Views: 0 Author: Site Editor Publish Time: 2025-09-05 Origin: Site

Industrial Thermoforming Machines heat and shape plastic sheets into exact shapes. They are important tools used in many factories around the world. These machines help industries that need fast and high-quality work. New technology like automation, robotics, and digital tools make these machines better. They now work faster and make better products. Companies use digital twins and AI to cut down on waste. These tools also help them work smarter. The global market is getting bigger:

| Year | Market Size (USD) |

|---|---|

| 2024 | 1,197.46 million |

| 2025 | 1,247.51 million |

Picking the right machine can help companies do their best work. It also helps them keep up with new technology and care for the environment.

Thermoforming machines heat plastic sheets. They shape them into many products. These machines are important in many industries. Some examples are automotive, medical, and packaging.

Picking the right thermoforming machine helps companies work faster. It also helps make better products. This helps companies stay ahead of others.

Automation and digital tools make thermoforming better. Machines can work faster and waste less material.

There are different thermoforming methods. Vacuum and pressure forming are two examples. Each method fits certain product needs. They help balance cost and detail.

Sustainability is very important now. Many companies use recycled materials. They also use machines that save energy. This helps lower harm to the environment.

Quality control technologies help check every part. Laser scanning and automated vision systems are examples. They make sure each part is made well.

Knowing market trends and new advancements is helpful. It lets companies change and grow in the industry.

Vendor support and customization are very important. They help companies get the best use from their thermoforming machines.

Image Source: unsplash

Thermoforming shapes plastic sheets into useful things. Factories use heat to make the plastic soft. Workers then put the soft plastic over a mold. The mold gives the plastic its new shape. This way, companies make food trays, car parts, and packaging. Industrial thermoforming machines are very important for this job. They help factories make lots of parts fast and with good quality. Many industries use these machines, like automotive, medical, and consumer goods.

Industrial thermoforming machines follow steps to shape plastic. First, the machine heats a plastic sheet until it bends easily. Next, the machine moves the sheet over a mold. The machine uses vacuum, pressure, or a plug to press the sheet into the mold. After shaping, the machine cools the plastic so it stays firm. At the end, the machine trims off extra plastic. This makes strong and exact parts.

Factories pick different machines for their needs. Some machines work best for simple shapes. Others can make more complex designs. The table below shows the main types of industrial thermoforming machines used in factories:

| Type of Machine | Description |

|---|---|

| Vacuum Forming Machine | Uses a vacuum to shape heated plastic sheets over molds. |

| Pressure Forming Machine | Combines vacuum and air pressure for complex shapes and details. |

| Twin-Sheet Forming Machine | Produces hollow products using two heated sheets formed simultaneously. |

| Plug-Assist Thermoforming Machine | Uses a plug to assist in shaping the plastic for intricate designs. |

| Rotary Thermoforming Machine | Designed for high-volume production with multiple rotating stations for efficiency. |

| Inline Thermoforming Machine | Features a linear configuration for sequential heating, forming, cooling, and trimming of sheets. |

Industrial thermoforming machines have many important parts. Each part helps the machine work well and make good products.

Heating Unit: This part heats the plastic sheet.

Forming Station: The machine shapes the plastic here.

Vacuum or Pressure System: These help press the plastic onto the mold.

Cooling System: This part cools the shaped plastic.

Trimming Station: The machine cuts off extra plastic.

Control Panel: Operators use this panel to control the machine.

Some machines, like rotary thermoforming machines, use many workstations to make more parts. Others, such as shuttle thermoforming machines, can make different sizes. Inline roll-fed machines use rolls of plastic to make things like food trays quickly.

Tip: Pick the right industrial thermoforming machine by looking at the product’s shape, size, and how fast you need to make it.

Vacuum forming is a common way to shape plastic. The machine heats a plastic sheet until it gets soft. Then, the machine uses a vacuum to pull the sheet over a mold. This shapes the plastic into what is needed. Many companies use vacuum forming for big and simple parts.

New ideas have made vacuum forming better and faster.

Automation now loads and unloads sheets, which saves time and money.

New plastics are stronger and can handle more heat, so parts are lighter and tougher.

3D printing helps make molds quickly, so companies can make special parts for less money.

Better software lets workers control the process more exactly, which makes things faster and better.

Many companies use recycled or biodegradable materials to help the environment.

Using layers and in-mold decorating gives parts more features and makes them look nicer.

Some machines, like the single-station vacuum former from Geiss AG, hold the sheet while shaping it. This helps each part come out the same every time. Halogen heating systems warm up the plastic faster, so more parts can be made quickly. Automated changeover systems let workers switch molds fast, which saves even more time.

Note: Vacuum forming is best for making lots of simple things, like trays, packaging, and panels.

Pressure forming is another way to shape plastic. It uses both a vacuum and high-pressure air to push the plastic over a mold. This makes parts with more detail and texture than vacuum forming. Pressure forming is good for things that need to look nice.

The table below shows how pressure forming and vacuum forming are different:

| Aspect | Pressure Forming | Vacuum Forming |

|---|---|---|

| Detail and Texture | Makes parts with lots of detail and texture | Makes parts with less detail |

| Production Speed | Slower because there are more steps | Faster, good for making many parts |

| Aesthetic Quality | Looks very nice, like injection molding | Not as nice looking |

Pressure forming is best for parts that need to be complex and detailed. It can make things with sharp edges and fine textures. But it takes longer than vacuum forming because there are more steps. Many companies use pressure forming for medical devices, control panels, and equipment covers.

Twin sheet forming is a special way to shape plastic. It uses two heated plastic sheets at the same time. The machine shapes both sheets over different molds and then joins them together. This makes hollow parts that are strong but not heavy.

The table below shows what is good and bad about twin sheet forming:

| Advantages | Limitations |

|---|---|

| Strong and lasts a long time | Can only make certain sizes |

| Uses light materials | Can only use some materials |

| Saves money | Tools cost a lot |

| Can make many shapes | Designs can be hard |

| Looks nice when finished | You can see where the sheets join |

| Can make big parts | Not many choices for surface finish |

Twin sheet forming is good for making things like pallets, tanks, and car panels. It makes parts that are strong and light. The process can make big parts and is flexible. But it costs more for tools and you can see where the sheets join. Companies need to think about these things before choosing this method.

Plug assist forming is a special way to shape plastic. A plug pushes the hot plastic sheet into the mold first. Then, vacuum or pressure shapes the plastic. The plug helps control how the plastic stretches. This makes the finished part have even thickness. Factories use plug assist forming for deep shapes and sharp details.

Many companies pick plug assist forming for making exact parts. Using a plug made from syntactic foam gives many good results. The foam plug helps the plastic spread out better. This means the part has better material all over. The plug lasts longer and needs less fixing. Factories save money because they do not change the plug often. Plug assist forming lets factories use thinner plastic sheets. The parts stay strong but cost less and weigh less. The process also makes the finished product better.

Plug assist forming is great for food packaging and medical trays. It is also good for parts that need exact shapes. The method gives more control over the final product. It helps cut down on waste and makes work faster. Many industries use plug assist forming to meet high quality rules.

Tip: Plug assist forming is best when a company needs strong, detailed, and light parts from thermoforming.

Thermoforming uses different ways to shape plastic sheets. Each way has its own good points and best uses. The main types are vacuum forming, pressure forming, twin sheet forming, and plug assist forming.

The table below shows how vacuum forming, pressure forming, and twin sheet forming compare in cost and how many parts they can make:

| Method | Cost-Effectiveness | Scalability |

|---|---|---|

| Vacuum Forming | Lower tooling costs, suitable for small to large applications | Good for small-batch and large-format applications |

| Pressure Forming | More expensive but offers better detail, economical for mid-volume runs | Ideal for mid-volume runs of complex parts |

| Twin Sheet Forming | Higher tooling costs, produces strong, lightweight parts | Best for advanced applications with internal features |

Here is a short summary of each way:

Vacuum forming is easy and saves money. It works for small and big jobs.

Pressure forming costs more but gives better details. It is best for making medium amounts.

Twin sheet forming costs the most. It makes strong parts with special inside features.

Plug assist forming is special when a company needs exact parts and even thickness. It works with vacuum and pressure forming. This way helps factories make better products and save money. Picking the right thermoforming way depends on the part’s shape, size, and how many you need.

Manual machines are the simplest kind of thermoforming equipment. People do every step by hand. They put in the plastic sheet, heat it, and shape it over the mold. Workers also take out the finished part and cut off the extra edges. These machines cost less to buy at first. Many small shops and businesses use them for custom work or small jobs.

Manual thermoforming machines are best for easy shapes and small amounts. They are slow because people must do each step. This means not many parts get made each day. Over time, paying workers can cost a lot. Skilled workers are needed to keep the parts good.

Manual machines cost the least at the start.

They need more workers, so costs go up over time.

These machines are good for small jobs and simple work.

They are slow, so they are not good for big jobs.

Note: Manual thermoforming machines let companies start small and learn before using more advanced machines.

Semi-automatic machines are between manual and fully automatic ones. Some steps, like heating or shaping, are done by the machine. Workers still load and unload the plastic. They may also cut the finished parts by hand. This makes production faster than with manual machines.

Factories use semi-automatic thermoforming machines for medium-sized jobs. They can make more parts each hour than manual machines. These machines help make parts more the same and lower mistakes. But they still need workers, so labor costs are higher than with fully automatic machines.

Semi-automatic machines make twice as many parts as manual ones.

They cost more to run than manual, but less than fully automatic.

These machines give a good mix of speed and control.

They are good for companies that want to grow without spending too much.

Tip: Semi-automatic thermoforming machines help companies make more parts but still let workers control some steps.

Fully automatic machines do every step by themselves. They load, heat, shape, cool, and cut the plastic without help. These machines use smart controls and sensors to keep each part the same. They work fast and can run all day with little stopping.

Big factories pick fully automatic thermoforming machines for making lots of parts. These machines cost the most to buy and keep working. But they save money on workers and make more parts quickly. Fully automatic machines also make fewer mistakes and waste, so companies can meet high quality rules.

Fully automatic machines cost the most at first.

They lower worker costs and make parts faster.

These machines are best for big jobs.

They can run a long time without stopping much.

Fully automatic thermoforming machines help companies work their best and keep up with modern needs.

Thermoforming machines have two main types: inline and offline. Each type changes how factories make things and how good they are.

Inline thermoforming machines do every step in one line. The machine uses plastic sheets from a roll. It heats, shapes, cools, and trims the plastic. This setup helps factories work faster. They can make more parts quickly. Inline machines heat the plastic to the right temperature. Only the outside needs extra heat. This saves energy and time. The plastic moves smoothly through each step. This keeps the heat even. Every part looks the same.

Offline thermoforming machines work in a different way. Workers move the plastic sheets between machines. Sometimes, the plastic cools before the next step. Workers must heat the sheet again. This can waste energy. Roll changes and stops can cause problems. The plastic may not heat evenly. Finished parts may look different.

Factories pick inline machines for speed and quality. Inline machines keep the work steady. They help lower mistakes. Many companies use inline setups for food trays and cups. These products need to look the same.

Offline machines are good for small jobs or custom work. Workers can change the setup easily. This helps with special parts or new designs. But offline machines can slow things down. Reheating the plastic can make results uneven.

Here is a quick look at the main differences:

| Feature | Inline Thermoforming | Offline Thermoforming |

|---|---|---|

| Workflow | Continuous, fast | Interrupted, slower |

| Heating | Consistent, efficient | May need reheating |

| Output Quality | High, uniform | Can vary, less uniform |

| Best Use | Large runs, standard products | Small runs, custom products |

Inline machines keep heating steady, so work and parts are better.

Offline machines may have problems because of reheating and stops.

Inline machines heat the sheet well before shaping. Only the outside needs more heat.

Offline machines often stop for roll changes, which can hurt quality.

Tip: Factories that want fast work and good parts pick inline machines. Offline machines are best for special jobs or small batches.

Image Source: pexels

Thermoforming is very important for packaging. Many companies use it to make strong, light containers. Thermoforming machine makers build machines for many packaging types. These machines help companies make things fast and waste less. Thermoformed packaging keeps products safe during shipping. It also keeps them fresh in stores. Companies like this method because it saves money and is flexible.

Food packaging must keep food safe and fresh. Thermoforming machine makers make machines for trays, cups, and lids. These are used for dairy, snacks, and ready meals. Thermoforming lets companies use materials that block air and water. This helps food stay good longer. Many packages have tight seals and clear lids. This lets people see the food inside. Companies also make single-serve and multi-section trays. These help cut down on food waste and make things easier for buyers.

Medical packaging needs to be very safe. Thermoforming machine makers build machines for blister packs, trays, and clamshells. These keep medical items clean and safe from harm. Makers use special plastics that are safe for medicine. Thermoforming makes packages that are easy to open but keep things sterile. Hospitals and clinics use these to store and move medicine and tools. The process can make many shapes and sizes. This helps meet the needs of healthcare.

Thermoforming is used a lot in making car parts. Companies use it to make parts that are strong and light. Thermoforming machine makers provide machines for door panels, dashboards, glove boxes, and consoles. The table below lists some car parts and their good points:

| Component | Benefits |

|---|---|

| Door Panels | Make cars lighter, safe, and can be shaped in many ways. |

| Exterior Door Panels | No need to paint, light, and last a long time. |

| Instrument Panels | Can be made for airbags, light, and detailed. |

| Glove Boxes | Strong, look nice, easy to clean, good for car insides. |

| Center Consoles | Safe, can be made in many ways, and resist spills. |

Thermoforming lets companies make custom dashboards and bumpers. They can make parts faster than with other ways. It costs less to make tools for this process. Thermoforming heats plastic sheets until they are soft. Then, companies shape them over molds. This makes car parts work better and last longer.

Thermoforming machine makers help companies make many things people use. These include toys, sports gear, and furniture parts. Companies use thermoforming for RC cars, blocks, puzzles, and action figures. Sports gear like helmets and pads are made this way too. Furniture makers use it for chair arms, backs, and legs. The process makes toys that last a long time. Containers made this way often have tight lids to keep things fresh. Companies like thermoforming because it is fast and can make detailed shapes.

Tip: Using thermoforming for consumer goods helps companies make strong and good-looking products.

Thermoforming is used a lot in building. Builders like it because parts are strong and light. These parts help buildings last longer. They also need less fixing. Thermoforming machines shape plastic sheets. They make wall panels, roof insulation, and window trims. These things help keep buildings safe and comfy.

The table below shows how thermoforming helps builders:

| Application/Benefit | Description |

|---|---|

| Lightweight and Durable Components | Thermoformed plastics are light and tough. They last a long time and need little care. Builders use them for wall panels and roof insulation. |

| Customizable Designs | Thermoforming makes cool shapes and details. Builders can use it for curved walls and special window trims. |

| Enhanced Thermal and Acoustic Insulation | Thermoformed materials keep heat and sound in or out. This helps save energy and makes buildings quieter. |

| Improved Safety and Compliance | Thermoforming makes parts that do not burn easily. They are also strong and meet safety rules. |

| Cost-Effectiveness and Efficiency | The process saves money, especially for big parts. It helps builders spend less and finish faster. |

Builders use new ideas with thermoforming. Some add smart materials to their parts. Others use robots and 3D printing to work faster. Many builders use recycled plastic to help the planet. Modular building is getting popular. It lets workers build faster and waste less.

Tip: Thermoforming helps builders make safe and modern buildings. It also helps them use green materials.

Thermoforming is important for planes and military gear. Airplane makers use it for light and strong parts. These parts help planes use less fuel. They also let planes carry more people or things. Thermoforming machines make bins, cockpit panels, and trays for planes. Each part can be made special for its job.

The table below shows how thermoforming helps in aerospace and defense:

| Application Area | Description |

|---|---|

| Aerospace Interiors | Makes light and tough parts like bins and cockpit panels. |

| Customized Solutions | Makes special trays and storage for different plane cabins. |

| Prototyping | Makes test parts for new plane designs and layouts. |

| Defense Equipment | Makes strong covers for electronics and weapons. |

| Camouflage Components | Makes plastic parts that help hide military gear outside. |

Thermoforming lets engineers make custom parts fast. They can test new ideas and change designs quickly. Defense companies use it to protect important gear. The process makes covers that keep electronics safe. It also helps make parts that hide military stuff in nature.

Thermoforming makes light, custom parts for planes and military vehicles.

It helps test new designs quickly.

The process gives strong protection for defense gear.

Many companies do better work with thermoforming machines. These stories show how thermoforming helps them work faster and better.

| Case Study Title | Key Impact | Link |

|---|---|---|

| More Parts, Less Labor | Automation solutions for part removal, improving labor efficiency | More Parts, Less Labor |

| ILLIG Dynamic Process Optimization | Enhanced production speed and reduced scrap rates | ILLIG Dynamic Process Optimization |

| Old Tool + New Machine = Faster Production | Average cycle rate increase of nearly 50% | Old Tool + New Machine = Faster Production |

| Upgrading Food Packaging Thermoforming Lines | Reduced oven length and increased cycles per minute by 50% | Upgrading Food Packaging Thermoforming Lines |

One company used robots with thermoforming to take out parts faster. This helped them use fewer workers and save money. Another company made more parts with less waste. Some factories used new machines with old tools. They made parts almost twice as fast. Food companies made more packages in less time. They also used less energy.

Note: These examples show how thermoforming helps companies work smarter and faster.

Automation has made big changes in thermoforming. Companies use new technology to make machines work faster and smarter. Automated thermoforming machines can run all day without stopping. This helps factories make more parts with less work. Now, one person can watch over many machines at once. This means factories need fewer workers and spend less money on labor. During the pandemic, companies used more automation to keep up with orders and follow safety rules.

Here are some ways automation helps factories:

| Benefit | Description |

|---|---|

| Increased Throughput | Automated systems work all the time, so factories make more parts. |

| Consistency | Automation makes sure every step is done the same way, so products are better. |

| Labor Savings | Fewer workers are needed, so mistakes and costs go down. |

One person can now run more than one machine.

Automation helps factories make more parts and keep them good.

The thermoforming industry uses automation to stay ahead.

Digital integration brings smart technology into thermoforming. Factories use sensors, data tools, and smart controls. These help machines work better and last longer. Workers can watch machines in real time and fix problems before they stop work. Predictive maintenance keeps machines running and saves money on repairs. AI and machine learning check each part to make sure it is good.

Some important trends in digital integration are:

Using AI and machine learning to check quality automatically.

Predictive maintenance helps machines work better for longer.

Real-time process changes make production faster.

Sensors and data tools help plan repairs before things break.

Machines can be changed quickly for new materials.

IoT and Industry 4.0 make machines work even better.

Digital integration helps factories save time and money. It also makes production faster and more flexible.

Sustainability is very important in thermoforming. Companies want to help the planet and use resources wisely. Many pick materials that are better for the environment. Polypropylene, HMWPE, ABS, polycarbonate, and PVC are strong, can be recycled, and use less energy to make. Some factories use recycled materials from old products or other factories. This helps cut down on waste and saves resources.

Some ways factories use sustainable practices are:

Picking materials that make less pollution.

Recycling plastics so they do not end up in landfills.

Using less energy and making less greenhouse gas.

Showing they care about the environment.

Sustainability helps companies follow new rules and attract people who care about the earth. The thermoforming industry leads by using green materials and better ways to make things.

Modern thermoforming machines use new tech to save energy and money. Factories want to use less power and make more things. Old machines wasted heat and used more electricity. New machines fix this with smart features. Many machines have better heating systems now. Infrared heaters warm plastic sheets fast and evenly. This means the machine uses less energy but stays hot enough. Good insulation helps keep heat inside the machine. Less heat escapes, so less energy is wasted. Automation is important too. Automated controls stop machines from running when not needed. This helps factories use energy only when they need it.

Here is a table that shows how new thermoforming machines save energy compared to old ones:

| Feature | Description |

|---|---|

| Advanced Heating Systems | Infrared heaters use less energy and keep heat steady. |

| Automation | Automated features cut down on wasted time and save power. |

| Insulation | Good insulation keeps heat in and lowers energy use. |

Factories also use CNC control systems for better accuracy. Servo-driven actuators move parts faster and more exactly. These features help the machine use less power for each part. Energy-saving heating elements and smart sensors help too. They make sure the machine only uses the energy it needs.

Tip: Picking a thermoforming machine with energy-saving features helps companies spend less and protect the planet.

Quality control is very important in thermoforming. Factories want every part to be just right. New machines use special tools to check each product. Laser scanning and measuring tools check size and shape without touching. These tools help make sure every part matches the plan. Infrared thermography checks the heat during warming. This keeps the plastic at the right temperature, so fewer mistakes happen. Automated vision systems use cameras to look for surface problems or wrong sizes. These systems find mistakes fast, so workers can fix them quickly. Thickness gauges and ultrasonic testing tools check if the plastic is the same thickness everywhere. This is important for strong and safe parts. Special software watches the whole process in real time. It finds problems early and helps keep quality steady.

Here are some key quality control technologies in modern thermoforming:

Laser scanning and measuring tools for checking size.

Infrared thermography to watch heating and stop mistakes.

Automated vision systems to spot surface and size problems.

Thickness gauges and ultrasonic testing for even parts.

Special software for real-time checks.

Note: Good quality control in thermoforming means safer, stronger, and more reliable products for everyone.

Picking the right thermoforming machine is very important. It helps a company make better products and save money. The right choice also makes work go smoothly.

There are many things to think about when choosing a machine. Each one matters for how well the machine works for the company.

| Decision Factor | Description |

|---|---|

| Production Volume | Choose between manual/semi-automatic for low volume or fully automated for high volume. |

| Material Compatibility | Ensure the machine can handle specific thermoplastics like ABS, PETG, or polypropylene. |

| Product Size and Complexity | Larger forming areas and advanced controls are needed for complex and large parts. |

| Precision Requirements | Machines with advanced pressure forming or multi-axis capabilities are ideal for fine details. |

| Cost Considerations | Evaluate initial investment, maintenance costs, and energy efficiency for long-term savings. |

Production volume helps decide which machine to buy. Small shops use manual or semi-automatic machines for short jobs. Big factories need fully automatic machines for lots of work. High-volume machines make more parts and need fewer workers.

Material compatibility is important for strong products. Some machines work best with certain plastics like ABS, PETG, or polypropylene. Companies must check if the machine can use the right materials. Using the right plastic makes parts safe and tough.

Precision needs help pick the best machine. Products with small details need special machines. These machines use advanced pressure forming or multi-axis controls. They help make sharp edges and smooth surfaces. High-precision machines make sure every part is just right.

Budget and return on investment (ROI) are big factors. Companies look at the price, upkeep, and energy use. Machines that save energy cost less over time. A smart buy means good quality and saving money in the long run.

Vendor support helps keep machines working well. Good vendors give:

Fast help when there are problems

Choices to change machine features

Clear instructions and training

Payment plans or leasing options

Experience helping companies like yours

Good vendor support means less waiting and quick fixes. Training helps workers use machines safely and well.

Customization lets companies get machines that fit their needs. Vendors offer different sizes and features. For example, a big vacuum forming machine (84" x 108") makes large parts. A single station vacuum former (48" x 72") is good for smaller jobs. Pressure formers make parts with more detail.

| Machine Type | Description |

|---|---|

| 84" x 108" | Large vacuum forming machine for extensive applications. |

| Three station rotary vacuum former | Allows for efficient production with multiple stations. |

| 48" x 72" single station vacuum former | Versatile for smaller parts and simpler designs. |

| 48" x 72" single station pressure former | Ideal for parts requiring more detail and tighter tolerances. |

| Thermoplastic Material Options | Various materials available to meet industry standards and specific needs. |

Customization gives other good things too:

Lower tool costs than injection molding

Faster times for making new parts

Flexible designs with many colors and textures

Can make big and complex parts

Tip: Companies that pick machines with the right features and help do better and work faster.

MAAC Machinery is a top company in North America. They make advanced thermoforming machines for many industries. These include automotive, aerospace, and packaging. MAAC builds rotary, single-station, and twin-sheet pressure formers. Their machines help factories make big and tricky plastic parts. The parts come out with high precision.

In 2025, MAAC Machinery has several main models. Each model has special features for different jobs.

| Model | Key Features |

|---|---|

| 2025 MAAC Model C106R3 | New 10’x6’ Three Station Rotary for high-volume production |

| 2025 MAAC Model ASP | 36” x 30” Single Station, ready for immediate delivery |

| 2025 MAAC Model C64SPT | 6’x4’ Single Station Twin Sheet Pressure Former for strong, hollow parts |

| 2025 MAAC Model C44SPTO | 4’x4’ Single Station Twin Sheet Pressure Former for smaller runs |

MAAC Machinery is known for custom solutions. They help customers pick the best machine for their needs. Many factories trust MAAC for reliable machines and good support.

Tip: MAAC Machinery’s rotary and twin-sheet machines are great for making big, complex parts for cars and planes.

GABLER Thermoform is a top company in the world. They build high-quality machines in Germany. GABLER focuses on making machines that are exact and dependable. Their machines help factories make food packaging, trays, and cups. The shapes and sizes are always correct.

GABLER Thermoform offers flexible and fast machines. They listen to what customers need and give good solutions. GABLER’s machines use smart controls and automation. This helps factories work faster and waste less material. Their strong reputation makes them a favorite for companies everywhere.

Note: GABLER Thermoform’s machines are famous for German engineering and great results in food packaging.

Asano Laboratories is a well-known company in Japan. They have built reliable machines for a long time. Their machines are used for packaging, electronics, and car parts. Asano Laboratories works hard on research and development. Their engineers design machines that meet strict quality rules.

Factories in Asia and other places use Asano’s machines for small and big jobs. The company gives good support and training after sales. Asano Laboratories helps customers work better and make higher quality products with each new machine.

Asano Laboratories is known for new ideas and careful design. This makes them a trusted partner for companies in Japan and around the world.

Qingdao Xinbeneng Equipment is a top company in China. They make thermoforming machines that work fast and save energy. Many factories use Xinbeneng’s machines to make food trays and cups. These machines also make containers for packaging.

The main model for 2025 is the XBN-760A Fully Automatic Thermoforming Machine. This machine uses servo motors to move quickly and exactly. It can form, cut, and stack products all in one line. The machine works with many plastics like PP, PET, and PS. Xinbeneng’s engineers made the machine to use less energy and make less waste.

| Model | Key Features |

|---|---|

| XBN-760A | Fully automatic, servo-driven, high-speed forming |

| XBN-680A | Compact design, easy to use, quick mold change |

| XBN-1080A | Large forming area, for big packaging products |

Xinbeneng gives good help after you buy a machine. They train workers and send spare parts fast. Many customers pick Xinbeneng because the price is good and the machines work well.

Note: Xinbeneng’s machines help factories make safe and clean packages for food and medicine in fast-growing places.

COMI SpA is a famous company from Italy. They make advanced thermoforming machines. The company started in 1973 and now sells machines in many countries. COMI’s machines help make car parts, fridge doors, and packaging.

The COMI FPL Series is the main line for 2025. These machines have strong frames and controls that are very exact. The FPL Series works with thick and thin plastic sheets. COMI’s engineers use CNC technology for better accuracy. The machines can make big and tricky parts like car bumpers and fridge doors.

| Model | Main Application | Special Features |

|---|---|---|

| FPL Series | Automotive, appliances | CNC controls, large forming area |

| EIDOS Series | Packaging, technical parts | Fast cycle times, energy saving |

| VERTICAL Series | Aerospace, special parts | Vertical forming, high precision |

COMI SpA makes custom machines for special jobs. They work with customers to design what is needed. COMI also cares about saving energy and keeping workers safe.

COMI’s machines use less power.

They follow strict safety rules in Europe.

The company gives training and quick service.

Tip: COMI SpA is a smart pick for companies that need custom machines for big and tricky parts.

Sencorp is a big company in America. They make thermoforming machines and have over 70 years of experience. Sencorp’s machines are used for packaging, medical, and consumer goods.

The main model for 2025 is the Sencorp Ultra Thermoformer. This machine has advanced controls for fast and exact forming. It can make detailed parts with tight sizes. The Ultra Thermoformer works with many plastics like PET, PVC, and HIPS.

| Model | Key Features |

|---|---|

| Ultra Thermoformer | High-speed, precise, for medical packaging |

| 2500 Series | Flexible, for food and consumer packaging |

| 2500X Series | Extra-large forming area, for big products |

Sencorp helps customers with training and spare parts. They also give remote help when needed. Many factories trust Sencorp because their machines last long and work well.

Sencorp’s machines help companies meet strict quality rules.

The company is a leader in medical and food packaging.

Sencorp uses new technology to save energy.

Sencorp’s focus on quality and support makes it a trusted partner for many American companies.

Erkopress Motion is a top company in Germany. They make machines for dental, medical, and technical parts. Their machines use smart controls and automation. This helps factories work faster and better. The main model for 2025 is the Erkopress Motion 3D. It has digital pressure control and smart sensors. Workers can set the right pressure and temperature for each job. The machine shapes plastic sheets into detailed forms. It works with many materials like PETG and PVC.

| Model | Key Features |

|---|---|

| Erkopress Motion 3D | Digital pressure control, 3D forming, fast cycles |

| Erkopress TC | Touchscreen controls, easy setup, compact size |

| Erkopress ES | Energy-saving, quiet operation, for small batches |

Factories use Erkopress Motion machines for dental trays and medical packaging. They also use them for technical covers. These machines help workers make parts with even thickness. The surfaces come out smooth. The company gives training and support to help customers. This helps people use the machines well.

Tip: Erkopress Motion machines are best for jobs that need exact shapes and clean results.

Brown Machine Group is a leading company in the United States. They have made strong thermoforming machines for many years. Brown Machine Group helps industries like packaging, food, and cars. The main model for 2025 is the Brown BMG-Cut Series. This machine uses servo-driven technology for fast forming. It can form, cut, and stack products in one line. Workers use a touchscreen to control the machine. It works with plastics like PP, PET, and PS.

| Model | Main Application | Special Features |

|---|---|---|

| BMG-Cut Series | Food packaging, trays | Servo-driven, inline forming and cutting |

| BMG-Flex Series | Automotive, consumer goods | Flexible setup, quick mold change |

| BMG-Stack Series | Medical packaging | High-speed stacking, precise trimming |

Brown Machine Group helps factories make more parts with less waste. The company gives remote support and sends spare parts quickly. Many customers pick Brown Machine Group for strong machines and good service. Their machines help companies follow safety and quality rules. The company uses new technology to save energy and work faster. Brown Machine Group trains customers and gives technical help.

Note: Brown Machine Group is a good choice for factories that want fast and reliable thermoforming solutions.

Kiefel is a global leader in thermoforming technology. They build machines for packaging, medical, and car industries. Kiefel works on new ideas and cares about the environment. Their machines help factories make good products and use less energy. The main model for 2025 is the Kiefel KMD 78.2 Speed. It uses advanced heating and forming systems. Workers can change settings for different materials and shapes. The KMD 78.2 Speed forms, cuts, and stacks products quickly. It works with plastics like PET, PP, and PLA.

| Model | Key Features |

|---|---|

| KMD 78.2 Speed | High-speed forming, energy-saving, flexible setup |

| KMD 64.2 Premium | Precise forming, quick changeover, smart controls |

| KMD 52.1 Eco | Eco-friendly, low energy use, compact design |

Kiefel machines help factories save money and make better parts. The company gives digital tools for real-time monitoring. They also help control the process. Kiefel trains customers and gives service all over the world. Their machines use less energy and make less waste. Kiefel leads in smart controls and digital integration. They help customers follow new green rules.

Tip: Kiefel machines are great for companies that want fast, flexible, and eco-friendly thermoforming solutions.

Illig Maschinenbau is a top company in thermoforming. It started in Germany and is known for good quality and new ideas. Illig makes machines with the newest technology. Their machines shape plastic sheets into many forms. Factories use Illig machines for packaging, trays, and technical parts.

Illig cares about making things exact and saving energy. Their machines use smart controls to use less power and make less waste. The Illig IC-RD series is a main model for 2025. It works fast and makes parts very accurately. This machine can use many kinds of plastic. It lets factories switch jobs quickly, so they can do more.

Some important features of Illig Maschinenbau machines are:

Advanced heating systems help shape plastic evenly.

Automated controls make better parts and less waste.

Fast mold change systems save time for workers.

Energy-saving designs help companies spend less money.

Many companies pick Illig because the machines last for years. Illig gives good customer support and teaches workers how to use the machines. Illig helps factories follow strict quality rules and make their work better.

Illig Maschinenbau mixes German engineering with new ideas. Their machines help companies work smarter and care for the planet.

The best thermoforming machine makers in 2025 all have special strengths. Some use the newest technology. Others are great at helping customers or saving money. The table below shows how these companies are different:

| Manufacturer | Strengths | Weaknesses |

|---|---|---|

| Illig Maschinenbau (Germany) | Cutting-edge technology, precision, energy efficiency | N/A |

| Kiefel Technologies (Germany) | Innovation, sustainability | N/A |

| Multivac (Germany) | Reliability, advanced automation | N/A |

| TZ Machinery (China) | Cost-effective, strong R&D, customer satisfaction | N/A |

| GABLER Thermoform (Germany) | Sustainability, efficiency | N/A |

| Asano Laboratories (Japan) | Precision, durability | N/A |

| GEISS AG (Germany) | High-speed, productivity | N/A |

| Qingdao Xinbeneng Equipment (China) | Affordability, reliability | N/A |

| COMI SpA (Italy) | Flexibility, complex design handling | N/A |

| Brown Machine Group (USA) | Innovation, customer support | N/A |

Each company is good at something different:

Illig Maschinenbau and Kiefel Technologies are best at new technology and caring for the environment.

Multivac and GEISS AG are known for making reliable and fast machines.

TZ Machinery and Qingdao Xinbeneng Equipment help companies save money.

GABLER Thermoform and COMI SpA are great at making efficient machines and flexible designs.

Asano Laboratories is famous for making exact and tough machines.

Brown Machine Group is known for helping customers and bringing new ideas.

Companies should pick a manufacturer that fits what they need. Some want fast machines. Others want to save energy or get good help. Picking the right company helps factories make better products and stay ahead.

Thermoforming machines keep changing with new technology. Companies use automation and digital tools to work faster. Many factories add sensors and smart controls to their machines. These upgrades help workers check quality and fix problems quickly. Factories also use eco-friendly materials to help the planet. New plastics can be recycled or break down safely. The market for thermoforming machines is growing. Food, healthcare, and car industries need more products.

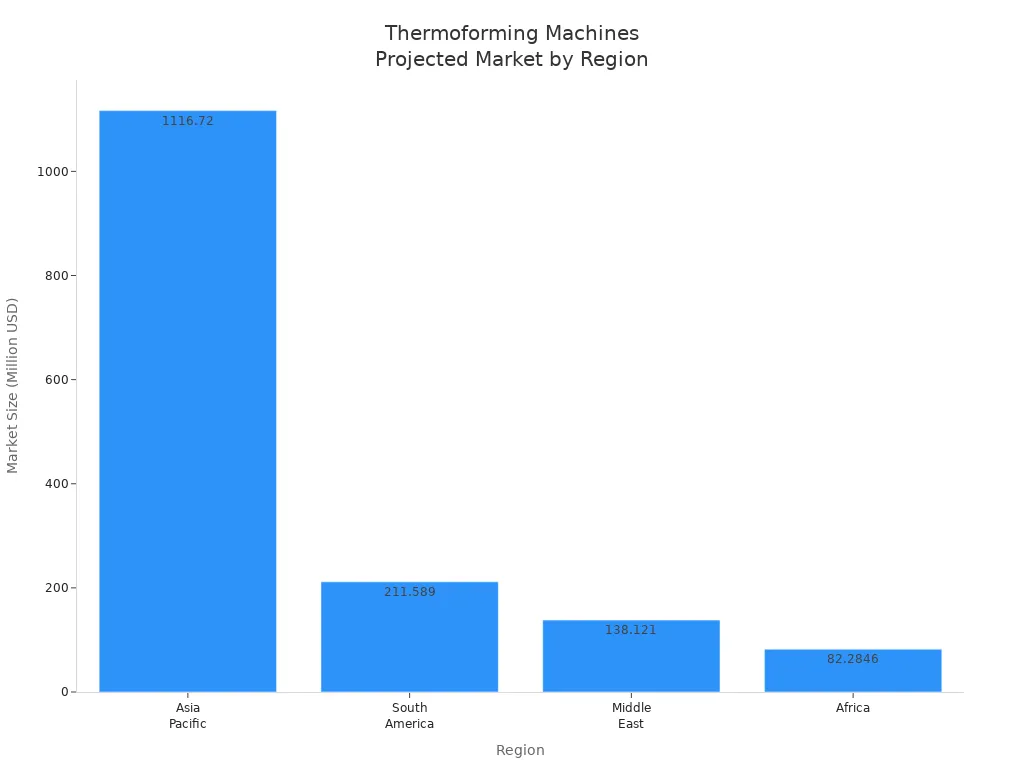

The table below shows how the market will grow in different regions by 2033:

| Region | Market Share (%) | Growth (2021-2025) | Projected Market (2033) | CAGR (%) |

|---|---|---|---|---|

| Asia Pacific | 36.20% | 82.69% | 1116.72 Million USD | 5.357% |

| South America | 7.10% | 71.44% | 211.589 Million USD | 4.903% |

| Middle East | 5.20% | 83.15% | 138.121 Million USD | 3.405% |

| Africa | 3.00% | 77.61% | 82.2846 Million USD | 3.821% |

Factories in Asia Pacific lead with new machines and smart tech. They invest in green solutions and better equipment. South America, the Middle East, and Africa also grow fast. These places build more factories and use improved machines.

Many new places now use thermoforming machines. Asia Pacific grows quickly because people buy more packaged food and cars. South America and Africa build more factories too. These regions want machines that work fast and save energy. Companies there look for machines that use less power and make less waste.

Factories in these areas use digital tools to track production. They pick machines that work with recycled plastics. Many companies train workers to use new technology. This helps them make better products and grow their business.

New markets help the thermoforming industry grow. They bring fresh ideas and create more jobs.

Thermoforming faces some problems as it gets bigger. Factories must follow new safety and environment rules. Some places have strict laws about recycling and waste. Companies need to use less energy and make cleaner products. Workers must learn new skills for advanced machines.

Factories also compete with other ways to make plastic parts. Injection molding and 3D printing offer different benefits. Thermoforming must stay flexible and improve quality to keep up. Supply chain problems can slow down production. Companies must plan for changes in material prices and shipping delays.

Factories need to train workers for new machines.

Companies must follow new safety and recycling rules.

Supply chain issues may affect production speed.

⚠️ Staying ahead means using smart technology, caring for the planet, and helping workers learn new skills.

Industrial thermoforming machines help factories make things faster. They also help factories make better products. These machines bring new ideas to how things are made. Many industries use them for different jobs. Companies that learn about new technology do better. Picking good partners helps them stay ahead.

Learning about the newest changes gives companies a big advantage. Thermoforming will keep changing how things are made around the world as more places use it and smarter ways are found.

Factories use plastics like ABS, PET, PVC, and polypropylene. These plastics get soft when heated and keep their shape after cooling. Some companies pick recycled or biodegradable plastics to help the environment.

Automation lets machines work faster and more exactly. Workers do not need to do as many steps by hand. Factories make more parts with fewer errors. Automated systems also help save money on workers.

Thermoforming machines can make both easy and hard shapes. Pressure forming and plug assist forming help make parts with lots of detail. Factories pick the best way based on what the product needs.

Thermoforming is used a lot for packaging, cars, medical items, and things people buy. Construction companies use it too. Aerospace and defense companies use these machines for light and strong parts.

Factories use digital controls and smart sensors to watch how things are made. They recycle leftover plastic and pick materials that make less waste. Some companies use AI to help work better.

Modern machines have emergency stop buttons, safety covers, and sensors. These features help keep workers safe from harm. Training teaches workers how to use machines safely.

Companies think about how many parts they need, what plastic to use, how big the parts are, and how much money they have. They also look at help from the seller and if the machine can be changed for their needs. The right machine helps factories reach their goals.

Thermoforming can be good for the environment. Factories use recycled plastics and machines that save energy. Some companies use biodegradable plastics to help protect nature.