Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

PP cup thermoforming machines use heat and pressure to shape plastic sheets into cups. These machines are used in factories that make millions of cups every year. The global market for these machines is growing fast. Manufacturers want systems that work quicker and better.

The need for polypropylene is more than 30 million tonnes around the world.

Thermoformed plastics may be worth over USD 20 billion by 2030.

When picking a pp cup thermoforming machine, you should check some important details:

| Specification Category | Key Features |

|---|---|

| Machine Size and Production Capacity | Big forming area, fast cycle speed |

| Operational Ease and Automation | Easy controls, automatic functions |

| Material Compatibility | Heating zones can be changed for PP |

Choosing the right machine gives you steady results and saves money. Hengfeng’s new technology and helpful support let you get great performance.

PP cup thermoforming machines use heat and pressure to shape plastic sheets into cups. These machines make cups fast and keep the quality the same each time.

When you pick a machine, look at important things like forming area, how fast it works, and what materials it can use. This helps you choose the right one for your business.

Automation in thermoforming machines lowers labor costs and cuts down on mistakes. It helps factories make more cups in less time.

Hengfeng’s Multistation Thermoforming Machine has special features like fast mold changes and energy-saving parts. These features help you stay ahead of others.

Regular care and good support after buying are very important. They help your thermoforming machine work well and last longer.

A pp cup thermoforming machine shapes plastic sheets into cups using heat and pressure. You feed a flat sheet of plastic, like polypropylene (PP), into the machine. The machine heats the sheet until it becomes soft. Then, it presses the sheet into a mold to form the shape of a cup. After that, the machine cools the cup and cuts it out. This process lets you make many cups quickly and with the same size every time.

You will find pp cup thermoforming machines in factories that make cups for drinks, food, and other uses. These machines help you produce large numbers of cups with less waste. They also let you use different types of plastic, so you can choose the best material for your needs.

Tip: When you look for a pp cup thermoforming machine, check the specifications. These details tell you how fast the machine works, what materials it can use, and how much it can produce.

You start by loading plastic sheets into the machine. The machine heats the sheets to the right temperature. Next, it uses air pressure or a vacuum to push the soft plastic into a mold. The mold gives the cup its final shape. After forming, the machine cools the cup and trims the edges. Some machines also stack the finished cups for you.

Hengfeng stands out as a leader in this field. Many companies trust Hengfeng because:

The company leads in innovation for thermoforming cup machinery.

Hengfeng focuses on energy-saving and eco-friendly technology.

You get high-quality machines and strong global support.

With Hengfeng, you can expect reliable machines that help you meet your production goals.

Image Source: unsplash

When you pick a pp cup thermoforming machine, you should look at some key details. These details help you know how the machine works and what it can do for your business.

Forming Area

The forming area shows the size of cups you can make. Most commercial machines have a big forming area. This means you can make more cups each time.

| Max. Forming Area | Dimensions (mm) |

|---|---|

| 680 × 320 |

Production Speed

Speed is important if you want to make lots of cups fast. Machines from top brands can work very quickly. Some models make up to 174,000 cups in one hour. Others can work 30 times each minute, making 1,800 cups every hour.

OMV RM77: 174,000 cups per hour

TQC-750: 30 times per minute (1,800 cups per hour)

Material Compatibility

You need a machine that works with many plastics. Material compatibility affects how good your cups are. It also lets you change molds and tools fast, so you can keep up with market changes.

Material compatibility decides what plastics you can use, which changes product quality.

It helps you work faster by letting you use different molds and tools, making the machine more useful.

Being able to switch molds quickly helps you keep up when the market changes.

Automation Level

Automation makes your work easier. Machines with automatic stacking, cutting, and forming save time and help stop mistakes.

Air Pressure and Vacuum Forming

Good machines use air pressure and vacuum to shape cups. This gives you cups with sharp details and smooth sides.

Servo Motor Drive

Servo motors move the machine parts. This technology helps you get the same results every time. It also cuts down on waste and makes the machine work better.

Mold Change System

Fast mold changes mean you do not have to stop for long. You can switch from one cup design to another quickly. This keeps your work going without big breaks.

Tip: Always check the technical specifications before you buy a pp cup thermoforming machine. The right details help you reach your goals and save money.

Hengfeng’s Multistation Thermoforming Machine is special because of its advanced features. You get a machine that is fast, accurate, and flexible.

The machine works with many thermoplastic materials, like PP, PS, and PET. You can use it for different cups and packaging.

All movements use servo motor drive. This gives you good control and great results every time.

The forming process uses 6bar air pressure and vacuum. You get cups with sharp details and smooth sides.

The machine can go up to 50 analog beats per minute. You can make lots of cups quickly.

The mold rapid change device lets you switch molds fast. You spend less time setting up and more time making cups.

The automatic mold alignment system makes setup simple. Even if you are new, you can get good results. This system helps you make fewer mistakes and less waste. You get more good cups on the first try and your machine lasts longer.

New improvements in pp cup thermoforming machines include better servo motor technology. You can control the forming process more exactly. This means your cups look the same and you waste less material. Automation and robots help you work faster and make fewer mistakes. Better vacuum and pressure forming lets you make cups with cool shapes and smooth sides.

Rules for the environment make companies use better practices. Hengfeng’s machine lets you use eco-friendly materials and saves energy. You make less waste and use less power. Smart technology helps you make your work better and follow new rules.

Note: Hengfeng’s Multistation Thermoforming Machine gives you the flexibility to meet changing market needs. You get reliable performance, easy operation, and strong support from a global leader in thermoforming technology.

Image Source: unsplash

You want your factory to work well and make more cups fast. New pp cup thermoforming machines use automation to help with this. Automation means machines do most jobs, so you need fewer workers. This makes production faster and there are fewer mistakes.

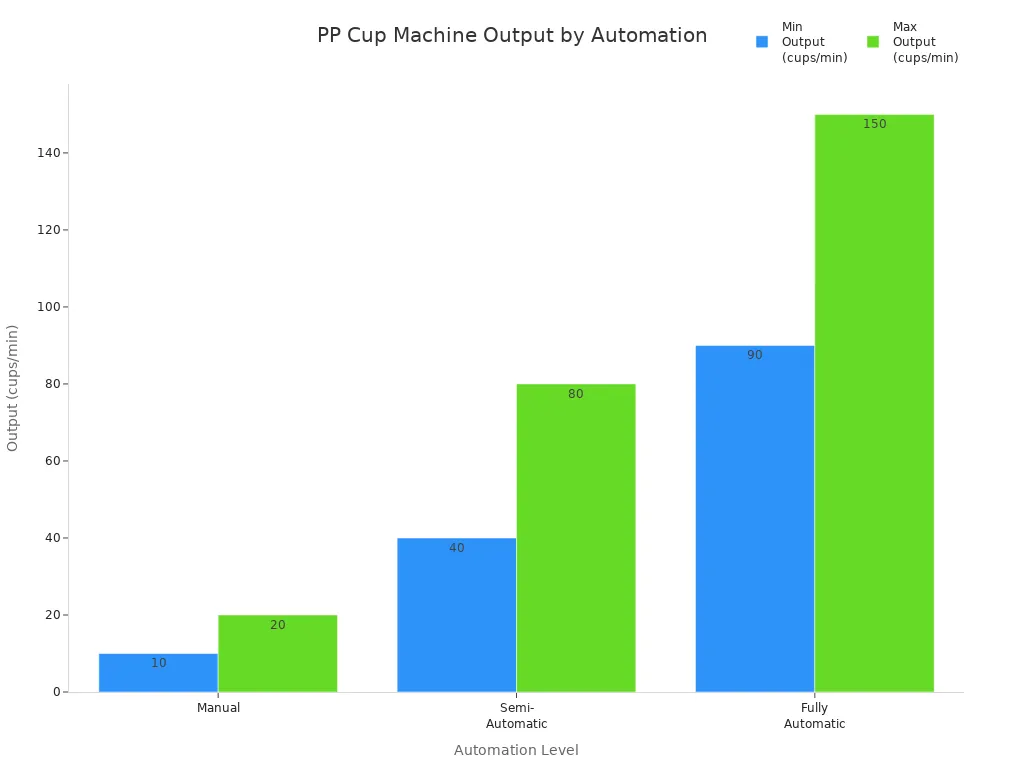

Here is a table that shows how different automation levels change labor needs:

| Machine Type | Automation Level | Labor Impact |

|---|---|---|

| Single-Station Automatic | High | Reduces manual intervention |

| Multi-Station Automatic | Very High | Further decreases labor costs |

| Vacuum Automatic | High | Minimizes need for manual handling |

| Combined Automatic | Full Automation | Significantly lowers labor needs |

| Specialized Automatic | High | Tailored for specific production needs |

You can see that multi-station and combined automatic machines need less labor. This helps you save money and lets you focus on other things.

Output is also important. Automated thermoforming machines make more cups each minute than manual or semi-automatic ones. Look at the table below:

| Automation Level | Output Range (cups/min) | Labor Required | Error Rate |

|---|---|---|---|

| Manual | 10–20 | 3–5 operators | 12% |

| Semi-Automatic | 40–80 | 1–2 operators | 6% |

| Fully Automatic | 90–150 | 0.5 operators | 1.8% |

You notice that fully automatic machines make lots of cups with fewer mistakes. You need fewer workers and get more cups in less time. Hengfeng’s Multistation Thermoforming Machine can make up to 48 units each minute. You can fill big orders and keep your customers happy.

Automation also helps you control how things are made. You set the machine and it keeps working at the same speed and quality. You do not have to worry about tired workers or mistakes. You get steady results every day.

Tip: Automation lets you make more cups without hiring more people. You can make more and keep costs low.

You want every cup to look the same and work well. Good quality is important in every step. New thermoforming machines use special checks to make sure each cup is right.

Here is a table that shows how machines keep quality high:

| Quality Control Measure | Description |

|---|---|

| Raw Material Inspection | Ensures plastic sheets are suitable for the process. |

| Temperature Control | Monitors heat to prevent cracking or bending of cups. |

| Mold Quality Inspection | Regular checks to avoid rough spots or incorrect sizes. |

| Forming Process Monitoring | Observes pressure, forming time, and cooling for consistency. |

| Cooling and Trimming Inspection | Verifies proper cooling and trimming for quality cups. |

| Tools and Technologies | Uses advanced tools like laser scanners and vision systems. |

You see that machines check every part of making cups. You get cups that are strong, smooth, and the right size. Hengfeng’s Multistation Thermoforming Machine keeps defect rates under 0.1%. You waste less material and get more good cups.

You save money by using less energy and making less waste. The three-station thermoforming machine does forming, cutting, and stacking all at once. You use less power than old machines. You can save up to 30% more energy with Hengfeng’s machine.

You also save money by using less plastic. You can make cups thinner but still strong. This means you use less plastic and make less waste. Good inventory management helps you use smaller rolls of plastic. You get less leftover scrap and match your material use to what you need.

Factories using Hengfeng’s Multistation Thermoforming Machine report:

Energy savings up to 30%

Defect rates under 0.1%

No accidents in over one million hours of use

You get lots of cups, great quality, and strong efficiency. You spend less on workers, energy, and materials. You keep your factory safe and working well.

Note: Picking a new pp cup thermoforming machine helps you reach your goals. You get better results, higher efficiency, and steady quality. Hengfeng’s machines help you grow your business and stay ahead in the market.

PP cup thermoforming machines are used in many industries. These machines help factories make products that meet different needs. The food and beverage industry uses these machines the most. Medical packaging and household products also use them a lot. Each industry wants cups with special features and good quality.

Here is a table that shows how each industry uses these machines and what they need:

| Industry | Application Requirements |

|---|---|

| Food and Beverage | Need for food-safe materials, high production efficiency, ability to produce various shapes |

| Medical | Compliance with health standards, production efficiency, customization options |

| Household Necessities | Durability, efficiency, and ability to produce diverse products |

Food and beverage companies use these machines to make safe and strong cups. They want cups that look nice too. Medical companies need machines that follow health rules. They also want to make special products. Makers of household goods want machines that can make many shapes and sizes.

Using these machines gives you many good things:

You use less material but cups stay strong.

You can add special finishes to make your brand stand out.

Automation helps you make more cups with fewer mistakes.

Markets change fast. You need machines that let you change your products quickly. PP cup thermoforming machines help you do this. You can change the size, shape, and design of your cups easily. This helps you keep up with what customers want.

Hengfeng works with many big brands around the world. You can trust Hengfeng to give you machines that fit your needs. The company helps with both big and small orders. You get machines that work for different types of products and quality levels.

With Hengfeng, you can:

Follow new packaging trends.

Meet tough safety and quality rules.

Make more cups without losing quality.

Use automation to save money and work faster.

Thermoforming is used for more and more products. You can make drink cups, medical trays, and other things. Hengfeng’s experience helps you find the best machine for your business.

You need a pp cup thermoforming machine that fits your needs. First, think about what cups you want to make. Next, decide how many cups you need each day. If you want to make lots of cups, pick a fast machine with automation. If you only need a few cups, a small machine is better.

Here is a checklist to help you:

Choose the type of cups you will make.

Pick the mold for forming, cutting, and stacking.

Figure out how many cups you need each hour.

Plan the mold layout and cooling time for best results.

Check how much molds and tools cost.

Test the machine to see how it works.

Work with a supplier who helps with product design and mold making. A supplier with cup experience can help you start faster and work better. Knowing your output is important. If you want to make many cups, get a machine that works fast and saves energy. If you need fewer cups, a simple machine is enough.

Tip: Automation helps you work faster and keeps things steady, even when you are busy.

Taking care of your machine keeps it working well. Hengfeng gives you good support after you buy the machine. You get help with setup, training for your team, and quick repairs. Spare parts come fast so you do not have to wait long.

| Service Type | What You Receive |

|---|---|

| Installation Help | Experts set up your machine |

| Training | Training for your workers |

| Maintenance | Quick repairs and help |

| Spare Parts | Fast delivery of parts |

Hengfeng gives you a warranty for parts and labor if something breaks. You can get more training and help whenever you need it. Regular checks help you stop problems before they start and keep your machine working well. With 24/7 support, you fix problems fast and keep making cups.

Note: Good support and regular care keep your machine safe and working for a long time.

You should know the technical specifications before you pick a PP cup thermoforming machine. These details help you find the best one for your needs. Hengfeng’s Multistation Thermoforming Machine lets you work fast and make good cups. The machine has features that help your business do well:

| Feature | Benefit |

|---|---|

| High forming area | Makes more cups each time |

| Advanced technology | Gives you steady quality |

| Easy maintenance | Stops long breaks |

| Certified quality | Keeps production reliable |

Hengfeng’s machines give you steady quality and quick results.

Follow the tips in this guide to choose the right machine for your factory.

Hengfeng’s skill and focus on quality help you do better than others.

You can make lots of packaging with this machine. It makes disposable cups, food containers, and trays. You can also make lids and special shapes for packaging. The packaging is strong and safe for many things.

Automation lets you control each step of making packaging. The machine keeps the same heat and pressure every time. This gives you smooth sides and sharp details on your packaging. You make fewer mistakes and waste less. Your packaging is always strong and looks nice.

You can use many materials with Hengfeng’s machine. It works with PP, PS, and PET. You pick the best material for what you need. This helps you keep up when the market changes. You can make packaging for food, drinks, and more.

You save money by using less energy and plastic. Automation helps you make more packaging with fewer workers. You can change molds fast to make new designs. You waste less material. Your packaging stays strong and safe while you spend less.

You get machines you can trust and good support. Hengfeng helps you make cups fast. You follow safety rules and keep quality high. You also get help with setup and repairs. Your packaging is always the same, and you finish big orders on time.