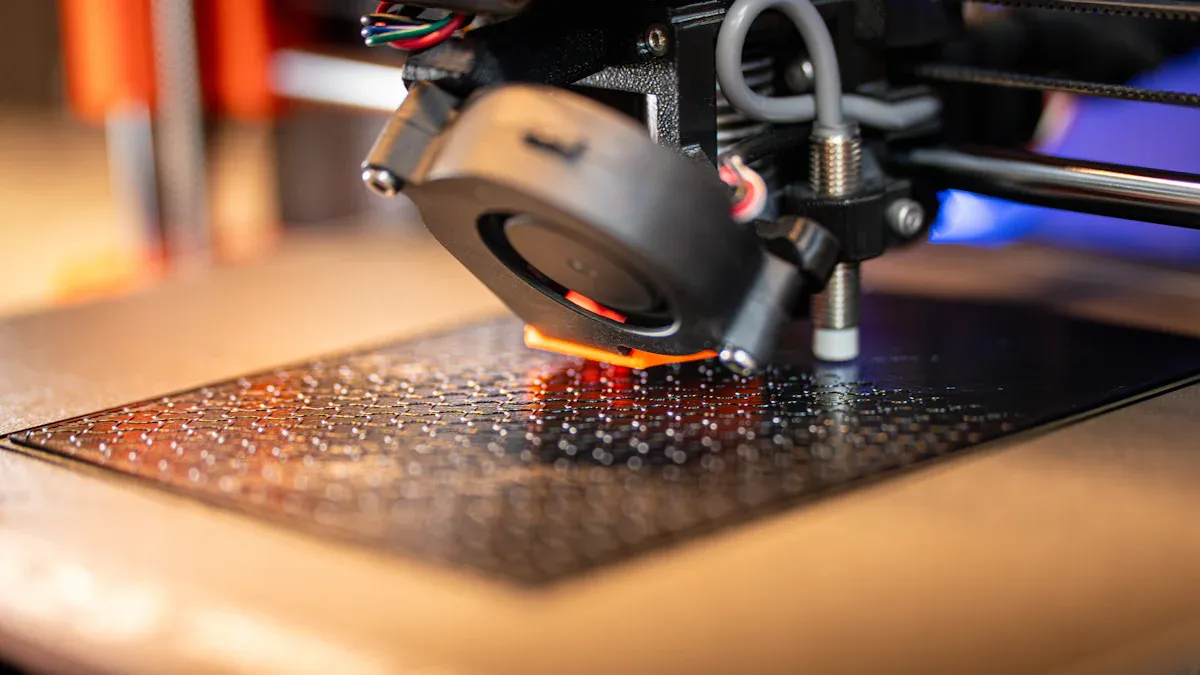

Image Source: unsplash

Chinese plastic thermoforming machines must follow strict world rules. Many companies try to get certifications to show they care about quality. The most popular certification is ISO9001. This means a company uses a good system to manage quality. Litai Machinery Co., Ltd. has more than 20 years of experience. They use ISO9001 to help make their machines. Companies with these certifications show buyers they can match top brands.

Note: Certifications like ISO9001 help buyers feel sure about the safety and reliability of high-quality vacuum forming machinery.

Chinese makers use many steps to check machine quality. They look at how machines are made and the final product. Litai Machinery and other companies use strong quality checks. These checks help find problems early and fix them before shipping. High-quality vacuum forming machinery must pass lots of tests before leaving the factory.

Sometimes, common problems happen in thermoforming equipment. Chinese makers fix these problems with clear steps. The table below lists some usual problems and how companies solve them:

| Common Issue | Description | Troubleshooting Solution |

|---|---|---|

| Heating Inconsistencies | Uneven heating can cause bad forming and poor products. | Check heating parts for damage, clean or change broken parts, and make sure everything lines up right. |

| Mold Defects | Cracks or bad alignment can hurt product strength. | Look at molds for damage, fix or change them, and keep them clean to stop dirt from building up. |

| Vacuum System Failures | Problems can cause incomplete forming or air bubbles. | Check for leaks, change old parts, and do regular maintenance. |

| Material Feed Issues | Bad feeding can make products not line up right. | Check feed parts for jams, change feeding speed, and teach workers how to handle things right. |

| Cooling Problems | Not enough cooling can make products bend or change shape. | Check cooling systems, clean channels, and set cooling times to match what is needed. |

Workers learn to find these problems fast. They also do regular checks and maintenance to keep high-quality vacuum forming machinery working well. This focus on quality helps Chinese plastic thermoforming machines build a good name around the world.

More people want thermoform packaging machines now. Many businesses need better ways to pack things. The food and drink industry needs safe packaging. These companies want machines that make strong packages. Healthcare and pharmaceutical companies also need these machines. They must follow strict rules for packaging. These rules help keep products safe.

People worry about the environment. This changes what buyers want. Makers now create packaging that is better for the planet. The plastics processing machinery market is moving toward green choices. Buyers want machines that help the earth. The global vacuum forming machine market grows because of this. People want machines that use less plastic and waste.

The need for thermoform packaging machines is getting bigger. This is because people and companies care more about the planet. They also want better packaging for their products.

China is a top maker of vacuum forming machines. The country makes 140K units, which is about 72% of Asia’s total. By 2035, China may make 97K units each year. The yearly growth rate is 3.8%. This is higher than the world average. China’s role in the market is getting bigger.

Chinese companies sell machines to many countries. More people in other countries want these machines. Buyers in Europe, North America, and Southeast Asia pick Chinese machines. They like them because they work well and cost less. The market keeps growing as more businesses use new packaging machines.

China sells many machines and meets rising demand. This shows China is a leader in the global vacuum forming machine market.

Image Source: unsplash

Chinese plastic thermoforming machines have changed a lot lately. Makers now use more automation to make things better. Many factories use platforms that run by themselves. These platforms use smart robots and data to help. They can control production with little help from people.

Modern thermoformers have smart temperature systems. These systems watch and change heat all the time. They keep the heat steady, only changing by about 1°C. This helps make better products with fewer mistakes. Fast molding drive technology is also important. It makes the molding process over 20% quicker. This lets factories make more items in less time.

Factories now use technology that saves energy and helps the earth. These systems save energy while making products. They use about 15% less power. This is good for the planet and saves money.

Platforms with robots and data help run production.

Smart temperature systems keep heat steady for good products.

Fast molding drive technology makes production quicker.

Energy-saving systems use less power and help the earth.

More people want automatic roll-fed thermoformers. Companies need fast and cheap ways to pack things. These machines turn plastic rolls into many kinds of packages. They help food, drink, and medicine companies work faster. Automation helps factories make more and better products. This makes Chinese brands stronger around the world.

Servo motor technology gives very good control. This helps make better products and less waste. It also helps save energy and supports green ideas. Chinese makers use new technology to lead the market.

Automation in thermoformers makes them flexible, cuts mistakes, and boosts how well they work. Companies that use these systems often become top sellers.

Efficiency is very important for new ideas in thermoforming. In the last five years, Chinese makers have made big improvements. They work on saving energy and using resources better. New thermoformers use up to 15% less energy than old ones. Factories found that making air and heating use the most energy. By fixing these, they save even more power.

| Improvement Type | Description |

|---|---|

| Energy Efficiency | New machines use up to 15% less energy than old ones. |

| Energy Consumption Focus | Making air and heating use the most energy. |

| Optimization Potential | These areas can save a lot of energy during thermoforming. |

New ideas in vacuum thermoforming help control heat better. Thermoformers now heat plastic sheets more evenly. This stops wasting energy and keeps plastic from bending. Automation also helps set up machines faster and needs less work from people. These changes make production faster and products better.

New technology lets factories change what they make quickly. They can switch between products with little waiting. This helps companies give customers what they want. The market likes companies that use new and energy-saving technology. Good performance and efficiency make Chinese thermoformers stand out.

Companies that work on efficiency and new ideas get a strong place in the world market. Their thermoformers work well and cost less for buyers.

Plastic vacuum forming machines use new technology to shape plastic sheets. These machines can make many different products. Chinese plastic thermoforming machines now have more automation. Automation helps save money and makes things faster. Machines can load and unload materials on their own. They also control vacuum and pressure very well.

Some new trends in plastic vacuum forming machines are:

| Trend | Description |

|---|---|

| Increased Automation | Machines do jobs like loading and controlling pressure by themselves. |

| Improved Materials | New plastics are lighter, stronger, and bend more easily. |

| 3D Printing Integration | 3D printing lets factories make hard shapes without costly molds. |

| Increased use of Thermoforming | Thermoforming works with vacuum forming for better results. |

| Improved Software and Technology | Software helps control and watch machines, making work faster and easier. |

| Increased use of Sustainable Materials | Machines use more recycled and earth-friendly plastics. |

| Multi-Layer Materials | These materials make products stronger and better with heat. |

| In-Mold Decorating (IMD) | IMD puts designs on products during forming, so they look nice and last longer. |

Plastic vacuum forming machines now use smarter software. Workers can see what is happening right away. This helps them fix problems fast. Machines also use less energy, which saves money and helps the planet. Many factories use multi-layer materials to make strong products. In-mold decorating makes packaging and goods look better.

Plastic vacuum forming machines help many industries. They let companies make things quickly and for less money. The main uses are:

Car parts like covers and inside trim

Signs and display cases for stores

Custom parts for small jobs

Testing new product ideas

Cosplay and costume pieces that are hard

These machines work for big or small jobs. Companies use them to try new ideas before making lots of products. Plastic vacuum forming machines also let factories change what they make easily. This helps many kinds of businesses.

Note: Plastic vacuum forming machines are very important today. Their new technology and many uses help lots of industries.

Thermoform packaging machines are important in many industries. Companies pick these machines because they work fast and save time. They also help keep products safe from harm. The food industry uses them to pack snacks, dairy, and meals. Medical companies use them for pills and medical tools. These machines help keep things clean and safe.

Makers of home goods use these machines for their products. Car companies use them to make car parts that are light and strong. Many businesses like these machines because they have many good points:

They make packaging last a long time.

They keep products safe from dirt and damage.

They can pack many shapes and sizes.

They save money for big and small jobs.

They let companies make special packages.

They help make products quickly and easily.

Thermoform packaging machines help companies follow safety rules. They also let companies change products fast. This makes them a smart pick for many kinds of work.

Note: Thermoform packaging machines help both big factories and small shops. They give safe and flexible ways to pack products.

Makers build thermoform packaging machines for each industry’s needs. These machines can make many shapes and sizes. Companies can change the look of their packaging fast.

The table below shows how top makers help with custom needs:

| Manufacturer | Customization Capabilities | Industry Focus |

|---|---|---|

| Qualipak Machines | Special packaging and quick help for customers | Food, personal care, chemicals, drinks |

| Smart Pack Machine | Custom designs and special parts for each job | Food, medicine, electronics |

Plastic thermoforming equipment lets companies ask for special features. They can get packaging that fits their products. New machines use smart controls to make changes easy. This helps companies sell new products faster.

Thermoform packaging machines help companies look different from others. They can make packaging that matches their brand and keeps products safe. Chinese plastic thermoforming machines are known for being good and flexible.

Big manufacturers in China are important in the world market. They are known for making good, new, and reliable machines. Many buyers want to buy from brands they trust. The table below shows some of the best companies:

| Manufacturer Name |

|---|

| Zhongnuo Equipment |

| Guangzhou Kinte |

| Anhui Kingpower |

| Anhui Sunmine |

| Qingdao Ouxin |

These top companies in China use advanced technology. They always work to make their machines better. Each company spends money on research to improve. They also try hard to meet world rules and help their customers.

Chinese manufacturers have helped the plastic thermoforming industry grow. They make machines that are fast and save energy. Their machines are easy for workers to use. Many companies use automation and smart controls. This helps factories work faster and make fewer mistakes. Some companies make special machines for food, medicine, or electronics.

Top Chinese companies sell their machines to many countries. They help other businesses pack products better. They also give good help and training after selling the machines. This makes it easier for buyers to use the machines well and safely.

Manufacturers keep working to make their machines better and cheaper. They add new things like energy-saving parts and lines that can change fast. These changes help them stay ahead of others. Because of this, Chinese companies are now leaders in the world market for plastic thermoforming.

Note: Chinese manufacturers care about quality and new ideas. Their machines help many businesses grow and keep up with new needs.

Chinese plastic thermoforming machines help the market care for the environment. Makers now try to use less waste and make things greener. They use recyclable materials like PET and PLA. These materials help cut down on waste. They also make the process better for the earth. Some factories say they waste 30% less material than before.

Makers build machines that use biodegradable and recycled plastics. This helps the market move toward greener ways. Companies must follow tougher rules about waste and pollution. They use new systems to recycle scraps and keep things clean.

Circular economy steps help companies save resources. They also help them meet world rules for caring for the environment.

Energy efficiency is important for new plastic thermoforming machines. Chinese makers use technology that needs less energy. These machines help lower pollution and reach green goals. Many factories use motors and smart controls that save power.

The table below lists main green actions:

| Initiative Type | Description |

|---|---|

| Biodegradable Materials Processing | Machines can use biodegradable materials. |

| Recycled Plastics Processing | Machines work with recycled plastics. |

| Energy-Efficient Technologies | New tech helps use less energy. |

| Environmental Compliance | Companies follow stricter green rules. |

Makers meet new rules for energy and pollution. They follow government laws and handle waste better. These actions help the market grow and make buyers trust them.

Tougher rules for energy use

Laws about pollution

Better waste handling

Chinese plastic thermoforming machines now lead in green ideas. Companies answer the world’s call for eco-friendly choices. They set new standards for caring for the earth.

Many buyers from other countries think Chinese plastic thermoforming machines are good and reliable. Makers like Ruian Bocheng Machinery Co., Ltd. work hard to help customers and keep machines running well. Their strong focus on quality helps buyers trust them. Companies want machines that can pack many things and change with the market. When makers listen to what buyers say and make their machines better, buyers feel sure about what they buy.

Chinese makers have some problems in the world market. These problems are:

New equipment and technology cost a lot at first.

There are tough rules about energy and pollution that change often.

Makers must work hard to fix these problems. They buy better systems and teach workers new rules. This helps keep machines safe and ready to sell to other countries.

Chinese makers have many chances to grow in new places. Some big changes help this growth:

Fast building and city growth in Asia-Pacific means more packaging is needed.

Online shopping is growing, so more things need strong packaging for shipping.

More companies want packaging that is good for the earth, so makers use recycled and biodegradable materials.

Automation and digital tools help factories work faster and save money, so smart machines are easier to offer.

These changes help makers build better machines and find more buyers. As more people need packaging, Chinese plastic thermoforming machines can help businesses keep up and follow world trends.

Chinese plastic thermoforming machines are now known for being very good and new. Many companies try to use less energy and more recycled materials in packaging. Some new things are happening:

New ways to mold and green materials help make packaging better for the earth.

The market is growing quickly in Asia-Pacific because more companies want light and green packaging.

Machines keep getting better with more automation and work faster, so buyers like them.

Chinese makers will probably be leaders as people want better packaging. Buyers should notice both the good points and how this industry keeps getting better.

Most Chinese machines have ISO9001 certification. This means the company uses a good quality system. Some machines also meet CE or UL safety rules. Buyers can ask to see these certificates before buying.

Manufacturers give training, spare parts, and technical help. Many companies have online help and fast support teams. Good service after buying helps keep machines working well.

Yes, many Chinese machines use motors that save energy. They also have smart controls to lower power use. These features help factories spend less money and meet green goals.

Buyers can ask for special features, sizes, or functions. Manufacturers work with customers to design machines for their products. Custom machines help companies be different in the market.

Industries like food, healthcare, cars, and electronics use these machines. They help make packaging, trays, car parts, and more. Many businesses pick them for speed, flexibility, and saving money.