Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

Cup Thermoforming Machines help companies make cups from plastic sheets fast. These machines use automation to make more cups and save money on workers. Workers can do special jobs while machines do the same tasks again and again. Many companies pick these machines because they help make more products and stay ahead of others. The world market may reach $4.0 billion by 2025, with a 7.5% growth rate.

| Year | Market Size (USD Billion) | Growth Rate (%) |

|---|---|---|

| 2025 | 4.0 | 7.5 |

Hengfeng is a top company with smart solutions that save energy and help the environment.

Cup Thermoforming Machines make cups automatically. This helps make more cups faster. It also lowers the need for workers and saves money.

Hengfeng's machines can make up to 55,000 cups each hour. Manual methods only make about 8,000 cups per hour. This helps businesses fill big orders easily.

These machines can use many kinds of plastics. They can also use biodegradable plastics. This helps companies be more eco-friendly.

Taking care of the machines helps them last longer. With good care, they can work for over 20 years. This keeps them working well for a long time.

Hengfeng gives good help after you buy the machine. They teach workers how to use the machines. They also give spare parts quickly. This helps companies keep their machines working well.

Image Source: pexels

Cup Thermoforming Machines change plastic sheets into cups using several steps. Each step helps make sure the cups are strong and look nice. First, the process starts with extrusion. In this step, plastic pellets melt and turn into flat sheets. Next, the sheets go to the thermoforming stage. Here, machines heat the sheets and shape them into cups with vacuum or pressure. After that, the cups cool down fast. This helps them keep their shape and stay strong. Then comes curling. The top edge of each cup rolls out to make a smooth rim. This makes the cup easier to use and more comfortable. The last step is quality testing. Workers or machines check the cups for size, strength, and how they look.

| Step | Description | Contribution to Quality |

|---|---|---|

| Extrusion | Raw plastic pellets melt and form into continuous sheets. | Ensures consistent thickness for the intended cup type. |

| Thermoforming | Heated sheets shape into cups using vacuum or pressure forming. | Allows for efficient production and detailed designs. |

| Cooling | Cups cool quickly to maintain shape and strength. | Prevents warping and preserves details during setting. |

| Curling | The cup's top edge rolls outward for a smooth rim. | Enhances comfort, strength, and lid fit. |

| Quality Testing | Cups are checked for dimensions, strength, and appearance. | Ensures only high-quality cups meet standards. |

Hengfeng's Multistation Thermoforming Machine and Tilting Cup Making Machines do these steps automatically. These machines use servo motors and special controls to keep each step exact. The Multistation model can switch molds fast and uses both air pressure and vacuum to form cups. The Tilting Cup Making Machines use a cam-driven system. This makes them fast and strong. Both models help companies make more cups quickly and with fewer mistakes.

Hengfeng's machines can make 250% more cups and cut cycle time by 40% compared to regular machines. They also work with many plastics, even biodegradable ones. These features make Hengfeng's Cup Thermoforming Machines a good choice for making lots of cups.

Manufacturers use different plastics to make cups with Cup Thermoforming Machines. Each plastic has good and bad points. Polyethylene is light and cheap. It works for many things but cannot handle high heat. Polypropylene bends easily and is simple to use. It is not as stiff as some plastics but is common for food packaging.

| Material | Advantages | Disadvantages |

|---|---|---|

| Polyethylene | Lightweight, cost-effective | Limited temperature resistance |

| Polypropylene | Good flexibility, easy to process | Can be less rigid than other options |

Hengfeng's machines can use many materials, like PP, PS, PET, and PLA. This helps companies meet different needs and follow new trends.

Cup Thermoforming Machines have many important parts. Each part helps the machine work well and make good cups.

| Component | Role in Machine Performance |

|---|---|

| Heating Element | Melts thermoplastic material to shape it effectively. |

| Forming Station | Shapes the material into the desired cup form. |

| Cutting Mechanism | Ensures precise cutting of the formed cups for quality output. |

The heating system melts the plastic sheets. It uses heating elements and controls to keep the heat steady.

The forming station shapes the cups. It uses molds and vacuum or pressure to make the right shape.

The cutting mechanism trims the cups. It makes sure each cup has smooth edges and the right size.

The cooling system helps the cups set fast. It keeps the cups strong and stops them from warping.

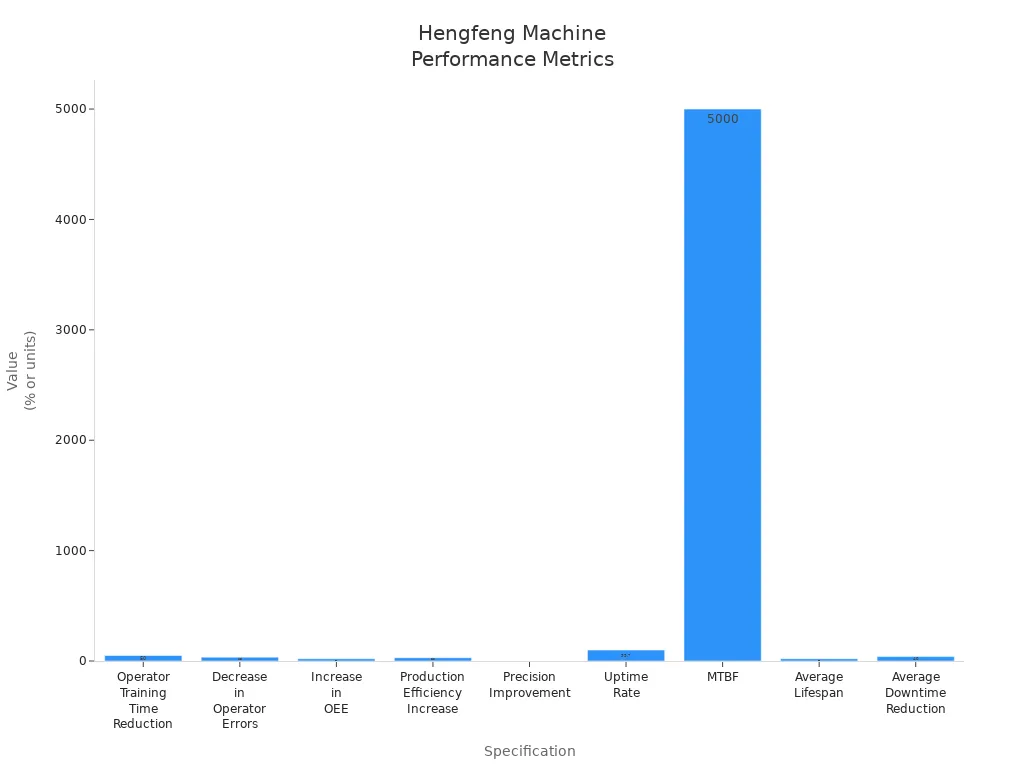

Hengfeng's Multistation Thermoforming Machine and Tilting Cup Making Machines use advanced parts. These machines cut training time for workers by half and lower mistakes by 35%. They make cups with precision up to 0.05mm and keep running 99.7% of the time. The machines last over 20 years and can run for 5,000 hours before needing repairs. These features help companies make great cups with less downtime.

Cup Thermoforming Machines from Hengfeng use smart design and new technology. They help companies make more cups, save energy, and keep quality high.

Cup Thermoforming Machines help companies make cups fast. New machines work much quicker than old ones. Automatic machines can make up to 55,000 cups in one hour. Manual machines only make about 8,000 cups in that time. This big difference helps businesses meet more orders and grow faster.

| Method | Production Speed (cups/hour) |

|---|---|

| Automatic Thermoforming | 55,000 |

| Manual Machines | 8,000 |

Hengfeng's machines use servo motors and smart controls. These features keep things running smoothly and lower mistakes. The Tilting Cup Making Machines can make up to 120 cups each minute. This speed helps companies fill big orders and stay ahead.

Cup Thermoforming Machines help companies save money in many ways. They use less energy and need fewer workers. Hengfeng's Tilting Cup Making Machines cut labor costs by 60%. The machines also use less power, saving up to 30% compared to older models.

| Key Advantages | Description |

|---|---|

| High Speed | Very fast cycle times are great for making lots of cups. |

| Low Tooling Costs | Molds are simple and made from aluminum, so they cost less than injection molds. |

Tip: Making cups in bigger batches helps companies use materials better and lowers the cost for each cup.

Regular care and good setup also save energy. Companies can plan batches, train workers, and use energy monitors. These steps lower energy costs, help the environment, and support growth.

Cup Thermoforming Machines make cups that look good and are always the same. Hengfeng's machines use smart technology to keep every cup the same size and shape. The servo drive system and temperature controls help keep quality high in every batch. Multi-cavity molds let companies make more cups at once.

| Feature | Benefit |

|---|---|

| Advanced thermoforming tech | Makes cup production more exact |

| Servo drive systems | Helps make cups quickly |

| Intelligent temperature control | Keeps quality the same in every batch |

| Multi-cavity mold configurations | Lets companies make more cups and change easily |

Hengfeng's Tilting Cup Making Machines have ISO 9001 certification. This means they follow strict quality rules. The machines lower defects to less than 0.1%. Companies can trust that every cup will look good and work well.

Cup Thermoforming Machines can make many kinds of cups. They work with different shapes, sizes, and materials. Hengfeng's machines switch molds quickly, so companies can change cup designs fast. The machines work with plastics like PP, PS, PET, and PLA. This helps companies keep up with new trends and customer needs.

"The Fully Automatic Plastic Cup Thermoforming Machine can use many types of plastic, each with special features, so it can make high-quality, valuable plastic cups."

| Cup Shape | Description |

|---|---|

| Round Cups | Made with standard thermoforming. |

| Square Cups | Good for special designs and stacking. |

| Conical Cups | Used for special looks and uses. |

Companies can make cups for drinks, food, and special needs. Fast mold changes and flexible settings help them adjust production easily. This versatility helps businesses grow and serve more customers.

Image Source: unsplash

Cup Thermoforming Machines are important in food and drinks. Big brands like Starbucks and McDonald's use these machines. They make cups for drinks and food fast. The machines help companies make many cups that look the same. They work for disposable cups, ice-cream containers, and sour milk packs. The machines also let companies make special packages for different needs.

| Application Type | Description |

|---|---|

| Plastic Drinking Cups | A huge market for thermoforming machine products. |

| Disposable Plastic Cups | Used for cold drinks, sour milk, ice-cream, and fast food. |

| Customizable Packaging Solutions | Strong containers, trays, and cups for green packaging needs. |

Stores and brands want cups with cool designs or logos. Cup Thermoforming Machines help companies make custom cups for their brand. These machines give lots of choices for design and finishing. Companies can pick shapes, colors, and sizes they like. They can add extra steps to make the cups better.

| Customization Option | Description |

|---|---|

| Design | Special designs for branding and store needs. |

| Post-production machining | Extra steps to make the final cup nicer. |

| Finishing | Different ways to make cups look and work better. |

| Tooling manufacture | Custom tools for new cup shapes and sizes. |

| Assembly | On-site help for full packaging solutions. |

| Thermoformed packaging | Special packaging that is light but strong. |

Machines make cups that look the same every time.

New trim press technology helps work faster.

Solutions can fit different company goals.

Thermoforming makes packaging light and strong. These cups look good in stores and stay safe when shipped.

Many companies want cups that help the planet. Cup Thermoforming Machines can use bio-based materials like corn starch and PLA. These make cups that break down over time. The machines use heat, vacuum forming, and cooling to make cups strong and light. These cups are biodegradable and help cut down on trash.

| Feature | Description |

|---|---|

| Raw Materials | Uses bio-based stuff like corn starch and PLA for green tableware. |

| Environmental Focus | Made to protect nature and work well. |

| Production Process | Uses heat, vacuum forming, and cooling for strong, light, and green cups. |

| Applications | Good for food packaging, catering, and industry. |

Machines help companies make eco-friendly packages.

Smart technology makes sure green cups are high quality.

Companies can sell products that help the earth.

Manual models need people to control each step by hand. Workers put in plastic sheets and set the heat. They also shape the cups themselves. These machines are good for making a few cups at a time. They do not cost much and fit in small spaces. People can learn to use them fast. But these machines make fewer cups. The cups can look different from each other.

Semi-automatic machines mix hand work with some machine help. Workers put in the plastic and take out the cups. The machine heats and shapes the cups by itself. These machines are good for small businesses that want to work faster. Each machine still needs one worker. They make more cups than manual models. But how fast they work depends on the worker.

Fully automatic machines do almost everything on their own. They load, heat, shape, cut, and stack cups without stopping. One worker can watch many machines at once. These machines are best for big factories that need lots of cups. They cost more and need more room. The cups all look the same and the machines can run all day and night.

Note: Fully automatic machines help companies use fewer workers and keep cup quality high.

| Comparison Aspect | Manual Thermoforming Machine | Semi-Automatic Thermoforming Machine | Fully Automatic Thermoforming Machine |

|---|---|---|---|

| Automation Level | None | Medium | Very High |

| Production Efficiency | Very Low | Lower | Very High |

| Labor Requirement | Higher | Higher | Very Low |

| Initial Investment | Lower | Higher | Substantially Higher |

| Product Consistency | Variable | Variable | Exceptionally High and Stable |

| Flexibility | Very High | Very High | Lower |

| Floor Space | Smaller | Smaller | Larger |

| Skill Requirement | Lower | Lower | Higher |

Hengfeng makes special machines that are better than many others. The Multistation Thermoforming Machine uses servo motors. This helps it move exactly and change molds quickly. It can use many kinds of plastic, even ones that are good for the earth. The Tilting Cup Making Machines use a cam system. This makes them fast and strong. Both machines are easy to use and built very well. Hengfeng’s machines help save energy and keep making cups without stopping.

| Feature | Hengfeng Multistation | Other Machines |

|---|---|---|

| Intuitive Operational Design | Yes | Sometimes |

| Cutting-edge Innovation | Yes | Varies |

| Tailor-made Solution Proficiency | Yes | Limited |

| Premium Engineering Craftsmanship | Yes | Varies |

| Eco-friendly Power Optimization | Yes | Rare |

Cup Thermoforming Machines from Hengfeng give companies machines that work well, make cups fast, and use less energy.

Production volume is important when picking a machine. If a company makes only a few cups, it can use manual or semi-automatic machines. Medium businesses often pick automatic machines. Big factories need fast, fully automatic machines to meet demand. The table below shows which machine fits each size of production.

| Production Scale | Machine Type |

|---|---|

| Small-scale production | Manual or semi-automatic machines |

| Medium-sized production | Automatic thermoforming machines |

| Large-scale production | High-speed, fully automatic machines |

Big companies need machines that make lots of cups quickly. Fast machines with high automation are best for making many cups.

Material compatibility is important when choosing a machine. Some machines work with many plastics. Others only work with a few types. Hengfeng’s Cup Thermoforming Machines can use PET, PP, PS, and biodegradable plastics. This lets companies make cups for different uses and follow new trends.

| Plastic Type | Compatibility with Machines |

|---|---|

| PET | Yes |

| PP | Yes |

| PS | Yes |

| Biodegradable | Yes |

Companies should check what materials they need before buying a machine.

Budget matters when picking a machine. Manual and semi-automatic machines cost less. They are good for small workshops. Automatic thermoforming lines cost more. They help medium companies grow. Full turnkey systems cost the most. They fit big production needs. The table below shows the price for each type.

| Machine Type | Price Range | Suitable For |

|---|---|---|

| Manual/Semi-Automatic Machines | 15,000–15,000–40,000 | Small workshops or pilot production |

| Automatic Thermoforming Lines | 60,000–60,000–120,000 | Mid-sized packaging firms |

| Full Turnkey Systems | 130,000–130,000–200,000+ | Comprehensive production needs |

Tip: Companies should think about their budget and future growth. Energy efficiency is also important.

After-sales support helps companies keep machines working well. Hengfeng offers equipment customization, installation, repair, and training. These services help set up machines, fix problems, and teach workers. Good support means less downtime and better production.

| Service Type | Description |

|---|---|

| Equipment customization | Custom hot forming equipment for production needs. |

| Installation and debugging | Full setup and testing for efficient production. |

| Equipment repair and maintenance | Fast help for daily care and fixing problems. |

| Technical training and support | Training to help teams work better and faster. |

Picking the right Cup Thermoforming Machine depends on production needs, material compatibility, budget, and support. Energy efficiency and future growth also help companies stay ahead.

Taking care of cup thermoforming machines helps them work well. Doing daily, weekly, and yearly tasks stops problems and keeps cups looking good. The table below shows a simple plan for maintenance:

| Frequency | Maintenance Tasks | Description |

|---|---|---|

| Daily | Inspect Heating Elements | Check for damage or wear to avoid overheating. |

| Daily | Clean the Molds | Remove leftover plastic and debris for a smooth finish. |

| Daily | Check for Leaks | Look for leaks in the pressure system to keep efficiency. |

| Daily | Lubricate Moving Parts | Reduce friction and wear for longer machine life. |

| Daily | Document Daily Maintenance | Keep a log of all checks and tasks. |

| Weekly | Inspect Electrical Connections | Check for wear or corrosion to prevent failures. |

| Weekly | Clean the Cooling System | Flush out debris for proper cooling. |

| Weekly | Check the Pressure System | Inspect for leaks or wear to keep pressure steady. |

| Weekly | Review Safety Features | Test emergency stops and guards for safety. |

| Annual | Comprehensive Overhaul | Examine all parts and replace worn components. |

| Annual | Professional Inspection | Have a technician do a full check-up. |

Tip: Writing down maintenance helps find problems early and plan repairs before things get worse.

Operators sometimes have trouble with cup thermoforming machines. Fixing problems quickly keeps work going. The table below lists common problems and how to fix them:

| Operational Issue | Causes | Troubleshooting Steps |

|---|---|---|

| Inconsistent Heating | Faulty elements, wrong settings | Inspect and replace heating parts, check settings. |

| Material Feed Problems | Misaligned rollers, obstructions | Adjust rollers, clear feed path, replace rollers. |

| Malformed Products | Uneven material, wrong temp | Use even sheets, adjust mold temperature, check pressure. |

| Machine Downtime | Poor maintenance, failures | Follow routine care, inspect and replace parts. |

Note: Checking machines often and fixing problems fast helps stop long breaks and saves materials.

Good habits help machines last longer and work better. Operators should:

Check important parts often to find problems early.

Clean machines to stop wear and keep them working well.

Lubricate moving parts so they do not rub too much.

Watch how the system works for any changes.

Calibrate sensors and controls to keep things accurate.

Test safety features to keep workers safe.

Change old parts before they break.

Teaching operators and using good parts also helps machines last longer.

Hengfeng gives strong support to help customers keep machines working well. Their services include:

Training operators to use and care for machines.

Fast delivery of spare parts for quick repairs.

Technical help by phone or online to solve problems.

Ongoing help to keep machines reliable every year.

With Hengfeng’s support, companies can trust their cup thermoforming machines to work well and make good products.

Cup thermoforming machines help companies make cups faster. They also help make better cups and save money. These machines use automation and smart controls. This means every cup looks the same and there is less waste. Some machines save energy and can use biodegradable materials. This helps the environment. Hengfeng is a trusted company. They make advanced machines and give strong support.

Automation helps make good cups quickly.

Energy-saving designs help save money.

Machines can use green materials like PLA.

| Factor | Why It Matters |

|---|---|

| Material Compatibility | Fits what each company needs |

| Energy Efficiency | Saves money and helps nature |

| Support Services | Keeps machines working well |

Companies should think about what they need. They can ask Hengfeng for help and advice.

If you take good care of a cup thermoforming machine, it can work for more than 20 years. Cleaning, oiling, and changing old parts help it last longer.

Hengfeng machines use PP, PS, PET, and PLA. These plastics work for many cup styles, even ones that are good for the environment.

Operators need to check and clean machines every day. They should also look over machines each week and get a professional to check them once a year.

Yes. Hengfeng machines let you change molds quickly and pick special designs. Companies can make round, square, or conical cups for different uses.

Hengfeng gives training, sends spare parts fast, and offers technical help. Customers can get help by phone or online if they have problems.