Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

Plastic bowl thermoforming machine technology has changed a lot. It started with people doing work by hand. Now, machines do most of the work by themselves. This change helps both companies and buyers. It makes bowls faster, better, and in more styles. Market numbers show it is growing fast:

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2024 | 46.2 | N/A |

| 2034 | 86.2 | 6.6 |

Now, companies use 3D modeling, simulation, and automation. These tools help them work better and beat other companies.

Plastic bowl thermoforming machines started with people doing the work by hand. Now, these machines are fully automatic. This change made them faster and better at making bowls.

Today’s machines use new technology like AI and automation. These tools help the machines be more exact. They also use up to 25% less energy.

Companies now care more about the environment. They use materials that can break down or be recycled. This is because customers want greener products.

Automation and smart controls help workers watch the machines in real time. This means there are fewer errors. It also makes the machines work better and faster.

Thermoforming is used in many businesses. It is very common in food packaging. This is because it makes products that are light and safe.

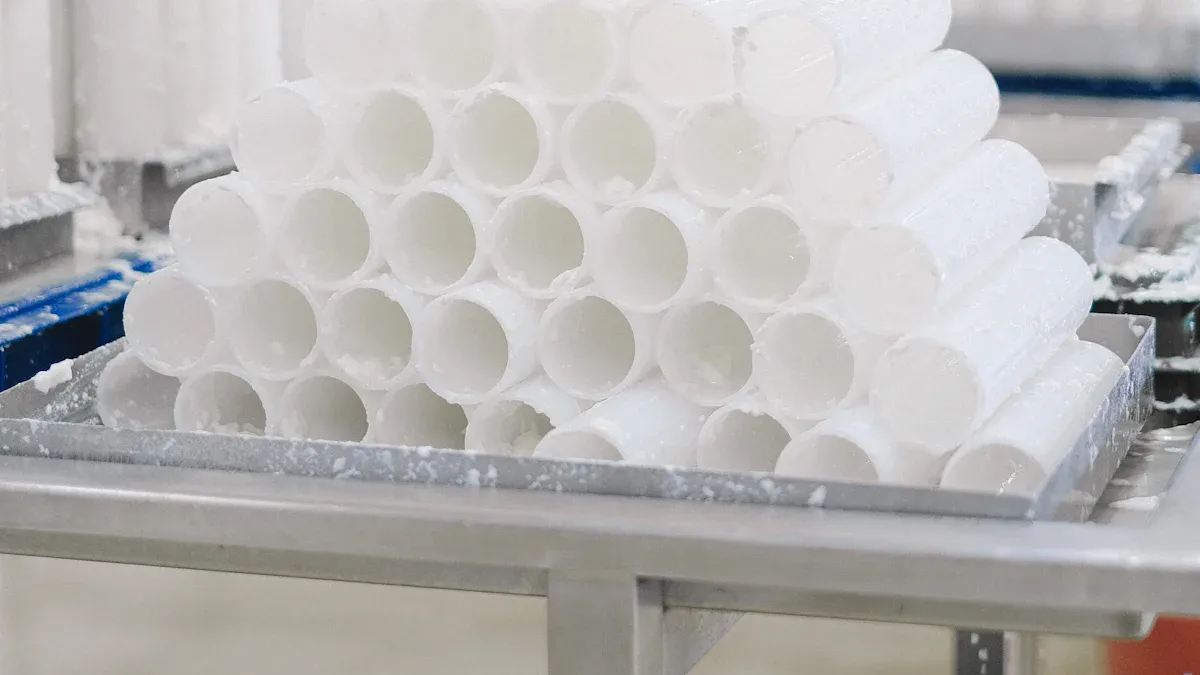

Image Source: pexels

The story of thermoforming started with Parkesine in 1855. Parkesine was the first plastic made from cellulose. This new plastic led to more inventions. John Wesley Hyatt made Parkesine better by adding camphor. He created celluloid, which was important for thermoforming. Hyatt used steam heat and pressure to shape celluloid. This showed that plastic could be used in many ways.

Early thermoforming machines were very simple. Workers heated plastic sheets with basic tools. They stretched the sheets over molds by hand. The process needed a lot of work and skill. Results were not always the same. Making many items was hard. The process was slow and not exact.

Early thermoforming used:

Heating plastic sheets by hand

Stretching sheets over molds by hand

Steps that needed a lot of work

Things changed when Strauch made the roll-fed machine. This machine let plastic sheets move without stopping. It made thermoforming faster and easier. Workers did not need to reload materials often. The roll-fed machine cut down on manual work. It also made products better.

| Advantage | Description |

|---|---|

| Enhanced Productivity | The machine worked all the time and made more items. |

| Reduced Manual Intervention | Less work for people meant fewer mistakes and lower costs. |

| Consistent Product Quality | Products looked the same and met higher standards. |

| Optimal Material Utilisation | Plastic was used better, so there was less waste. |

| Cost-Efficiency | Saving money on work and materials helped companies earn more. |

As technology got better, special machines for plastic bowls appeared. These machines made bowls quickly and with great accuracy. The plastics industry grew and wanted greener choices. Companies started using biodegradable and recyclable materials. This helped meet new needs.

| Evidence | Description |

|---|---|

| Sustainable Materials | Companies use plastics that break down or can be recycled for bowls. |

| Consumer Interest | People want packaging that is better for the planet. |

| Environmental Awareness | More people care about green products, so companies make better bowls. |

Thermoforming keeps changing. Now, it makes many useful things, like bowls, faster and with less waste.

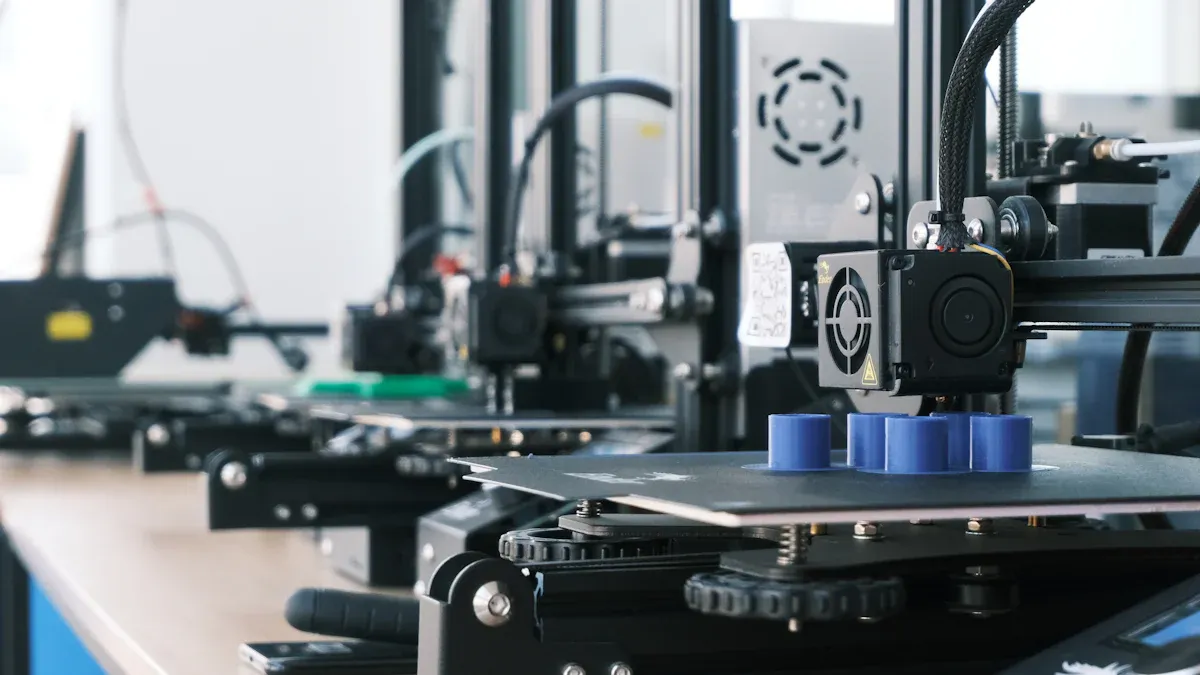

Image Source: unsplash

Today’s thermoforming systems use automation to make work better. These systems have many parts that help shape plastic bowls very accurately. Operators use control systems to run heating, forming, cooling, and trimming. Automation lets workers watch the process and make fast changes. This helps keep the quality the same every time.

| Component | Role in Production Outcomes |

|---|---|

| Heating System | Makes sure materials get hot enough to form. |

| Forming Station | Shapes the hot material into the right bowl shape. |

| Cooling System | Cools the bowl quickly so it stays strong. |

| Trimming Station | Cuts off extra plastic for a neat look. |

| Control System | Runs the whole process to keep things exact. |

| Material Handling System | Moves materials through each step of the process. |

| Automation and Robotics | Speeds up work and means people do less. |

| Energy Management System | Saves energy and helps lower costs. |

| Safety Features | Keeps workers safe while machines are running. |

New ideas help make machines more exact, fast, and earth-friendly. Better control systems let workers set heat and timing just right. Watching the machines in real time helps check how well they work. More companies now use automated vacuum thermoforming machines. These machines are getting more popular. Makers now build machines that use recycled and biodegradable plastics. This shows they care more about the planet.

Better control systems help make bowls the same every time.

Workers can set heat and timing very carefully.

Watching machines live helps check how they are working.

Makers now use machines that work with recycled and biodegradable plastics.

Bigger machines can make more bowls faster.

Modern machines can make bowls much faster than before. Automation and robots help speed up work by 20%. Machines now use 25% less energy. They also stop working less often, which saves time. Smart computer systems help use less energy and make more bowls. Inline thermoforming lets machines work without stopping, so they make more bowls.

Machines now work 20% faster than before.

They use 25% less energy than old machines.

Machines break down 20% less often because of new tech.

Smart computer systems save up to 20% more energy and make 15% more bowls.

IoT helps machines work better and need less fixing, cutting downtime by 20%.

New controls and automation mean less work for people and fewer mistakes.

Modern machines use servo motors to save 30-40% energy. They waste less plastic, with only 3% or less thrown away. Modular designs help change tools faster. Sealed oil systems mean less fixing is needed. Inline systems make the whole process quicker and more steady.

| Aspect | Modern Machines | Earlier Models |

|---|---|---|

| Energy Consumption | Servo motors save 30-40% energy | Used more energy |

| Material Utilization Rate | Only 3% or less wasted | Wasted more plastic |

| Tooling Changeover Time | Modular designs make changes fast | Took longer to change |

| Maintenance Requirements | Sealed oil means less fixing | Needed more repairs |

Modern machines can now make bigger parts and work faster. This helps companies make lots of bowls at once. These machines can change quickly to make different things. Modular designs help workers switch tools fast, making work more flexible.

| Innovation Type | Description |

|---|---|

| Automation | Machines do heating, forming, and trimming to avoid mistakes and work faster. |

| Digital Integration | Using CAD/CAM makes work smoother and saves time and money. |

| Material Science Advances | New materials are safer, last longer, and are easier to use, making bowls better and faster. |

| IoT Connectivity | Watching machines live helps fix problems before they stop working. |

| 3D Printing Integration | Mixing 3D printing with thermoforming helps make new products and custom bowls faster. |

Big machines can be hard to design and may not make bowls with even walls. Deep molds can make some parts weak. Cutting off extra plastic can waste material and lower efficiency. Still, using recycled and compostable plastics has grown by 46%. Makers keep working to make machines bigger and more flexible. Now, inline and high-speed machines can make many kinds of plastic products.

Tip: Companies that buy bigger, faster, and inline thermoforming machines can keep up with what customers want and work better.

Thermoforming is now much more accurate than before. Companies use better vacuum systems and pressure forming. These help shape plastic bowls with tiny details. Digital tools like AI and machine learning help control the process. They also find mistakes early. These changes make bowls lighter, stronger, and more dependable.

| Advancement Type | Description | Impact on Product Quality |

|---|---|---|

| Improved Vacuum Systems | Make it easier to mold small details. | Bowls are lighter and work well. |

| Innovations in Pressure Forming | Give bowls smooth surfaces and cool textures. | Bowls look and work better. |

| Integration of Digital Tools | Use AI and machine learning to check quality. | Bowls are made faster and with fewer mistakes. |

Manufacturers use strict rules to keep every bowl the same. Tighter rules mean bowls are made more exactly. For example, most bowls stay within ± .020 inches in size. Holes and slots have their own limits, based on how big they are. Different plastics need different rules because they act differently when shaped.

Tolerances are important for how exact bowls are made.

Tighter tolerances mean bowls are more exact.

Different plastics need different tolerances because they act differently.

Thermoforming is now used in many industries. Food packaging is the biggest use. Asia-Pacific makes almost half of these products. Medical devices, things people buy, and car parts also use these bowls.

| Industry Sector | Projected Market Growth | CAGR (%) | Dominant Region |

|---|---|---|---|

| Food Packaging | $1.8 billion by 2028 | 5.2 | Asia-Pacific (45%) |

| Medical Devices | North America | ||

| Consumer Packaged Goods | Europe | ||

| Automotive |

New technology helps companies make less waste and use less energy. Digital modeling and robots help make more products. The food and drink industry uses more thermoformed packaging. This keeps food fresh and safe.

Companies must follow strict rules to sell plastic bowls. They follow FDA or EFSA rules for food safety. Many use food-safe materials like PET and get special certificates like ISO 22000. These steps help keep bowls safe and clean.

Use food-safe materials like PET in making bowls.

Get certificates like ISO 22000 for food safety.

Note: Companies also use FDA-approved resins, follow Good Manufacturing Practices, and test for harmful chemicals. They must track all materials for safety and quality.

Thermoforming keeps getting better. Now, plastic bowls meet high standards for quality, safety, and how well they work.

Industries want packaging that is better for the earth. Thermoforming makes packaging light and easy to recycle. This helps companies use greener ways to make things. Food, healthcare, and consumer goods companies use this process to help nature. New trimming and nesting methods help use less material. The HEY02 Four Stations Machine works better and can cut waste by 30%.

Thermoformed packaging uses polyethylene and polypropylene. These are easy to recycle and hurt the earth less.

Biodegradable materials like polylactic acid break down on their own and help the planet.

Companies use fewer new materials and can recycle what they use. This means less pollution and fewer resources used.

Thermoforming now lets companies make more shapes and designs. Special thermoforming equipment helps make products with curves and angles. New materials give more ways to customize. CAD and automation help make detailed parts with high accuracy.

| Aspect | Description |

|---|---|

| Design Flexibility | Thermoforming makes shapes and angles other methods cannot. |

| Material Options | New materials give more choices for custom designs. |

| Integration with Technology | CAD and automation make complex parts more accurate and faster. |

Companies use more earth-friendly materials to make products.

Robots and digital tools help make parts with exact details.

CAD and simulation software help improve designs and need fewer test models.

Thermoforming makes complex ductwork and adapters for less money.

Pressure forming uses vacuum and air to make detailed and textured parts.

Aerospace companies use thermoforming to make strong, light bins and panels.

Smart manufacturing will change new machines. Automation is important because there are fewer workers and companies need to work faster. Smart controls like PLC and HMI touchscreen systems let workers watch machines live. Automatic recycling of materials helps save resources.

| Feature | Description |

|---|---|

| AI Integration | New machines use artificial intelligence to work better and adapt. |

| Predictive Maintenance | AI watches machines and finds problems early, so they break less. |

Automation makes work faster and helps reach goals.

Smart controls and live monitoring make work safer and more steady.

Automatic recycling cuts waste and helps green goals.

High-speed mass production will help companies make more packaging parts.

Tip: Companies that buy smart and inline machines will do better in quality, speed, and helping the earth.

The history of the plastic bowl thermoforming machine has different steps.

| Stage | Description |

|---|---|

| Early Days of Thermoforming | People did all the work by hand and used simple heaters. |

| Transition to Semi-Automated Systems | Machines started to help people, making work easier and more even. |

| Fully Automated Thermoforming | New technology made machines that could do everything by themselves. |

Now, the plastic bowl thermoforming machine works faster and makes better bowls. Companies use robots, better heating, and earth-friendly ways. The plastic bowl thermoforming machine helps set new trends and supports recycling. Experts think smart plastic bowl thermoforming machine systems will use AI and quick-change tools. The plastic bowl thermoforming machine will keep getting better for both companies and buyers.

Thermoforming means heating plastic sheets until they get soft. Then, workers or machines press the plastic onto a mold. This makes bowls that are strong and light. These bowls are used for food and in other businesses.

Modern machines have special controls and sensors. These keep the heat and shape just right. Because of this, bowls have fewer problems. They also meet tough industry rules.

Thermoforming is fast and does not waste much material. Companies can make lots of bowls quickly. The process lets them make bowls in many shapes and sizes. This helps with different packaging needs.

Yes. Many companies now use recycled or biodegradable plastics. This helps cut down on waste. It also supports green goals in packaging.

Plastic bowls must follow food safety rules from groups like the FDA or EFSA. Companies use safe materials and test bowls. This makes sure bowls are safe for people to use.