Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

Disposable Cup Thermoforming Machines help companies make cups fast. These machines use new technology to save energy. They can cut energy use by 30%. This helps save money and helps the environment. Most machines can make thousands of cups every hour. Some machines make up to 170,000 cups each hour. Manufacturers use many materials like polystyrene, polypropylene, and polyethylene. Hengfeng makes machines that save energy and work automatically. Machine features are important for how many cups get made. They also matter for what materials a business can use.

Pick machines that have good automation and save energy. This helps make more cups and lowers costs.

Machines that work faster make more cups in less time. Shorter cycles mean you can produce more cups.

Choose machines that use different materials. This helps you serve more customers and follow new trends.

Think about both efficiency and flexibility when picking a machine. This helps you avoid problems later.

Use Hengfeng's custom options for solutions that fit your business needs.

Automation helps make cups faster and with fewer mistakes. Modern Disposable Cup Thermoforming Machines use smart technology to work better:

Robots and cobots do jobs like loading, unloading, trimming, and polishing. These machines work fast and help stop errors.

Control systems use sensors and PLCs to check every step. This keeps the cups looking good and all the same.

Cameras and sensors find problems early. This stops waste and keeps products the same.

Energy-saving features help companies spend less money. Machines with special heating zones and auto shut-off use less power. Some machines can save up to 30% energy. Smart technology lets workers watch and change settings right away. This cuts waste and helps make more cups. Good heating systems warm materials fast and evenly. This saves money and keeps the line moving.

Tip: Pick machines with strong automation and energy-saving parts. This helps factories make more cups with less work and lower costs.

Cycle time is how long it takes to make a batch of cups. Shorter cycle times mean more cups get made. For example:

If a machine goes from 30 seconds to 20 seconds per cycle, it can make 50% more cups in the same time.

Faster cycles use less energy for each cup, so companies save money.

Companies that make cups quickly can sell for better prices and stay ahead.

Factories want machines that are fast and make good cups. Quick cycles and smart controls help fill big orders without losing quality.

Hengfeng’s Multistation Thermoforming Machine is known for being smart and efficient. It uses servo motors for exact moves and has a fast mold change tool. This makes fixing the machine easy and saves time. The machine works with 6-bar air pressure and vacuum. This helps make high-quality cups.

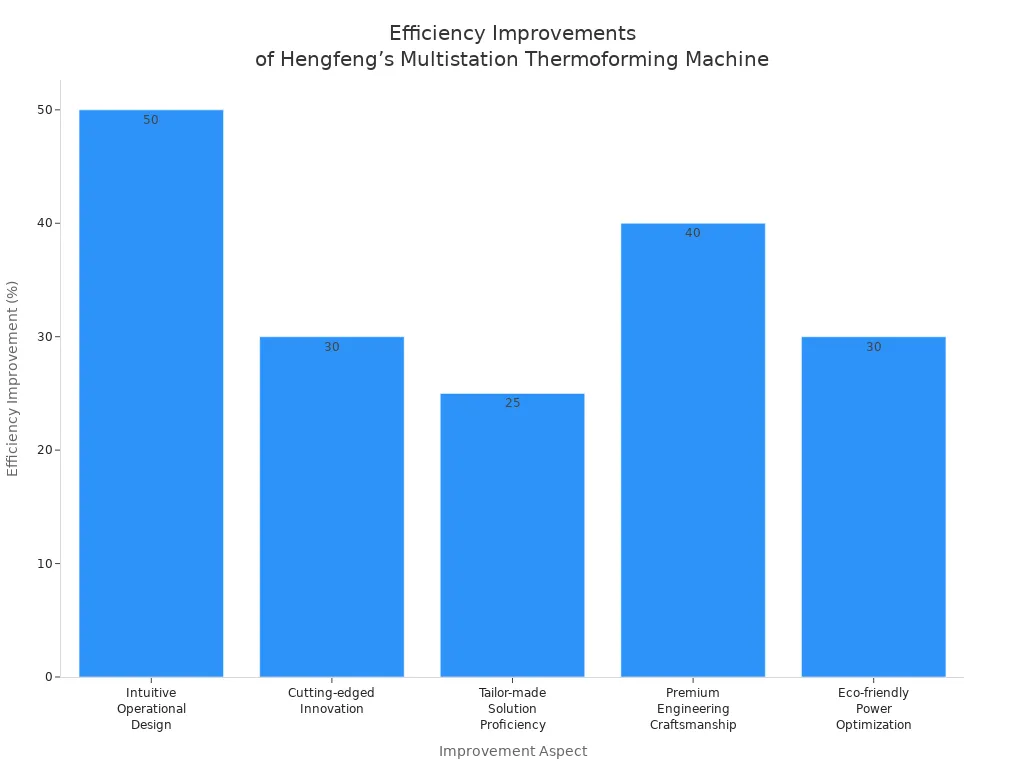

The table below shows how Hengfeng’s Multistation Thermoforming Machine gets better in many ways:

| Improvement Aspect | Documented Efficiency Improvement |

|---|---|

| Intuitive Operational Design | 50% less training time, 35% fewer mistakes, 20% better OEE |

| Cutting-edged Innovation | 30% better production, parts are more exact by 0.05mm |

| Tailor-made Solution Proficiency | 25% more output, up to 40% faster cycle times |

| Premium Engineering Craftsmanship | 99.7% uptime, MTBF of 5,000 hours, 40% less capital cost |

| Eco-friendly Power Optimization | 30% less energy used, $15,000 saved each year, 25% less carbon footprint |

Hengfeng’s machine does well compared to other brands. It uses 30% less power and can make up to 48 units each minute. The machine keeps defects under 0.1% and has quick-change molds for different jobs. Hengfeng’s Multistation Thermoforming Machine won the Best in Class award in 2023 for safety and performance.

Disposable Cup Thermoforming Machines with smart automation, fast cycles, and energy-saving features help companies make lots of cups. Hengfeng’s focus on new ideas and efficiency gives factories a big advantage in making cups.

Image Source: pexels

Disposable Cup Thermoforming Machines can make lots of cups fast. In big factories, some machines run up to 30 cycles each minute. This means they form, cut, and stack cups very quickly. Hengfeng has machines that make thousands of cups every hour. Fast machines help factories fill big orders and keep up with busy times.

Machines can run up to 30 cycles a minute.

Some models make tens of thousands of cups each hour.

Fast output helps companies finish big orders quickly.

Many things change how many cups a machine makes. The most important things are:

Material Quality

Operator Skill and Training

Maintenance Practices

Production Layout and Workflow

Demand and Order Size

Environmental Considerations

Each thing matters. Better machines work faster. Good materials help the machine run well. Skilled workers and regular care keep machines working. A smart factory layout helps make more cups.

Factories need to pick machines that fit their size and goals. Automation helps make more cups. The table below shows how automation helps:

| Benefit | Description |

|---|---|

| Increased Throughput | Automated systems work all the time, so they make more cups. |

| Consistency | Automation keeps every cup the same, so quality is better. |

| Labor Savings | Fewer workers are needed, so costs go down and mistakes are fewer. |

Small businesses may want machines that make fewer cups. Big companies with lots of orders need fast machines. Hengfeng has different machines for different needs. Companies should think about order size, space, and future plans before picking a machine.

Image Source: pexels

Factories use different plastics to make disposable cups. The main ones are polypropylene (PP), polystyrene (PS), polyethylene terephthalate (PET), and polylactic acid (PLA). Polypropylene is the most used plastic for cups. In 2023, PP made up more than 21% of all thermoformed plastics. PP is good for hot drinks because it can handle heat well. Polystyrene and PET are also important. PET is clear and strong, so it is great for cold drinks. PLA is compostable, but it cannot take much heat and needs special ways to throw it away.

The table below shows how these plastics work for making cups:

| Feature/Property | PP (Polypropylene) | PS (Polystyrene) | PET (Polyethylene Terephthalate) | PLA (Polylactic Acid) |

|---|---|---|---|---|

| Heat Resistance | High (~120°C) | Low | Low (~70°C) | Very Low (~45°C) |

| Clarity | Good | High | Excellent | Excellent |

| Durability | High | Low | High | Low |

| Moisture Barrier | Excellent | Moderate | Good | Moderate |

| Primary Use | Hot Beverages | Cold Drinks | Cold Drinks | Premium Cold Drinks |

PP cups are best for hot drinks. PET cups are strong and clear, so they are good for cold drinks. PLA cups can break down in compost, but they do not work with hot drinks.

How a Disposable Cup Thermoforming Machine is built changes what plastics it can use. Machines with smart controls and good temperature settings can use more types of plastics. These features help make better cups and waste less material. If a machine can switch plastics fast, factories can make many kinds of cups.

Some important machine features for using different plastics are:

| Design Feature | Benefit |

|---|---|

| Ability to handle various raw materials | Processes multiple material types efficiently |

| Advanced automation | Ensures consistent quality and reduces waste |

| Precise temperature control | Improves the quality and strength of the cups |

When machines can use many plastics, it helps in many ways.

The right plastic makes the cup work better for its job.

Using strong and cheap plastics saves money.

Machines that work with many plastics make it easier to run the factory.

Note: Machines that can use many plastics help factories keep up with new trends and customer needs.

Hengfeng’s Multistation Thermoforming Machine can use many kinds of thermoplastic materials. It works with PP, PS, PET, and PLA, which meets and even beats normal standards. Hengfeng’s machine uses smart controls and is easy to run fast. Workers can learn to use it quickly and make fewer mistakes. The machine can change molds fast and keeps cup quality the same with each plastic.

The table below shows how Hengfeng’s machine compares to others:

| Feature | Hengfeng's Multistation Thermoforming Machine | Industry Standards |

|---|---|---|

| Range of Materials Supported | Wide range, including eco-friendly options | Less specified breadth |

Hengfeng spends money on research to make its machines better. Every year, the company adds new features to improve speed and flexibility. Hengfeng’s Multistation Thermoforming Machine lets factories make cups for hot drinks, cold drinks, fancy cups, and green products.

Hengfeng’s machine works with many thermoplastic materials.

It runs fast and is simple to use.

The machine’s accuracy and speed help factories do well.

Smart controls save energy and let factories make more types of cups.

New updates make the machine work better every year.

Disposable Cup Thermoforming Machines that use many plastics help factories make good cups for lots of uses. Hengfeng’s Multistation Thermoforming Machine is special because it can use many plastics and has a smart design.

Picking the right Disposable Cup Thermoforming Machine helps factories do well. Companies need to think about efficiency, output, and what materials the machine can use. These things change how the machine works and how much it costs.

The table below gives tips for choosing a machine:

| Best Practice | Description |

|---|---|

| Material Selection | Choose the best thermoplastic for clear cups, strong cups, and recycling. |

| Automation | Use automation to save work, stop mistakes, and make cups faster. |

| Production Requirements | Make sure the machine makes enough cups and works with your favorite materials. |

| Machine Features | Look at heating, forming, trimming, and automation choices. |

Factories need to keep things efficient and strong. Making things more efficient saves money, but it can make the system less able to change. If orders go up or down fast, a system that is not flexible can cost more later. Inventory controllers help, but too much efficiency can hurt flexibility. Companies should find a good balance so things run smoothly.

Tip: Think about what you need now and later before picking a machine. This helps you avoid problems and keeps costs down.

Hengfeng lets customers change machines to fit their needs. The company makes special equipment and can change quickly when the market does. Hengfeng’s team listens to customers and changes machines for special plastics or cup shapes.

| Customization Option | Description |

|---|---|

| Tailored Equipment | Machines made for what each business needs. |

| Market Responsiveness | Quick changes for new customer requests. |

Hengfeng helps customers all over the world. The company sets up machines, teaches workers, and fixes problems. Hengfeng’s experts answer questions and help fast. Customers can pick machines like the Automatic PP HIPS Pet Cup Thermoforming Machine with custom parts. Hengfeng’s team works with each company to make sure the machine is right.

Hengfeng makes custom machines for special cup styles.

The company changes fast when the market changes.

Hengfeng helps with setup and repairs everywhere.

Training and tech help keep machines working well.

Factories that choose the right machine and use Hengfeng’s help can grow and do well in making cups.

Disposable Cup Thermoforming Machines help factories make cups fast. They use less energy than older machines. The table below shows important features to think about:

| Feature | Details |

|---|---|

| Production Speed | Makes up to 12,000 cups every hour |

| Material Compatibility | Works with PP, PET, PS, PLA, or paper rolls |

| Automation Levels | Comes in semi-automatic and fully automatic |

Hengfeng’s machines save 30% more energy than old ones. They work with many materials and fit most factory needs. Companies should pick machines with good certifications and energy-saving parts. It is smart to choose machines that can be changed for your needs. Keeping machines clean and picking the right materials helps stop problems like broken or bad cups.

Tip: Pick a machine that fits your goals and can grow with your company.

Hengfeng’s Multistation Thermoforming Machine can use PP, PS, PET, and PLA. These materials let factories make cups for hot drinks, cold drinks, and green products.

The machine can run up to 50 cycles each minute. This means factories can make thousands of cups every hour. It helps them finish big orders fast.

Yes. Hengfeng can make machines for special cup shapes and sizes. The company listens to what customers want and changes machines for special jobs.

Hengfeng gives help all over the world. The team helps set up, teaches workers, and fixes machines. Customers can ask Hengfeng for quick answers and tech help.

Automation uses sensors and smart controls. These tools help keep every cup the same and stop mistakes. Factories get better cups and waste less.