Views: 0 Author: Site Editor Publish Time: 2026-01-09 Origin: Site

You find the blow-up ratio by dividing the bubble diameter by the die diameter. For example, if your bubble is 200 mm wide and the die is 100 mm, the blow-up ratio is 2. This number helps you control how thick and strong the film is. The table below shows how blow-up ratio, draw ratio, and final film thickness are connected in blown film extrusion.

| Parameter | Description |

|---|---|

| Blow-Up Ratio (BUR) | The ratio of the final tube radius to the initial tube outside radius just downstream of the die. |

| Draw Ratio (DR) | The ratio of the takeup speed to the die extrusion rate. |

| Final Film Thickness | Calculated using blow-up and draw ratios with the mass conservation equation. |

You can make your film better and more even by learning how to measure the bubble and figure out BUR. Hengfeng’s Sheet Extrusion Machine helps you control the bubble well for better results.

To find the blow-up ratio (BUR), divide the final bubble diameter by the die diameter. This helps you control how thick and strong the film is.

Pick a BUR that matches your material and what you want to make. A good ratio makes the film strong and even, with no problems.

Always measure the bubble at its widest part. Use the same units for both the bubble and the die. This makes your math correct.

Do not make mistakes like measuring the wrong way or using different units. These mistakes can make the film uneven.

Use Hengfeng’s Sheet Extrusion Machine to control BUR settings well. This helps you get the best film for many materials.

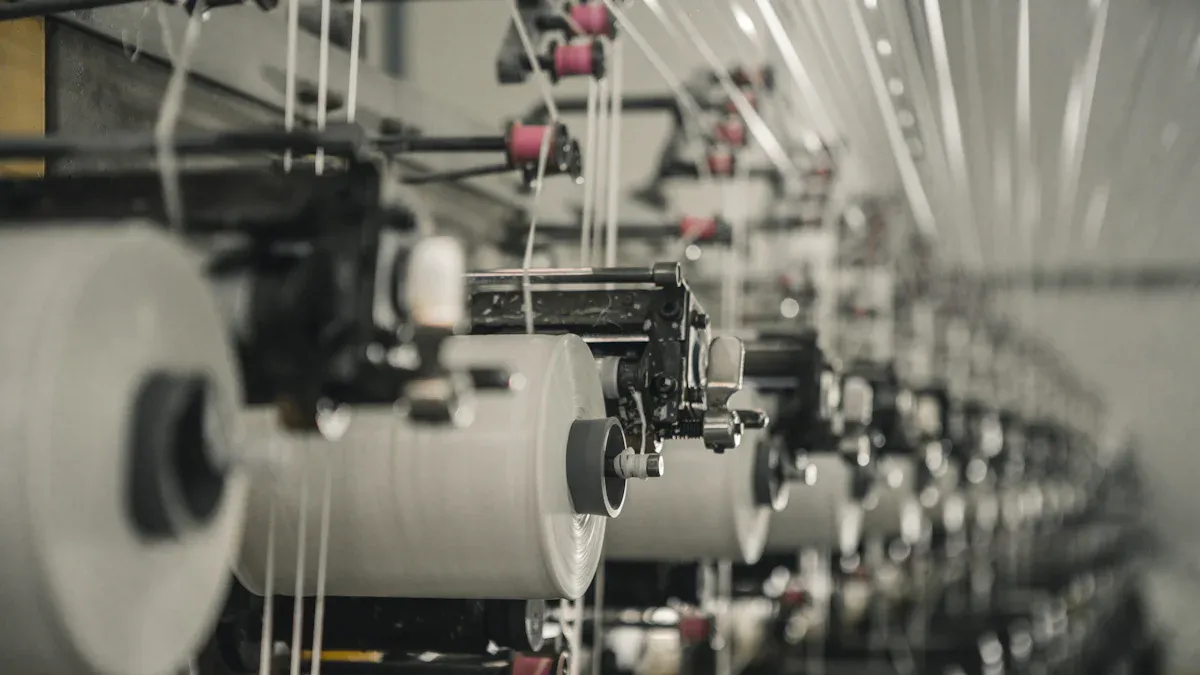

Image Source: unsplash

You can calculate the blow-up ratio using a simple formula. The blow-up ratio tells you how much the bubble expands compared to the die. This ratio helps you control the thickness and strength of the film during blown film extrusion.

Formula:

Blow-up Ratio (BUR) = Final Bubble Diameter / Die Diameter

You measure the final bubble diameter after the bubble has stabilized. You also need to know the die diameter, which is the size of the opening where the melted plastic comes out. Always use the same units for both measurements. If you measure the bubble in millimeters, measure the die in millimeters too. This keeps your calculation accurate.

The blow-up ratio affects the film’s properties. A low blow-up ratio can make the film split easily and cause uneven thickness. A very high blow-up ratio can make the bubble unstable and slow down production. You can see some common errors in the table below:

| BUR Range | Common Errors |

|---|---|

| Low BUR (Below 1.5:1) | - Splittiness: The film tears easily in vertical lines. |

| - Thickness Variation: Difficulty in even thickness distribution. | |

| Excessively High BUR (Above 4:1 or 5:1) | - Bubble Instability: Wobbly bubble leading to wrinkles. |

| - Lower Production Speed: Longer cooling time slows down production. | |

| - Port-Lines: Amplified die lines due to excessive stretching. |

You should aim for a blow-up ratio that matches your material and production needs. This helps you get a strong, even film.

Let’s walk through a sample calculation. You want to find the blow-up ratio for your film. First, measure the final bubble diameter. Suppose you get 200 mm. Next, measure the die diameter. Let’s say it is 100 mm.

Write down the formula:

BUR = Final Bubble Diameter / Die Diameter

Plug in your numbers:

BUR = 200 mm / 100 mm

Calculate the result:

BUR = 2

Your blow-up ratio is 2. This means the bubble is twice as wide as the die. You can use this number to adjust your machine settings. If you want a thinner film, you can increase the blow-up ratio. If you need a thicker film, you can lower the ratio.

Tip:

Always double-check your measurements. Use the same units for both the bubble and the die. This keeps your calculation correct and helps you avoid mistakes.

You can use this method every time you set up your blown film extrusion process. Accurate blow-up ratio calculation helps you make film that is strong, even, and meets your quality standards.

You use the blow-up ratio to compare the final bubble diameter to the die diameter in blown film extrusion. This simple number helps you control how much the bubble expands after leaving the die. When you set the right bur, you can make film that is strong, even, and clear.

The bur affects several important film properties:

The melt strength of the plastic decides how much you can stretch the bubble. If the melt strength is too low, the bubble can break, which changes the film thickness.

Strain hardening happens when you stretch the polymer. This process changes the film’s strength and uniformity.

The frost line, where the film cools and hardens, can move if the temperature is not even. This movement affects how uniform the film thickness is.

If you use the wrong bur, you may see problems like uneven film thickness, poor clarity, or weak spots. You want to avoid these issues to keep your film quality high.

| BUR Setting | Consequences |

|---|---|

| Low (Below 1.5:1) | Splittiness, Thickness Variation |

| High (Above 4:1) | Bubble Instability, Lower Production Speed |

When you work with Hengfeng’s Sheet Extrusion Machine, you can control the bur with precision. This control helps you produce film that meets your needs for thickness and strength. Hengfeng machines use advanced screw designs and temperature controls. These features help you keep the bubble stable and the film uniform.

You can adjust the blow-up ratio to match different materials, like PE or PP. Hengfeng’s machines let you change settings easily, so you get the best results for each type of film. If you want strong, clear, and even film, you need to pay attention to bur during production.

Tip: Always measure the final bubble diameter and die diameter carefully. Accurate measurements help you set the right blow-up ratio and avoid common problems.

Image Source: unsplash

To figure out bur, you must measure two things. First, measure the bubble diameter. Next, measure the die diameter. Use a caliper or ruler for both. Always check the bubble at its widest spot. This spot is usually right above the die. Be careful to get the numbers right. If you use millimeters for one, use it for both. This makes your bur calculation correct. It also helps you control how thick the film is.

Check the bubble at the widest spot above the die.

Use a caliper or ruler for both measurements.

Write down your numbers before you start.

You can make your bur calculation better by following some easy steps. Check your measurements often. Change your settings if you need to keep the film good. Try using a Blow Up Ratio Calculator for fast results. Test different bur settings to see what works best. Keep the temperature steady so the bubble grows evenly.

Tip: Get good data and look at your results often. Talk with your team about bur to share ideas and get better.

Watch and change bur as needed.

Use a calculator for exact numbers.

Keep the temperature steady.

Teach your team new ways to work.

You might have problems if you do not measure the bubble or die right. Things like temperature and humidity can change your bur. This can hurt your film. Do not use different units for your numbers. Do not forget to take care of your machine. Old parts can mess up your calculations. Always check your machine settings like temperature and pressure. This helps keep your bur steady.

| Mistake | How It Affects BUR and Film Quality |

|---|---|

| Measuring at the wrong point | Wrong bur, uneven film thickness |

| Using different units | Bad calculation, film is not even |

| Ignoring temperature changes | Bubble is not steady, film changes |

| Skipping machine maintenance | More mistakes, film is not as good |

Note: New sensor tools and in-line monitors help you watch bur all the time. These tools let you fix problems fast and keep your film good.

You need to choose the right bur for each material to get the best film quality. Different polymers work best with different bur settings. You can use the table below to find the recommended bur ranges for common materials. These values help you control the lay-flat width and make sure your film meets your needs.

| Polymer Type | Recommended BUR Range | Typical Lay-Flat Width Control |

|---|---|---|

| LDPE | 2.0 – 3.0 | Good for wide lay-flat width and flexible film |

| HDPE | 1.5 – 2.5 | Best for strong film and stable lay-flat width |

| PP | 1.6 – 2.5 | Useful for clear film and balanced lay-flat width |

| PA (Nylon) | 2.0 – 2.5 | Helps with tough film and consistent lay-flat width |

| EVA | 2.0 – 2.8 | Ideal for soft film and smooth lay-flat width |

You should always measure the lay-flat width after the bubble cools. This step helps you check if your bur setting matches your target film size.

When you adjust bur, you change how your film looks and performs. If you set bur too high, your film can become thin and weak. If you set bur too low, your film may turn stiff and lose strength in the transverse direction. You also affect the lay-flat width, which decides how wide your film will be after extrusion.

Tip: Use the right bur to balance film strength, clarity, and lay-flat width. Hengfeng’s Sheet Extrusion Machine lets you fine-tune these settings for each material.

Here is a table that shows how bur changes film properties:

| BUR Level | Effect on Mechanical Strength | Effect on Clarity | Effect on Barrier Performance |

|---|---|---|---|

| High | Poor mechanical strength, risk of tears | Variations in clarity | Barrier performance may drop |

| Low | Stiffer film, poor transverse strength | Clarity may improve | Barrier performance is adequate but not optimal |

You also need to watch thickness uniformity and surface quality. The table below explains how bur affects these aspects:

| Aspect | Effect of BUR |

|---|---|

| Thickness Uniformity | Wrong bur causes thin spots or thickness changes |

| Mechanical Properties | High bur lowers transverse strength, more tearing |

| Surface Quality | Low bur makes rough surface, high bur increases haze |

You can use Hengfeng’s advanced controls to set bur and lay-flat width for each run. This step helps you get film with the right thickness, strength, and clarity.

You now know how to calculate the blow-up ratio (BUR) in blown film extrusion. Measure the bubble and die diameters, then use the BUR formula. Accurate BUR helps you make strong, even film. Hengfeng’s Sheet Extrusion Machine gives you the control you need for top-quality results. Try these steps in your process. If you want expert help or advanced solutions, reach out to Hengfeng.

The blow-up ratio compares the bubble diameter to the die diameter. This number helps you control how thick and strong the film is when making it.

Measure the bubble where it is widest, just above the die. Use a ruler or caliper for this step. Always use the same units for both bubble and die sizes.

Changing the blow-up ratio changes the film’s thickness, strength, and how clear it looks. The right ratio helps you stop weak spots and uneven areas.

You can use many polymers like PE, PP, PET, and PLA. Hengfeng’s machine lets you change settings for each material to make the best film.

Do not measure at the wrong place or use different units. Always take care of your machine. These mistakes can make the film uneven and not as good.