Views: 0 Author: Site Editor Publish Time: 2025-09-08 Origin: Site

Automation is making plastic thermoforming different. You can make things faster now. The products look better and cost less to make.

Smart temperature control keeps the heat even. This helps make products the same every time.

Fast molding can make things 20% quicker.

New robots and vision systems find problems fast. They help you waste less material. Many companies use automation because there are not enough workers. They also want to work faster. Think about how these changes in thermoforming can help your business do more.

Automation makes plastic thermoforming faster. Companies can make products 20% quicker and work more efficiently.

Smart technology, such as sensors and AI, helps make better products. It finds problems early, cuts down on waste, and keeps things the same each time.

Automation helps companies spend less on workers and materials. This saves a lot of money over time.

Robots and advanced control systems help make production smoother. They make it easier to fill big orders and keep quality high.

Spending money on automation pays off fast. Many companies see good results in 12 to 36 months.

Automation helps you work faster in plastic thermoforming. Machines can make more products in less time. MedPlast Solutions used robots to move parts. This made loading and unloading twice as fast. The company finished cycles 20% quicker and made better products.

Here is a table that shows some main ways automation helps:

| Efficiency Gain | Description |

|---|---|

| Heightened Efficiency | Automation makes production cycles shorter, so you make more products faster. |

| Improved Product Quality | Automation lowers mistakes from people, so products look the same and meet rules. |

| Cost Efficiency | You save money over time by needing fewer workers, making less waste, and using less energy. |

| Waste Reduction | Machines use materials better, so you waste less and spend less on supplies. |

Fast thermoforming machines work quickly and make fewer errors. You get more products and use your machines better. Automation keeps things steady, so you can trust your results every time.

Automation helps you check product quality in new ways. Sensors and smart cameras look at each product as it comes out. This lets you find problems early and keep products looking the same.

Automation with AI and machine learning can help make manufacturing more steady. It does this by watching machines, fixing problems before they happen, and changing controls when needed.

Machines do the same steps every time, so you get fewer mistakes and less waste. One company used a PLC system to control heating, forming, and cooling. This made scrap rates drop by 15% and parts more consistent.

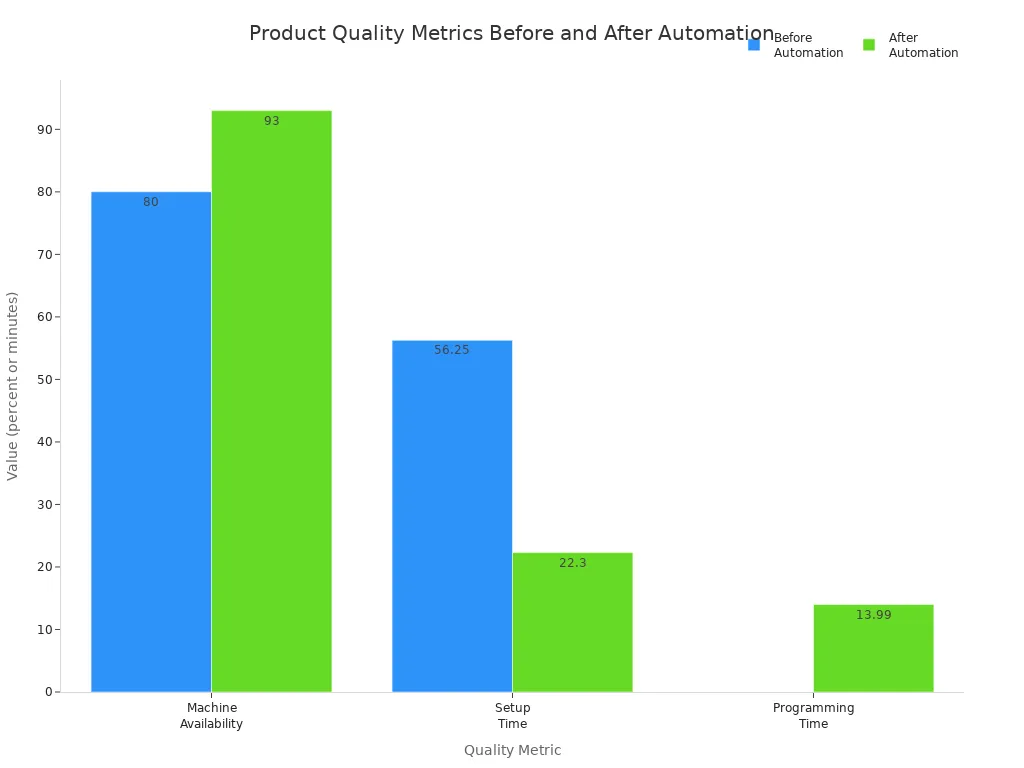

The chart below shows how automation made things better:

You can see machines were used more, setup took less time, and programming was faster. These changes show automation helps keep production smooth.

Automation helps you save money in plastic thermoforming. Machines need fewer workers, so you pay less for labor. They use materials smarter, so you waste less and save money.

Tooling costs are lower: Thermoforming tooling costs much less than injection molding tooling.

Less material waste: Smart machines use materials well, so you save a lot.

Energy efficiency: New machines use less energy, so your bills go down.

Robots and automatic checks mean you need fewer workers.

Fully automatic machines can do many jobs at once, making your line work better.

Automation in plastic thermoforming helps you save money, make better products, and work faster. You can meet higher standards and keep up with demand while spending less.

Factories have fewer workers now. Many companies cannot find enough people for plastic thermoforming jobs. This problem makes you use automation more. Machines help keep things running when you cannot hire more staff. You can make more products without needing extra workers.

Here is a table that shows how automation helps with labor shortages:

| Benefit | Description |

|---|---|

| Increased Scalability | You can grow your production and meet bigger orders. |

| Less Labor Needed | Machines do the hard work, so you need fewer people. |

Manufacturers want to use their workers better. Automation helps you get more done and not rely on hiring new people.

You must make products faster than before. More people want fully automatic thermoforming machines for quick production. Food, beverage, medicine, and consumer goods companies all need speed.

Automation helps you keep up with lots of orders.

Machines work faster than people and match fast equipment.

You also want cleaner and safer work. Automation helps you meet hygiene rules, which matter more since the pandemic. You can finish orders on time and keep customers happy.

You want every product to be high quality. Automation gives you better control in thermoforming. Real-time monitoring and data tools help you find problems early. You can fix things before they become big issues.

Advanced sensors and control systems help you control the process well. You get the same quality every time and have less downtime.

Automation helps you work better and trust your products. You know your machines will give you good results each time.

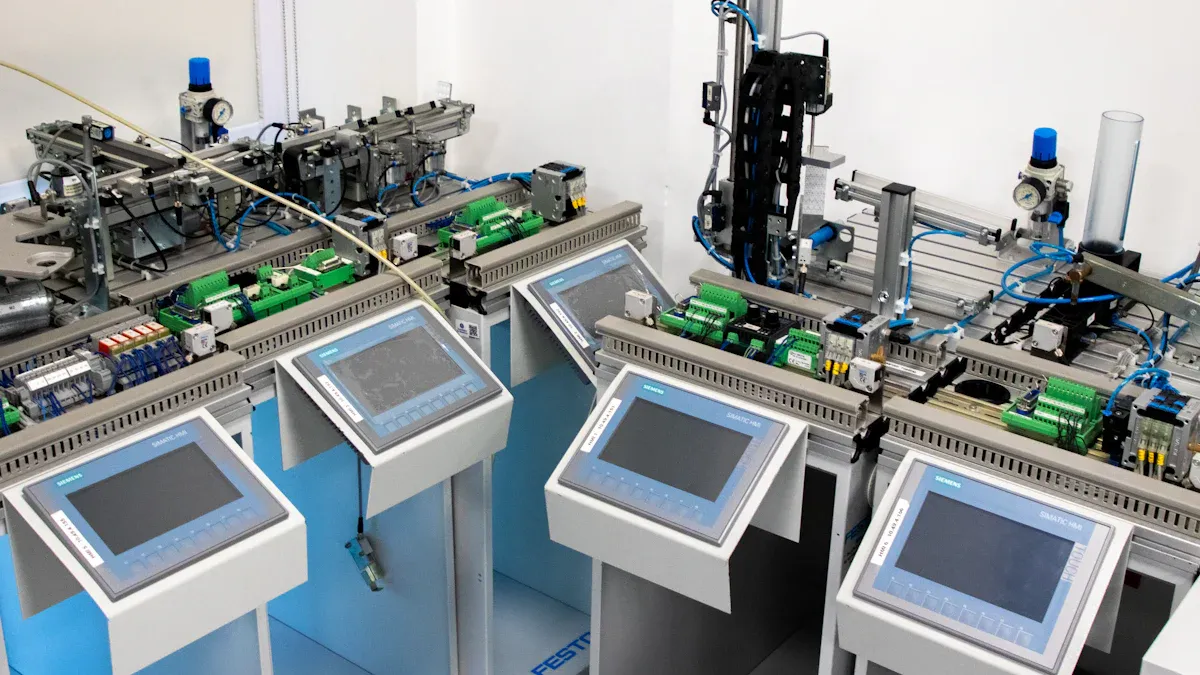

Image Source: pexels

Robots and cobots are used more each year in plastic thermoforming. These machines help with tough jobs or jobs that take a long time. Robots can load and unload parts, trim edges, and polish surfaces. Robots work fast and never get tired, so you make more products.

The UR10e cobot trims plastic parts at Kal Plastics. It makes trimming quicker and more exact.

The Grit cobot from Kane Robotics sands, grinds, deburrs, and polishes. You can use it for many hard jobs in thermoforming.

Cobots help with sanding and polishing. These steps are needed to make smooth products.

“No matter how long you have been a thermoformer, a cobot is a great choice. You may not be able to buy a new CNC, but you can get a cobot.” — Dan Sproles, consultant for KAL Plastics

Small companies can use cobots too. Cobots cost less than big machines and help you keep up with orders. Robots also help make every product look the same.

Advanced control systems help you get the best results from your thermoforming machine. These systems use sensors, motors, drives, PLCs, and HMIs to watch and control each step. You can change things right away to keep everything steady.

Here is a table that shows how advanced control systems help:

| Evidence Description | Contribution to Process Optimization |

|---|---|

| Advanced process control systems monitor many things at once | Lets you change settings quickly to keep production running well |

| Temperature sensors give feedback for heating in certain zones | Helps control heating better and makes products higher quality |

| Pressure and vacuum monitoring systems keep forming conditions steady | Makes sure molds are even, so you work faster and better |

You use these systems to control temperature, pressure, and vacuum. This helps you make products that meet high standards. Fast thermoforming machines use these controls to keep up with quick lines. You get less waste and better products every time.

AI and smart monitoring change how you run plastic thermoforming machines. You can watch your machines as they work and find problems before they stop production. New sensors and AI help you plan repairs and avoid delays.

AI lets you change forming settings by itself. Machine learning helps you get good results every time. You use less material and keep things running smoothly. Smart monitoring connects your machines to experts, so you get help fast.

AI and robotics together make thermoforming better. They help with loading, unloading, and checking quality. You make more products and move toward smart factories. Using these tools helps you stay ahead in the industry.

Blow and vacuum forming shape plastic into many products. You heat a plastic sheet first. Air or suction forms it over a mold. Automation helps control each step. Machines move sheets and heat them evenly. They use the right pressure every time. This gives you the same shape each time. Your products are more reliable. Machines work faster than people. You save time with automation. The process stays steady, even with many parts made in one day.

Thermoforming is flexible and saves money. You heat a plastic sheet and shape it with a mold. Many industries use this method, like packaging and technology. Modern machines use automation to handle materials. They trim parts while production keeps going. Robotic arms move sheets quickly and safely. In-line trimming cuts parts to size without stopping. These new machines help you work faster. You make high-quality products quickly. Automation gives you more control and better results.

It helps you work faster.

Product quality stays the same every time.

Automated packaging is used for food trays and medical kits. Automation brings many benefits to packaging in plastic thermoforming. Machines form, cut, and stack products in one system. This makes work easier and faster. Fewer workers are needed because machines run many lines. You get better quality, which is important for medical packaging.

| Advantage | Description |

|---|---|

| Improved Product Quality | Automation makes products more consistent and high quality, which is important for medical packaging. |

| Increased Production Quantity | Automated systems work all the time, so you make more products. |

| Reduced Labor Intensity | Fewer people are needed since machines handle many lines, helping with worker shortages. |

| Streamlined Tooling Processes | Automation lowers mistakes when changing tools and moving heavy materials. |

| Intuitive Human-Machine Interfaces | Modern HMIs are easy to use, so training is faster and work is easier. |

| Integration of Functions | Automation combines forming, cutting, and stacking, so you work better. |

| Scalability and Throughput | Automated systems can grow to meet demand without needing more workers. |

Tip: Automated packaging helps you meet demand and keep quality high.

Image Source: unsplash

Plastic thermoforming machines are changing a lot now. New automation solutions help you work faster and make fewer mistakes. Advanced robotics can make your production quicker and more exact. This matters a lot for medical and automotive industries. Every part needs to be perfect in those fields.

Here are some ways automation helps your thermoforming process:

Robotics move materials fast and keep workers safe.

BMG’s systems let you change tools quickly and use robot simulation to plan.

Easy-to-use technology makes stacking, racking, and packing simpler and better.

You can count on these machines for hard jobs. They keep your line running and help you reach high standards. Automation means you do less manual work and spend more time making good products.

Modern control and monitoring systems give you more control over machines. You can watch each step and fix problems right away. These systems help you keep temperature and pressure steady. This way, you get the same results every time.

Here is a table that shows how these features help you:

| Feature | Benefit |

|---|---|

| Real-time data monitoring | You fix problems fast and make fewer bad parts. |

| Remote access | You control machines from anywhere and respond quickly. |

| Data analytics and storage | You learn from trends and plan repairs before issues happen. |

| Safety systems | Alarms warn you about danger and keep your team safe. |

| Customization options | You set machines for your needs and work more efficiently. |

| IoT integration | You watch all machines together and use less energy. |

These tools help you make your plastic thermoforming process better. You save energy, keep workers safe, and make sure every product is up to your standards.

When you add automation, your team must learn new things. Some workers might feel worried about using new machines. You can help by giving them training and support. This makes everyone feel sure and ready to use advanced technology. Some jobs will change. People may move from hands-on work to watching and controlling machines. This change can make your team better and more skilled.

Tip: Tell your team to ask questions and share ideas in training. This helps build trust and lets everyone get used to changes faster.

All parts of your thermoforming process need to work together. Sometimes, it is hard to connect new automation with old machines. You can use tools like ProfiNet and EtherCAT to help machines talk to each other. These tools work with many types of equipment.

SAY Plastics made their process better by using real-time data from ERP systems. Teams could watch job status, check inventory, and get alerts for problems. The table below shows how each step fits together:

| Step in Process | Description |

|---|---|

| Roll Changing | Setting up materials for forming |

| Infeed/Outfeed | Moving materials into and out of machines |

| Heating Elements | Getting materials ready for forming |

| Process Control | Making sure everything works right |

| Mechanical Pressing | Shaping the heated material |

| Vacuum Control | Forming the material into molds |

| Trimming | Taking off extra material |

| Cutting | Making the final product shape |

| Inspection | Checking the finished product |

When you connect all these steps, your line works better and you find problems early.

Starting automation can cost a lot at first. The price depends on the system, how hard your process is, and how many machines you need. Some companies get their money back in 7 to 18 months, especially with custom, high-performance systems. AI-powered automation can give you a 15-30% return in the first year. Most businesses see good results in 12 to 36 months. Simple projects pay off fast, but bigger ones take longer.

You should check your budget and goals before you spend money. Think about how quickly you want results and how much you can spend. Planning carefully helps you get the most from your automation in thermoforming.

AI and smart controls will be used more soon. These systems help machines work faster and better. AI-powered vision systems look at every product as it comes out. They find problems right away and help keep quality high. You can choose your own rules for good products. The system learns from each check and gets smarter over time. Here are some ways AI helps:

AI-powered vision systems check products by themselves.

The system finds problems during making and tells you fast.

You can pick your own rules for good or bad products.

Machine learning gets better at finding problems each time.

You do not need to check by hand as much, so work goes smoother.

Smart controls link with your whole thermoforming line. You get updates right away and can look at old problems quickly. This makes your work more steady.

There will be more focus on sustainability in plastic thermoforming. Automation helps you use less energy and make less waste. Many companies use recycled or biodegradable plastics now. New machine designs help you use materials in smarter ways. Here are some trends to watch:

Machines use less energy, so you save money.

More recycled and biodegradable plastics are being used.

New designs help you waste less and use materials better.

These changes help you follow new rules and show customers you care about the earth.

The industry will grow as more companies want better packaging and faster work. Experts think the automatic plastic thermoforming machine market will grow 5-7% each year for five years. There will be more need for eco-friendly packaging and less waste. Food, healthcare, and consumer goods companies will help this growth. Smart factories will change thermoforming in the future. You will use IoT and AI to watch machines live and fix problems before they stop work. Smart technology helps you use resources better and save energy.

You should expect faster work, better products, and greener choices as technology gets better.

You can see that automation is making plastic thermoforming better. Recent examples show big improvements in how things are made:

| Benefit | Description |

|---|---|

| Increased Throughput | Automated systems run all the time, so you make more products. |

| Consistency | Automation helps every product look the same and be high quality. |

| Labor Savings | You need fewer workers, so you spend less money and make fewer mistakes. |

Make sure your machines and workers are ready for these new changes. Keep learning from top companies and try out new digital tools.

The industry is always changing with new technology.

Companies like Ray Products follow new trends.

Industry 4.0 and digital tools help you do your job better.

Thermoforming will keep getting better as technology improves.

Automation means using machines and smart tools to help with thermoforming. These machines help you make things faster and better. Robots, sensors, and computers do some jobs for you. This means you do not have to work as hard.

You pay less for workers and materials. Machines use less energy and make less waste. You can make more products in a shorter time. This helps you spend less and earn more money.

Yes, small companies can use simple robots or control tools. Cobots are good for small businesses. You do not need a lot of money to start. Many small companies grow after using automation.

You should learn how to use the control screens and programs. Training helps you know how sensors and robots work. You do not need to be a pro. Most machines have easy screens to use.

Automation makes your workplace safer for everyone. Machines do the heavy and risky jobs. You can watch the process and check quality. Safety systems warn you about problems before accidents happen.