Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

When you want the best results, first look at what you need to make. Think about the machine types and the help you get from the plastic cup thermoforming machine manufacturer. Picking the right machine for your plastic cup type helps you work faster and safer. You should also think about mold cost, automation, and help after you buy the machine. You want a machine that meets your safety rules and keeps your plastic cup line working well. Look at the table below to see how the right features can help you work better and safer.

| Feature | Impact on Production Efficiency and Safety |

|---|---|

| Cup Sizes and Shapes | Makes the exact plastic cup you want, wastes less, and stops safety problems. |

| Material Compatibility | Uses safe plastics, works faster, and keeps each plastic cup good quality. |

| Level of Automation | Needs less hand work, makes fewer mistakes, and keeps your team safer. |

| Energy Efficiency | Saves energy money and makes your work area safer with better machines. |

A checklist can help you stay on track and keep safety first.

Figure out how many cups you need to make each day. This helps you pick a machine that fits your needs.

Think about the types and sizes of cups you want to make. Small cups use less material. Big cups might waste more material.

Check if the materials and molds work with the machine. Make sure your plastic works well with the machine. This keeps your cups good and saves time.

Look up the manufacturer’s reputation and experience. A trusted company gives better help and good machines.

See if the manufacturer offers training and maintenance help. Good support helps you use the machine safely and easily.

Image Source: unsplash

You want to start by figuring out how many cups you need to make each day. This number helps you pick a cup thermoforming machine that matches your production capacity. If you plan for high volume cup production, you need a machine that can keep up without breaking down. Think about your busiest times. Will you need to make more cups for special events or holidays? Write down your target production capacity so you can share it with manufacturers. This step makes sure you get a machine that fits your cup production goals.

Next, look at the cup size and shape you want to offer. Do you need small cups for tastings, medium ones for drinks, or large cups for parties? Each size affects your production capacity and the type of mold you need. Here’s how different cup sizes and types can influence your choice:

Smaller cups use less plastic and energy, so you waste less.

Bioplastic cups break down faster than regular plastic, which is better for the planet.

Picking the smallest cup that works for you helps lower your impact on the environment.

Small cups work well for samples but need more refills.

Medium cups fit most drinks and cut down on refills, great for events.

Large cups are easy for guests but can lead to more waste.

Now, think about what plastic you want to use. Material compatibility matters because not every mold works with every plastic. Some common plastics include:

Polystyrene (PS): Lightweight and strong, good for disposable cups.

Polyethylene Terephthalate (PET): Clear and tough, often used for bottles.

Polypropylene (PP): Flexible and durable, great for many uses.

Acrylonitrile Butadiene Styrene (ABS): Tough and heat-resistant.

The right material affects how well your mold works and how smooth your cup production runs. Some plastics, like ABS and HIPS, are easy to shape and help you make cups faster. Always check that your chosen material and mold have good compatibility before you buy.

When you look at cup thermoforming machine choices, you’ll see both manual and automatic models. Each type fits different production needs. Here’s a quick look at how they compare:

| Type of Machine | Output Speed | Labor Requirements |

|---|---|---|

| Automatic | High-speed | Minimal human intervention |

| Manual | Lower speed | Significant labor input |

If you want to make lots of cups fast, automatic machines work best. They need less help from workers and keep your line moving. Manual machines cost less at first, but you need more people to run them. For small batches or testing new cup designs, manual machines can make sense.

You should check the features before you buy. Some features matter more than others. Take a look at this table to see what most cup makers value:

| Key Features | Description |

|---|---|

| Production Requirements | Match the machine to your cup and plastic type. |

| Machine Features | Look at heating, shaping, cutting, and automation. |

| Cost Considerations | Think about price and long-term savings. |

| Manufacturer Reputation | Pick a company with good support. |

| Quick-Change Capabilities | Switch molds fast to save time. |

| Mold Change Design | Tool-less changes help you work quicker. |

| Control Systems | Easy controls save your settings. |

| Productivity Features | Boost speed and cut down on waste. |

| Sustainability Focus | Use recycled or green plastics for better energy efficiency. |

The forming area tells you how many cups you can make at once. A bigger forming area means more cups per cycle, but you need to make sure it fits your space and needs.

The mold selection process can change your costs and how flexible your production is. Here’s what you need to know:

Low volume production molds cost less and let you change designs quickly. These work well if you want to test new cups or fill small orders.

High performance injection molds cost more at first but save money over time. They make lots of cups with high quality and work best for big orders.

If you plan to grow your business, think about how easy it is to swap out molds and how much each type will cost you in the long run.

Image Source: pexels

Picking the right plastic cup thermoforming machine manufacturer is very important. The right partner will help your business grow and support you. Here are some ways to find a manufacturer you can trust.

Always look at the reputation of any plastic cup thermoforming machine manufacturer. A good reputation means the company keeps its promises and supports its products. Experts say you should check these things:

Each cup should look the same, with no mistakes or sharp edges.

The machine should make many cups fast and keep them good quality.

You need a team that helps you quickly when you have problems.

The best companies add new features and make their machines safer.

You can also see how long the manufacturer has been making machines. More years in business often means better machines and more experience. Look at this table to compare top companies:

| Manufacturer | Years of Experience |

|---|---|

| Mesoforming | 12 |

| Global Thermoforming | 30 |

A company with many years of experience usually makes reliable machines. They also know how to make molds that last and keep your line running well.

Tip: Ask the manufacturer about safety features. Good machines keep workers safe and help stop accidents.

Certifications show that a plastic cup thermoforming machine manufacturer meets important rules. You want proof that their machines are safe and good for food packaging. Here are some certifications to look for:

| Certification | Description |

|---|---|

| FDA Certification | Shows the machine is safe for food in the U.S. |

| CE Marking | Means the machine meets health and safety rules in Europe. |

| ISO Certifications | ISO 9001 is for quality, ISO 14001 is for the environment. |

| HACCP Certification | Helps keep food safe by finding and fixing dangers. |

When you see these certifications, you know the manufacturer cares about safety and quality. Their machines are also more likely to work well with different molds.

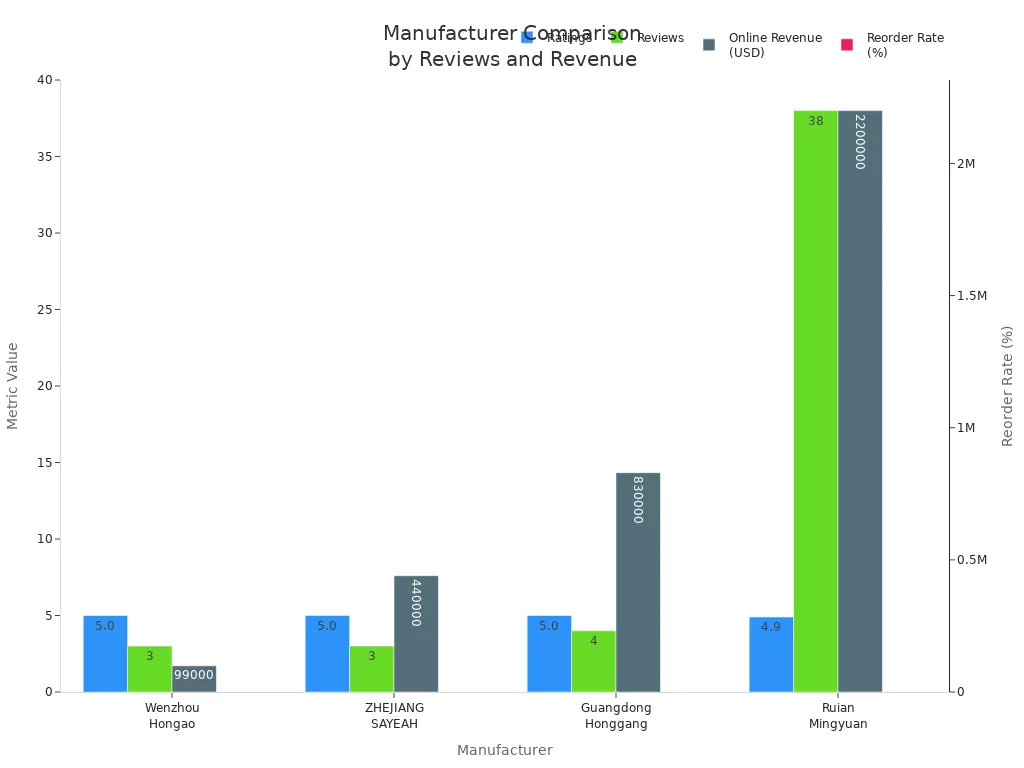

Customer feedback shows how a manufacturer treats its buyers. High ratings, repeat orders, and good reviews mean you can trust the company. Here is a table to compare some top manufacturers:

| Manufacturer Name | Ratings | Reviews | Online Revenue | Reorder Rate |

|---|---|---|---|---|

| Wenzhou Hongao Trade Co., Ltd. | 5.0 / 5.0 | 3 reviews | US $99,000+ | 15% |

| ZHEJIANG SAYEAH MACHINERY CO.,LTD | 5.0 / 5.0 | 3 reviews | US $440,000+ | <15% |

| Guangdong Honggang Intelligent Equipment Co., Ltd. | 5.0 / 5.0 | 4 reviews | US $830,000+ | 33% |

| Ruian Mingyuan Machine Co., Ltd. | 4.9 / 5.0 | 38 reviews | US $2,200,000+ | 29% |

Some companies have high reorder rates and strong sales. This means customers like their machines and buy again. Read the reviews to see what people say about mold changes, support, and safety features.

Think about the environment too. Many companies now use plastics that are better for the planet and make machines that use less energy. Here are some things to remember:

Thermoformed plastic can be better for the environment if you recycle it.

The industry now cares more about the environment, not just saving money.

Using better plastics helps lower waste and your carbon footprint.

When you pick a plastic cup thermoforming machine manufacturer with a good reputation, the right certifications, and happy customers, your business will do better. You also make sure your machines work well with your molds and keep your team safe.

You want your machine to work well from the start. Good manufacturers give you training and help with installation. This support teaches you and your team how to use the machine safely. You also learn how to fix small problems quickly. Here are some types of help you might get:

| Type of Support | Description |

|---|---|

| On-site Training | You learn by using real machines at your factory. |

| Remote Training | You can watch lessons online when you have time. |

| Installation Guidance | You get step-by-step help to set up your machine. |

| Professional Training | Experts teach you for free before or after you buy. |

| Online Support | You get help with setup and fixing problems after delivery. |

| Operation Manual | You get easy guides and videos for daily use. |

| Thermoforming Training | You learn about the forming process and how to reuse scrap plastic. |

Tip: Ask if you can get training on reusing leftover plastic and changing molds quickly.

To keep your machine working, you need a good maintenance plan. You also need spare parts close by. If you have spare parts ready, you can fix problems fast. This helps you avoid long stops and keeps cup production going. Here is a simple schedule for maintenance:

| Frequency | Maintenance Tasks |

|---|---|

| Daily | Check important parts, clean, add oil, and watch how the system works. |

| Weekly | Adjust controls, look at mold condition, and test safety features. |

| Monthly | Check electrical and cooling systems and change worn parts. |

| Quarterly | Follow maker’s rules, write down work, train staff, and use good parts. |

| Annual | Do a full check and fix big systems. |

Spare parts nearby help you fix problems fast and stop delays.

Downtime can hurt your business and make customers unhappy.

Good maintenance and support keep your production line moving.

When you look at price, think about more than just the first payment. The total cost includes plastic sheets, molds, worker pay, and how fast the machine works. Here is what you should check:

| Factor | Description |

|---|---|

| Raw Material Costs | The money you spend on plastic sheets. |

| Mold and Tooling Costs | The price for each mold, which can be a big part of your budget. |

| Labor and Operation Costs | Pay for workers and time spent on each batch. |

| Cycle Time and Efficiency | Faster machines save you money over time. |

If something breaks, they help with repairs and send free parts. You only pay for shipping.

Good warranty and fast support add value and lower your risk.

Note: Reliable after-sales support keeps your line running and helps you fix problems quickly.

You need to find the best plastic cup thermoforming machine manufacturer. First, think about how many cups you want to make. Pick a machine that matches your output, plastic type, and space. Experts say you should do these things: 1. Pick a machine that can handle your daily cup amount. 2. Make sure the machine works with your plastic. 3. Choose if you want a manual or automatic machine. 4. Look for machines that use less energy. 5. Check if the machine fits in your factory. A checklist helps you look at choices, prices, and support. Ask lots of questions and see the machine working before you buy. Good choices help your business grow and keep up with new ideas.

Manual machines need you to do more work. Automatic machines run with less help. Automatic models make more cups faster. Manual ones cost less but need more workers.

Check the forming area in the machine specs. Match your cup’s height and diameter to the forming area. If you are not sure, ask the manufacturer for a sample run.

Most machines work with PS, PET, PP, and ABS. Some models handle bioplastics. Here’s a quick look:

| Plastic Type | Common Use |

|---|---|

| PS | Disposable cups |

| PET | Clear cups |

| PP | Durable cups |

| ABS | Heat-resistant |

Yes! Good manufacturers give you training, spare parts, and fast support. Always ask about after-sales service before you buy. This keeps your line running and saves you stress.