Views: 0 Author: Site Editor Publish Time: 2025-09-08 Origin: Site

Plastic thermoforming machines have changed manufacturing by making it faster and cheaper. Many factories now use new technology like automation and robotics. This helps them make things quicker and with fewer mistakes. Rapid prototyping lets manufacturers change their products fast when needed. Industries like food, automotive, and packaging use modular equipment. This equipment is easy to customize for different jobs. These changes help protect products better. They also mean workers do less hard work and products are higher quality.

Plastic thermoforming machines help make things faster. They also help save money. This makes manufacturing work better.

Automation and robotics in thermoforming help make things more exact. They also help stop mistakes. This means products are better.

The thermoforming process uses most of the plastic sheets. It uses over 90%. This helps cut down on waste. It also helps the environment.

Rapid prototyping lets makers change designs fast. They can meet new market needs quickly.

Using sustainable materials in thermoforming helps the planet. It helps companies lower their carbon footprint.

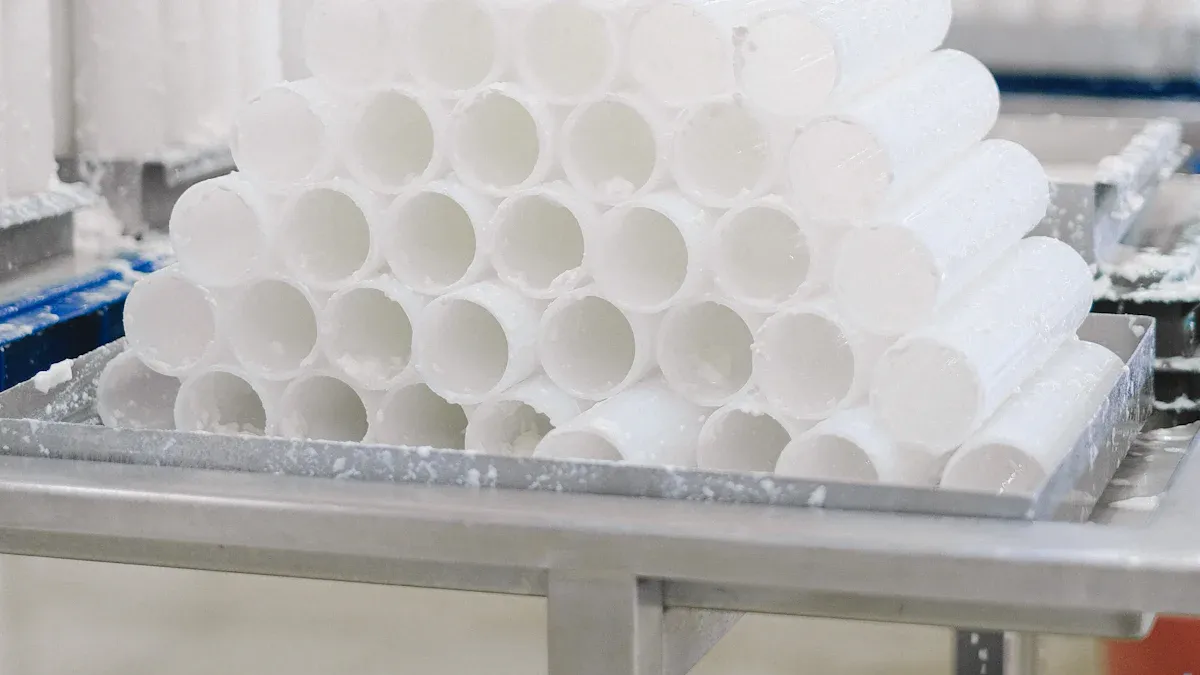

Image Source: unsplash

Thermoforming is a way to shape plastic sheets into products. Factories use plastic thermoforming machines to heat a flat sheet until it gets soft. Then, workers or robots put the sheet over a mold. The machine uses vacuum or pressure to make the plastic fit the mold. When the plastic cools, it keeps its new shape.

Plastic thermoforming machines are popular because they work fast and use less energy than older ways. These machines can make many things, like food containers and car parts. They help companies save money and throw away less plastic. The process uses more than 90% of each plastic sheet, so there is less waste. Thermoforming is the best way to make big plastic parts with less energy. The products are light and easy to recycle, which is good for the environment.

Here is a table that shows why plastic thermoforming machines work better than older methods:

| Evidence Type | Description |

|---|---|

| Lower Tooling Costs | Thermoforming molds use aluminum, which costs less than steel molds for injection molding. |

| Faster Lead Times | Simple mold designs allow for quick changes and rapid prototyping. |

| High Material Yield | Over 90% of the plastic sheet is used, reducing waste. |

| Thermal Efficiency | Aluminum molds heat and cool quickly, saving energy. |

| Shorter Cycle Times | Each part takes less time to make compared to injection molding. |

| Automation | Machines often use robots for handling and trimming, making production faster and more reliable. |

| Scalability | Factories can make small or large batches without big cost increases. |

| Cost Efficiency | Large parts cost about half as much and take less time to produce than with other methods. |

Tip: Thermoforming works for small custom jobs and big production runs. This helps many industries change quickly when they need to.

The thermoforming process has a few clear steps. Each step uses new technology to make sure the product is strong and accurate.

Sheet Heating: The machine heats a flat plastic sheet to a set temperature. The heat makes the plastic soft and easy to shape.

Molding: The soft plastic moves to a mold. The machine uses vacuum or pressure to press the plastic against the mold’s surface.

Cooling/Trimming: The plastic cools quickly, which makes it hard again. Workers or robots trim away any extra material.

The science in each step includes:

Thermal Expansion: Heating makes the plastic expand and bend.

Pressure Application: Vacuum or force shapes the plastic.

Heat Transfer: Cooling makes the plastic solid again.

Factories use sensors and controls to keep the process steady. This helps stop problems like uneven heating or weak spots. Here are some common problems and ways to fix them:

| Challenge | Causes | Solutions |

|---|---|---|

| Inconsistent Sheet Heating | Uneven heat, wrong temperature, wrong thickness | Calibrate heaters, use sensors, adjust heating time |

| Sheet Distortion During Forming | Uneven heating, bad mold design, wrong pressure | Use correct heating, improve mold design, monitor pressure |

| Thin or Weak Spots | Uneven heating, weak vacuum, wrong material | Adjust heating, use strong vacuum, follow material guidelines |

| Inaccurate Part Dimensions | Bad mold setup, uneven heating, wrong cooling time | Align molds, adjust heating, change cooling time |

| Molded Part Surface Defects | Dirty material, uneven heating, bad cooling | Clean materials, heat evenly, cool properly |

| Material Shrinkage or Expansion | Expansion, moisture | Choose right material, control storage, plan for shrinkage |

| Warping After Cooling | Uneven cooling, stress, wrong material | Cool evenly, reduce stretching, pick warp-resistant materials |

| Burn Marks or Scorching | Overheating, hot surfaces, too much heat | Watch heating cycles, adjust mold temperature, heat evenly |

Advanced plastic thermoforming machines use robots and computers to fix these problems. These features help every product look the same and cut down on waste. The machines also let factories switch between products quickly, which saves time and money.

Factories use automation in thermoforming to work faster. Machines now do jobs people did before. This helps companies make more products in less time. New tools like Model Predictive Control help machines control heat better. Deep Reinforcement Learning lets machines fix problems before they start. Machines can change heater power by themselves. This keeps the plastic at the right temperature. Products turn out better and there are fewer mistakes.

Digital tools like IoT let workers watch machines live. Industry 4.0 helps them see problems right away. They can fix things fast and keep work going. This means less downtime and more products made. Automated systems help companies save money. Machines can run longer without stopping. Factories need fewer workers on the floor. Some companies say automation lets them make more with less manpower. They also see fewer errors and less waste.

Note: Automation in thermoforming helps factories go faster and make better products. It also lowers labor costs and keeps machines working longer.

Thermoforming uses computer tools to design and make products. CAD lets engineers draw and test ideas on a screen. AI helps these tools work even better. AI-powered CAD systems make designs more accurate. They help create new products quickly. Companies can bring new items to market faster.

AI helps machines find problems early. Engineers use simulation tools to test products before making them. This helps them fix mistakes early. It saves time and money. Tools like PAM-COMPOSITES let engineers try different settings. They do not need to make real parts. This makes the process safer and cheaper.

CAD and AI help find defects early in development.

Engineers can change settings to avoid costly changes later.

Simulation tools like PAM-COMPOSITES let them test ideas fast and cheap.

AI also helps with predictive maintenance. Machines can warn workers before they break down. This keeps machines running and cuts downtime. Companies using these tools see fewer mistakes and lower costs. They need fewer workers to check each part. This means products are more consistent and factories work better.

Some companies say automation helps them make products faster and in bigger amounts. This can lower labor costs because machines stop less.

Automation lets machines run longer and need fewer workers, which saves money.

Thermoforming has changed a lot with these new tools. Factories use new technology to make better products faster. They save money and use less energy. These changes help companies stay ahead in a fast market.

Image Source: pexels

The thermoforming industry is very important for packaging. Companies use thermoforming to make blister packs, clamshells, trays, and containers. These items keep food, electronics, and medicines safe. Vacuum packaging is the most common and makes up 45% of the market. Food and beverage companies use vacuum packaging the most. Pressure packaging is 30% of the market and is growing fast in medicine and cosmetics. Mechanical packaging is the rest and keeps getting bigger.

Note: Food and beverage packaging is 40% of the market. Pharmaceuticals are next at 25% and are growing faster than other areas.

Manufacturers must follow strict rules to keep food and medicine safe. They use food-grade materials and follow FDA rules. Labels must show important facts. Companies also track materials to make sure they are safe.

| Regulatory Aspect | Description |

|---|---|

| FDA Regulations | Makes sure food packaging is safe. |

| Material Selection | Needs food-grade materials to stop contamination. |

| Labeling Requirements | Gives consumers facts and meets the law. |

| Traceability | Tracks materials to check for safety. |

| Quality Management | Keeps products safe by following standards. |

The thermoforming industry helps the automotive and medical fields in many ways. Car makers use thermoforming for dashboards, door panels, bumpers, and spoilers. These parts are light and help cars use less fuel. In medicine, companies make trays, device housings, and disposable items. Cleanrooms are important for medical products. They help meet strict safety rules for surgical trays and orthopedic kits.

Cleanrooms like ISO Class 8 keep parts clean and accurate.

Quality checks like Installation Qualification, Operational Qualification, and Performance Qualification make sure medical devices are safe.

Tip: Thermoforming lets companies change designs quickly. This helps the automotive and medical industries keep up with new needs.

Thermoforming gives many benefits to consumer products. Companies use it to make household items, electronics cases, and sports equipment. These products are strong, light, and easy to shape. Thermoforming also helps make retail displays and product cases that look nice and protect things.

| Example | Advantages |

|---|---|

| Automotive Components | Light and strong, helps cars use less fuel. |

| Medical Devices | Accurate and easy to customize for trays and covers. |

| Packaging Solutions | Protects items and cuts down on waste. |

| Consumer Goods | Good for displays and cases, makes products look better. |

| Aerospace Components | Strong and light, helps planes work better. |

| Agricultural Equipment | Custom parts help machines work and stay safe. |

The thermoforming industry keeps growing as more companies find new uses. Its many uses help different industries work faster and smarter.

Manufacturers now care more about using sustainable materials. They want to make thermoforming better for the environment. They use post-consumer recycled plastics, bioplastics, recyclable thermoplastics, and natural fiber composites. These materials help cut down on landfill waste. They also lower carbon emissions. Companies encourage recycling in their factories. Lighter thermoformed parts mean trucks use less fuel. This helps vehicles save energy. These changes support green and energy-saving ways to make things.

| Sustainable Material Type | Description | Use Cases |

|---|---|---|

| Post-Consumer Recycled Plastics (PCR) | Uses plastic waste from consumers to make new products. | Bakery trays, produce containers, clamshells |

| Bioplastics (PLA, PHA) | Comes from renewable sources and can compost in certain conditions. | Food packaging, disposable items |

| Recyclable Thermoplastics | Can be reprocessed and accepted by recycling programs. | Durable packaging, industrial trays |

| Natural Fiber Composites | Mixes plastic with biodegradable fillers to cut plastic content. | Specialty packaging, sustainable products |

Plastics like polypropylene, polycarbonate, PVC, HMWPE, and ABS are also recyclable and strong. These materials help companies reach their green goals. They also help lower harm to the environment.

Companies that pick sustainable materials lead the way in eco-friendly ideas and smart production.

Rapid prototyping has changed how new products are made. Now, manufacturers can make and test designs very quickly. They do this before making lots of products. Engineers can change shapes and features fast and with care. Factories use CAD and simulation tools to find problems early. This helps them avoid big mistakes and work better. Rapid prototyping also helps the planet by using less material and saving resources.

Engineers try out ideas quickly.

Factories waste less material.

Products get to stores faster.

DynamicMold technology is a new idea for custom thermoforming. It lets machines put watermarks right on products. Manufacturers use this to add special marks for tracking and stopping fakes. DynamicMold works with thermoforming, injection molding, and blow molding. Stores and customers can track products better and see digital date stamps. This technology makes it easier to change what is made. It also helps the industry be more green.

| Feature | Description |

|---|---|

| Technology | DynamicMold enables watermarking in forming machines. |

| Supported Techniques | Works with thermoforming, injection molding, and blow molding. |

| Benefits for Manufacturers | Adds traceability, anticounterfeiting, and digital date stamping. |

| Target Users | Helps manufacturers, retailers, networks, and customers. |

New ideas in custom thermoforming help companies keep up with market changes and make better products.

Plastic thermoforming machines help factories work faster. They also help factories change to new jobs quickly. The 3-station machines heat, form, and trim at the same time. This means there are no slow spots in the process. Production moves faster because of this setup. Automation does many jobs that people used to do. Machines can switch between products fast. This gives factories more choices. Companies can change machines for different sheet sizes and materials. They can make many products without stopping for long.

Heating, forming, and trimming happen together to save time.

Automation helps machines switch products quickly.

Custom machines work with many sizes and materials.

These things help factories work better. They also help companies meet what customers want.

Thermoforming saves money for many businesses. It costs less to start than injection molding. This is good for small and medium jobs. Tooling for thermoforming costs from $5,000 to $50,000. Injection molding can cost $20,000 to $150,000 or more. Startups and new products like the lower cost. They can use their money for other things and avoid big bills.

Thermoforming also makes parts faster than other ways. Factories can make lots of plastic parts quickly. This lowers labor costs and helps work go smoothly. For very big jobs, injection molding might be cheaper later. But thermoforming is still best for many who want to save money and stay flexible.

New thermoforming machines help companies make products the same every time. Automation stops mistakes and keeps quality high. Control systems shape materials just right. Smart manufacturing uses data to fix problems fast. Better cooling helps machines work well and makes better products.

| Feature | Benefit |

|---|---|

| Automation | Fewer mistakes, more products are the same. |

| Precision Control | Shapes materials the right way each time. |

| Material Handling | Works with many kinds of materials. |

| Reduced Defects | Makes better products with fewer problems. |

| Smart Manufacturing | Uses data to make quick changes. |

| Improved Cooling | Helps machines work faster and better. |

Quality checks are very important in this industry. Companies look at raw materials for thickness, strength, color, and clarity. They watch the temperature when heating. They check molds often. They control pressure, forming time, and cooling to stop problems. Careful trimming keeps products looking good and working well.

Making the same good products helps companies build trust and meet tough rules.

The thermoforming industry is getting bigger every year. In 2023, the global market for thermoforming plastics was about $14.4 billion. Experts think it will reach $20.1 billion by 2030. This means the market will grow about 5% each year. Many things help this growth happen:

More people want packaging that can be recycled and is better for the planet.

New machines and tools help factories work faster and make better products.

Healthcare and car companies use more thermoformed products now.

Thermoformed plastics are taking the place of metal parts in many jobs.

More food delivery and ready-to-eat meals need extra packaging.

The industry is also growing because medical companies use more antibacterial packaging. People want products that are safe and clean. More food processing and medical packaging also help the market get bigger.

The future for the thermoforming industry looks very good. New technology will change how companies make their products. The table below shows some big trends and what experts think will happen:

| Market Shift | 2020 to 2024 Trends | 2025 to 2035 Projections |

|---|---|---|

| Technological Innovation | Servo-driven systems, multi-station machines, inline trimming | AI-assisted forming, modular molds, low-energy thermoforming |

| Industry Adoption | Food trays, clamshells, medical packaging, blister packs | EV battery casings, aerospace interiors, biodegradable packaging |

| Market Growth Drivers | Food delivery, healthcare supplies, cost-effective solutions | Eco-packaging mandates, digitized lines, advanced materials |

New technology will help factories use less energy and make less waste. Companies will use more plastics that can break down or be recycled. There will be more need for custom and small-batch products. Electric cars and airplanes will also need more advanced thermoforming solutions.

The thermoforming industry will keep growing as new markets appear and technology gets better. Companies that try new ideas will be the leaders.

Plastic thermoforming machines are changing how things are made. Companies use automation and smart tools to work faster and better. Pressure forming helps make detailed shapes with great accuracy. Robots trim parts and use color-matched materials to save time. This also means factories do not need as many steps. New thermoplastics have recycled parts, resist flames, and look shiny.

Experts say to use biodegradable materials and designs that can be recycled.

Smart tools like IoT and AI watch machines and warn about repairs.

Heating that saves energy and hybrid machines help protect the planet.

Learning about new trends and tools helps companies stay ahead and do better work.

Factories often use plastics like ABS, PET, PVC, and polystyrene. These plastics get soft when heated and are easy to shape. They cool down fast and keep their new shape well. Each type is used for things like packaging, cars, or medical items.

Thermoforming uses most of each plastic sheet. Factories recycle the extra pieces left over. This way, there is less waste than with other methods. Many companies also use recycled or eco-friendly plastics to help the planet.

Thermoforming machines can make many different shapes. They do this by using special molds made for each product. Engineers design these molds with CAD software. Factories can change molds fast to make new things. This helps companies keep up with what customers want.

Thermoforming is safe for making food packaging. Factories use plastics that are safe for food and follow FDA rules. Machines keep the products clean and free from germs. Many food trays and containers are made this way.

Automation helps factories work faster and make fewer mistakes. Machines do the heating, shaping, and trimming jobs. Workers do not have to spend as much time on each part. This means better quality and more products in less time.